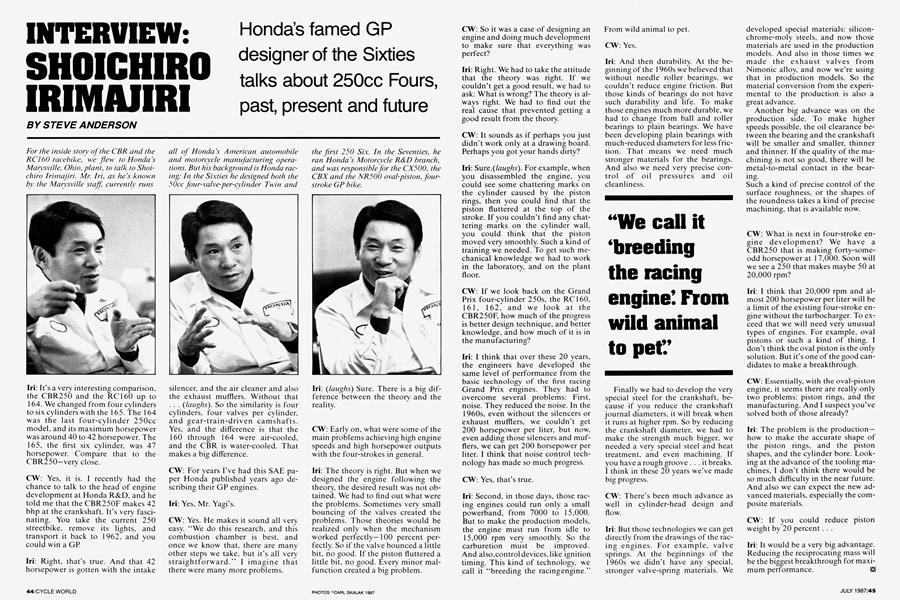

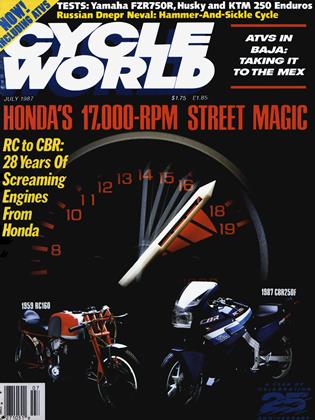

INTERVIEW: SHOICHIRO IRIMAJIRI

Honda’s famed GP designer of the Sixties talks about 250cc Fours, past, present and future

STEVE ANDERSON

For the inside story of the CBR and the RC160 racebike, we flew to Honda's Marysville, Ohio, plant, to talk to Shoichiro Irimajiri. Mr. Iri, as he's known by the Marysville staff, currently runs all of Honda's American automobile and motorcycle manufacturing operations. But his background is Honda racing: In the Sixties he designed both the 50cc four-valve-per-cylinder Twin and the first 250 Six. In the Seventies, he ran Honda's Motorcycle R&D branch, and was responsible for the CX500, the CBX and the NR500 oval-piston, fourstroke GP bike.

Iri: It’s a very interesting comparison, the CBR250 and the RC160 up to 164. We changed from four cylinders to six cylinders with the 165. The 164 was the last four-cylinder 250cc model, and its maximum horsepower was around 40 to 42 horsepower. The 165, the first six cylinder, was 47 horsepower. Compare that to the CBR250—very close.

CW: Yes, it is. I recently had the chance to talk to the head of engine development at Honda R&D, and he told me that the CBR250F makes 42 bhp at the crankshaft. It’s very fascinating. You take the current 250 streetbike, remove its lights, and transport it back to 1962, and you could win a GP.

Iri: Right, that’s true. And that 42 horsepower is gotten with the intake

silencer, and the air cleaner and also the exhaust mufflers. Without that . . . {laughs). So the similarity is four cylinders, four valves per cylinder, and gear-train-driven camshafts. Yes, and the difference is that the 160 through 164 were air-cooled, and the CBR is water-cooled. That makes a big difference.

CW: For years I’ve had this SAE paper Honda published years ago describing their GP engines.

Iri: Yes, Mr. Yagi’s.

CW: Yes. He makes it sound all very easy. “We do this research, and this combustion chamber is best, and once we know that, there are many other steps we take, but it’s all very straightforward.’’ I imagine that there were many more problems.

Iri: {laughs) Sure. There is a big difference between the theory and the reality.

CW: Early on, what were some of the main problems achieving high engine speeds and high horsepower outputs with the four-strokes in general.

Iri: The theory is right. But when we designed the engine following the theory, the desired result was not obtained. We had to find out what were the problems. Sometimes very small bouncing of the valves created the problems. Those theories would be realized only when the mechanism worked perfectly—100 percent perfectly. So if the valve bounced a little bit, no good. If the piston fluttered a little bit, no good. Every minor malfunction created a big problem.

CW: So it was a case of designing an engine and doing much development to make sure that everything was perfect?

Iri: Right. We had to take the attitude that the theory was right. If we couldn’t get a good result, we had to ask: What is wrong? The theory is always right. We had to find out the real cause that prevented getting a good result from the theory.

CW: It sounds as if perhaps you just didn’t work only at a drawing board. Perhaps you got your hands dirty?

Iri: Sur ^.(laughs). For example, when you disassembled the engine, you could see some chattering marks on the cylinder caused by the piston rings, then you could find that the piston fluttered at the top of the stroke. If you couldn’t find any chattering marks on the cylinder wall, you could think that the piston moved very smoothly. Such a kind of training we needed. To get such mechanical knowledge we had to work in the laboratory, and on the plant floor.

CW: If we look back on the Grand Prix four-cylinder 250s, the RC160, 161, 162, and we look at the CBR250F, how much of the progress is better design technique, and better knowledge, and how much of it is in the manufacturing?

Iri: I think that over these 20 years, the engineers have developed the same level of performance from the basic technology of the first racing Grand Prix engines. They had to overcome several problems: First, noise. They reduced the noise. In the 1960s, even without the silencers or exhaust mufflers, we couldn’t get 200 horsepower per liter, but now, even adding those silencers and mufflers, we can get 200 horsepower per liter. I think that noise control technology has made so much progress.

CW: Yes, that’s true.

Iri: Second, in those days, those racing engines could run only a small powerband, from 7000 to 15,000. But to make the production models, the engine must run from idle to 15,000 rpm very smoothly. So the carburetion must be improved. And also,control devices, like ignition timing. This kind of technology, we call it “breeding the racingengine.’’

From wild animal to pet.

CW: Yes.

Iri: And then durability. At the beginning of the 1960s we believed that without needle roller bearings, we couldn’t reduce engine friction. But those kinds of bearings do not have such durability and life. To make those engines much more durable, we had to change from ball and roller bearings to plain bearings. We have been developing plain bearings with much-reduced diameters for less friction. That means we need much stronger materials for the bearings. And also we need very precise control of oil pressures and oil cleanliness.

Finally we had to develop the very special steel for the crankshaft, because if you reduce the crankshaft journal diameters, it will break when it runs at higher rpm. So by reducing the crankshaft diameter, we had to make the strength much bigger, we needed a very special steel and heat treatment, and even machining. If you have a rough groove ... it breaks. I think in these 20 years we’ve made big progress.

CW: There’s been much advance as well in cylinder-head design and flow.

Iri: But those technologies we can get directly from the drawings of the racing engines. For example, valve springs. At the beginnings of the 1960s we didn’t have any special, stronger valve-spring materials. We developed special materials: siliconchrome-moly steels, and now those materials are used in the production models. And also in those times we made the exhaust valves from Nimonic alloy, and now we’re using that in production models. So the material conversion from the experimental to the production is also a great advance.

Another big advance was on the production side. To make higher speeds possible, the oil clearance between the bearing and the crankshaft will be smaller and smaller, thinner and thinner. If the quality of the machining is not so good, there will be metal-to-metal contact in the bearing.

Such a kind of precise control of the surface roughness, or the shapes of the roundness takes a kind of precise machining, that is available now.

CW: What is next in four-stroke engine development? We have a CBR250 that is making forty-someodd horsepower at 17,000. Soon will we see a 250 that makes maybe 50 at 20,000 rpm?

Iri: I think that 20,000 rpm and almost 200 horsepower per liter will be a limit of the existing four-stroke engine without the turbocharger. To exceed that we will need very unusual types of engines. For example, oval pistons or such a kind of thing. I don’t think the oval piston is the only solution. But it’s one of the good candidates to make a breakthrough.

CW: Essentially, with the oval-piston engine, it seems there are really only two problems: piston rings, and the manufacturing. And I suspect you’ve solved both of those already?

Iri: The problem is the productionhow to make the accurate shape of the piston rings, and the piston shapes, and the cylinder bore. Looking at the advance of the tooling machines, I don’t think there would be so much difficulty in the near future. And also we can expect the new advanced materials, especially the composite materials.

CW: If you could reduce piston weight by 20 percent. . .

Iri: It would be a very big advantage. Reducing the reciprocating mass will be the biggest breakthrough for maximum performance.

“We call it ‘breeding the racing engine! From wild animal to pet."

View Full Issue

View Full Issue

More From This Issue

-

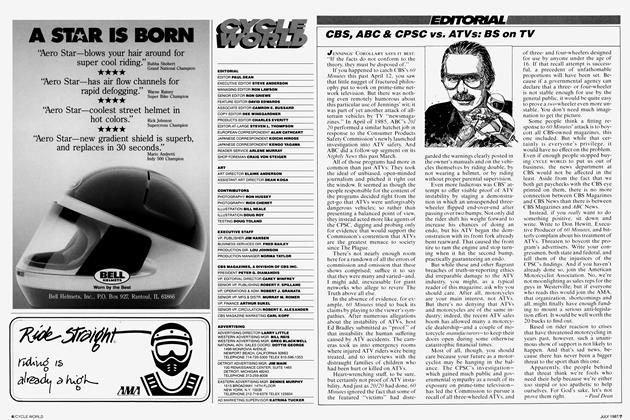

Editorial

EditorialCbs, Abc & Cpsc Vs. Atvs: Bs On Tv

July 1987 By Paul Dean -

At Large

At LargeOld Guys, Rockers And Rockets

July 1987 By Steven L. Thompson -

Departments

DepartmentsLetters

July 1987 -

Roundup

RoundupCpsc Vs. Atvs: Chronology of A Crisis

July 1987 -

Roundup

RoundupSuzuki: Stayin' Alive With the Samurai

July 1987 -

Roundup

RoundupLetter From Japan

July 1987 By Kengo Yagawa