HOW Motorcycles WORK 3

THE FRICTION CLUTCH

STEVE ANDERSON

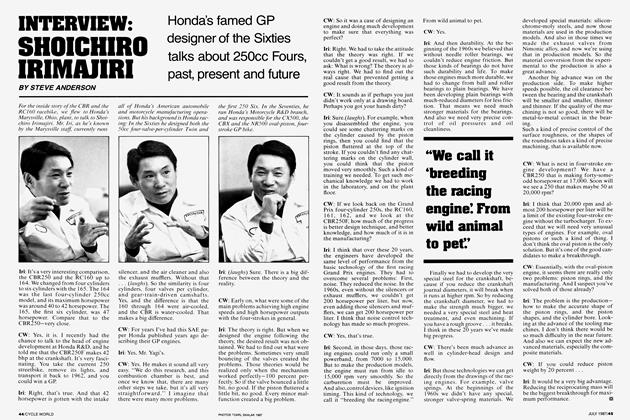

While the Nighthawk 650's engine screams, Pee Wee Gleason waits. The dragstrip lights flash yellow yellow green and the Nighthawk jumps off the line, tach needle on the peg as Gleason slips the clutch, feeding the rear tire as much power as it will take. The front wheel lifts but Gleason doesn't back off. Instead, he slips the clutch a bit more. The exhaust note rises in pitch, the front wheel drifts back to earth and the bike disappears down the strip, no power wasted. Gleason is four-tenths of a second quicker than anybody else.

Listening to Gleason at work gives a clue to one source of his speed. The first 100 feet of a Gleason pass sounds dif ferent. There's no steady rise in engine note, but rather a quivering wail as the engine gains or loses revs in response to Gleason's manipulation of the clutch. The throttle is al ways wide open and the en gine is always at peak power. The clutch has become the control that parcels out the power. If the tire or chassis can’t cope, the slipped clutch diverts engine output, storing the excess energy in a faster spinning crank, then sending it back through the drivetrain when it can once again be used for acceleration.

It ain’t easy, being a clutch.

Gleason is a master of his craft. In a sense, he’s not using the clutch as a clutch. Instead, thanks to the capabilities built into the clutch by years of work, experiment and plain abuse, in a skilled drag racer’s hand the clutch is really more like a variable ratio gearbox, perfectly matching engine speed and output with what the machine can put to good use, i.e. hustling on down the strip.

Of course few motorcycles are s u b -jected to the extremes of drag racing. Even so, transmitting 70 or 100 bhp with nothing more than a few discs held together by springs is a rough job. The wonder is that a clutch can survive at all, never mind that modern motorcycle clutches will live through almost infinite amounts of normal use.

Clutches weren't originally intended to be dragstrip tools. The earliest motorcycles didn’t use clutches at all. Their engines drove the rear wheel directly through a leather belt, requiring tolerance from their riders. Whenever the bike moved, the engine turned. Starts were made by running alongside. Stops required the engine to be stopped as well. If the bike went faster, the engine turned faster, with no gearing to change the ratio between engine and road speed. Before motorcycles could progress beyond this motorized bicycle stage, some means was required to disconnect the engine from the rear wheel.

That means was (and is) a clutch. By definition, a clutch is any mechanical device that allows one rotating part to be disconnected from another. That definition includes positive mechanical connections (dog clutches, as used inside gearboxes, for instance), but when “clutch” is used to describe a motorcycle part, it usually refers to friction clutch, a type of clutch that depends on the friction between parts pressed together to transmit power. Friction clutches, unlike their positive counterparts, offer gradual engagement and the possibility of smooth starts.

The first clutch used on a motorcycle was the leather drive belt itself. A tensioner wheel was added to control the tightness of the leather belt. The position of the tensioner wheel was controllable by a hand lever. By slacking olí the belt tension, the engine could be started without the motorcycle running away. With the engine started, the rider could slowly engage the tensioner wheel. The belt would slip slightly initially, allowing the motorcycle to accelerate. Then the tensioner wheel could be locked into the full tight position, ending the slippage.

The leather belt/tensioner wheel arrangement was preferable to no clutch at all, but it was cumbersome and limited by the small amount of power the belt would transmit before slipping, even when fully tensioned. It also didn't lend itself to use with a gearbox. A better clutch was needed.

The need was met by the disc clutch. The operating principles behind it are simple. Imagine trying to take power off the end of a spinning crankshaft. You could simply push another shaft against the end and set the second shaft spinning. Power would be limited by the slippage that occurs when the load overcomes the friction between the two shafts. Pushing the shafts together harder would generate larger friction forces, delaying the slippage until a higher load was added. The same effect could be created by leaving the force pushing the two shafts together alone, and instead increasing the shaft diameters. This would give the friction forces more leverage, increasing the torque that could be transmitted just as a longer breaker bar increases the torque that can be exerted on a bolt.

This is the essential idea behind the single disc friction clutch. Instead of using large diameter shafts, the shafts' ends have large diameter discs attached, to provide the extra leverage without wasting material. Actual single disc clutches never use a single disc (two is the minimum required), and more typically use three. In automotive terminology, the disc on the end of the crankshaft is the flywheel. The next disc, attached to the transmission, is the clutch disc. Behind it is the third disc, the pressure plate. It’s keyed to the flywheel on its outer edge, and has a hole in the center for the transmission shaft to pass through. Springs push the pressure plate toward the flywheel, trapping the clutch disc in between. A separate mechanism pushes the pressure plate aw'ay from the flywheel and clutch disc to disengage the clutch.

A friction clutch isn’t strictly limited by the amount of power it can transmit, but rather by how much torque it can withstand without slipping. Torque is the twisting force trying to turn a shaft, regardless of how fast the shaft is already turning. Power is a product of torque and speed. At a constant torque level, power increases linearly as speed increases. A clutch can transmit more power the faster it’s turning, but as soon as the torque level is greater than the friction forces holding the discs together, the clutch slips.

The torque/power distinction isn't as important for cars as motorcycles. Most cars have their clutches turning at crankshaft speed, while that's true of only a few motorcycles. Most motorcycles use a speed reduction between engine and clutch, a speed reduction that multiplies the torque the clutch must withstand. Motorcycle clutches are thus given a harder task than their automotive cousins.

A motorcycle clutch must be able to transmit the greatest torque its engine can produce and its primary drive can multiply, must disengage using only the force a rider’s left hand can exert, must withstand enough slippage to allow a smooth start, must have this slippage closely related to clutch lever position or force, and must do all this while being reliable, compact, quiet, and not overly costly. These are the constraints that shape motorcycle clutch design.

Start with the amount of torque a disc clutch can transmit. This is determined by the spring force holding the plates together, by the diameter of the plates, by the coefficient of friction of the plate materials, and by the number of friction surfaces. The formula that relates these factors is: torque capacity = effective radius x spring force x coefficient of friction x number of friction surfaces.

Time out for definitions. Coefficient of friction is a term used to describe how two materials pushed together will resist movement. It’s defined to be the ratio of the sideways force required to move the two materials relative to the force pushing them together. Take the case of a one pound block on a flat surface, with only the block’s weight holding it in place. If it took a half pound push to move the block sideways, the friction coefficient would be 0.5. If it took two pounds of force to move the block, the coefficient would be 2.0. If you covered the surface with oil, it might only take a tenth of a pound to move the block, and the coefficient would be 0.1. The more slippery the two surfaces are, the lower the coefficient.

By moving the friction surface of a clutch farther away from the center, that surface has more leverage on the central shaft. That’s known as effective radius. The greater the effective radius, the more torque the clutch plate can transmit. The friction force itself is basically independent of clutch disc area, so the most efficient clutch disc is a thin ring, a shape that concentrates disc area towards the outer edge. This gives the greatest effective radius for a given outside diameter, and therefore the greatest torque capacity. (A quick approximation for effective radius of a ring-shaped clutch plate is half the average of the internal and external diameters.)

Torque capacity is the first consideration in a motorcycle clutch, and providing enough capacity influences the rest of the clutch design. On most motorcycles, there’s a definite limit to how big the clutch diameter can be (limiting effective radius), and there’s another limit to how hard a rider can or wants to squeeze a clutch lever (limiting spring force). In a single-disc clutch, that leaves coefficient of friction as the key to capacity. Unfortunately, the materials used to make up the plates can’t be chosen just on the basis of their friction characteristics. Durability is a consideration as well; the discs have to tolerate the heat generated by slippage, and have to be resistant to wear. The choice is very similar to the choices offered by tires: there are racing tires that offer ultimate traction, along with a short life. Then there are touring tires that offer more life but don’t stick as well.

The most durable clutch disc material is metal, with mating discs made of dissimilar metals to prevent galling and welding caused by slip-induced heat. Much like touring tires, this combination isn’t the stickiest, with a coefficient of friction around 0.15.

Even in the earliest days, there were stickier materials available. Clutches were lined with leather or compressed cork. Glued to a metal clutch disc and acting against another metal disc, either of these materials could easily double the torque capacity of a metal-to-metal clutch, all from improved friction coefficient. The drawback was sensitivity to slip generated heat. Clutch slip would heat up the cork or leather surface until it started to carbonize and deteriorate. Coefficient of friction would drop, which would lead to increased clutch slippage, which would cause more deterioration, which . . . the cycle would continue until the clutch was destroyed.

Current clutch linings offer more heat resistance along with higher friction coefficients. Woven asbestos (and sometimes fine wire or metal chips) is impregnated with a binder of rubber or plastic. These linings can offer a friction coefficient approaching 0.5 (more than three times higher than metal-on-metal), and survive temperatures hundreds of degrees higher than leather or cork.

Clutch design must allow for the heat resistance and other properties of the friction materials. Slip generates heat, increasing with higher pressures and speed differences between the clutch discs. Enough clutch disc area must be provided to maintain low unit pressures on the friction material, and clutch diameter can’t be so large that sliding speeds burn up everything. This is particularly critical for the organic linings (the generic name for the leather, cork, and asbestos/plastic friction materials), as the best of them won’t withstand much over 40 psi and sliding speeds over 7500 feet per minute. Metal-on-metal clutches will tolerate far higher pressures and speeds, but they’ll make enough heat doing it to be a problem. For any clutch, either organic or metal-onmetal, to be abuse tolerant, it has to have enough disc area to distribute the heat, and a means of ridding the clutch of the heat. That has led to airor oil-cooling of clutches.

Oil-cooling may seem an unlikely prospect, for it would reduce friction coefficient. On metal-on-metal clutches it does, but less for organically lined clutches. Because they’re the ones most in need of cooling, and because it’s so mechanically convenient to cool the clutch with the same oil that lubricates the primary drive, oil cooled organic clutches are almost a motorcycle standard.

Air-cooled clutches are used on some racebikes, and are known as dry clutches, but not every dry clutch is air cooled. The dry clutch in the first Harley Sportsters was sealed to keep oil off the plates. The heat path is long, but the size of the clutch and nature of its use keep it from overheating. The semi-dry clutch of the 74 and 80 c.i.d. Harley engines runs in a primary drive case with a very low oil level. This clutch doesn’t use direct oil cooling, but can be cooled better than the sealed dry clutch.

The need for high torque capacity in a compact package can’t be met by just the use of high-friction clutch materials; motorcycles depart from most automotive practice by using clutches with more than a single clutch disc. Accordingly, they’re known as multi-disc clutches. The advantage over a single-d;sc clutch is a higher torque capacity without increasing diameter or spring pressure. A simple experiment will demonstrate the principal involved. Put two pieces of paper on a desk so they half overlap, and set a weight over the overlap. Now pull them apart and notice how hard you have to pull. Try it again, but with 10 sheets of paper stacked so they alternatively overlap. The force required to pull them all apart at once has increased substantially, while the weight holding them together has remained the same. The increase in force directly corresponds to the increase in the number of sheets. This works for clutches as well, and the multi-disc design with its high torque capacity is almost mandatory on motorcycles. It allows the use of a small diameter clutch that packages well behind the engine without the use of clutch springs that’ll force the development of a real he-man grip

Multi-plate wet clutches have one major drawback for some applications: they fail to perform a clutch’s primary function, to completely sever the flow of power. This phenomenon is known as clutch drag, and is caused by oil film between the plates transmitting some power even when the spring load has been removed. Clutch drag is frequently the cause of hard shifting, with the dog clutches in the transmission reluctant to release while still lightly loaded. Transmissions often take the blame for what is actually a clutch defect.

Clutches drag more when the oil in which they’re operating is cold and thick, so the problem is worse right after starting a motorcycle. It can be compounded because some clutch lining materials in combination with some engine oils literally glue themselves to their adjacent metal plates. This explains the initial lurch some motorcycles make when first dropped into gear in the morning; it’s the jerk as the clutch plates first grab and then break loose.

Roadracing motorcycles frequently use multi-plate dry clutches. Riders like the clean disengagement provided by a dry clutch; wet clutches don’t always respond quickly enough to recover from a sudden engine seizure. Dry clutches with all-metal plates directly exposed to the flow of cooling air offer superb durability and performance. They’re reserved for use on roadracers because they’re more expensive, with additional seals required to keep oil away from the clutch, and because they tend to be noisy, with clutch plates rattling without oil to damp out the noise.

The clutch discs in a multidisc clutch are divided into two categories, the drive and the driven plates. The drive plates fit into the clutch basket and are themselves driven from tabs on their outer diameter. A driven plate fits between each pair of drive plates, and tabs on its inner diameter key into a clutch hub connected to a transmission shaft. A pressure plate, loaded by springs, presses the drive and driven plates together. Clutch disengagement occurs by moving the pressure plate away from the other plates, either by a push or pull rod. The rod, whatever its type, is isolated from pressure plate rotation by a bearing. Somehow movement at the clutch lever has to be translated into movement of the rod. Because space is at a premium in the engine, an amazing array of mechanical answers to rod movement have been used. The simplest use a pivoted lever to translate clutch cable movement into axial clutch rod motion. Other solutions have been cams, or ball screws, or even rack and pinions, all translating clutch cable movement into rod motion. Hydraulic actuation has recently become trendy, with a master cylinder on the handlebar driving a slave cylinder moving the rod moving the pressure plate. The all-mechanical solutions have to provide means of adjusting the clearance between the clutch rod and its actuator to compensate for wear. This adjustment is automatically provided by the free floating slave piston in the hydraulic designs.

For a clutch to be truly useful, it must provide good feel. A rider must be able to control the degree of slippage as a function of clutch lever pressure and position, or else jerky starts and stalled engines result. Position is perhaps most important, and clutch engagement must occur over a broad range of lever position. If a clutch lever moves only a sixteenth of an inch between engagement and full disengagement, riding smoothness will be difficult, if not impossible.

Clutch actuation determines clutch feel. If all the discs in a clutch were rigid and perfectly flat, clutch disengagement would only require the pressure plate move out from the disc pack a few thousandths of an inch. This would be wonderful in reducing clutch lever effort as it would allow a high mechanical leverage ratio to be used, but it would be lousy for feel because it would be impractical to translate the small movement at the pressure plate to a large movement at the lever. In real life, the plates aren’t perfectly flat and offer some compliance as they engage. This allows a more reasonable range of lever travel. If it isn’t enough, some makers (Honda and Yamaha), put in a compliance plate that consists of two allmetal plates with a wave spring in between. The pressure plate has to compress the wave spring before full engagement is reached, stretching engagement over a greater axial movement of the pressure plate, and therefore the clutch lever.

Most multi-plate motorcycle clutches use multiple coil springs to hold the pressure plate against the disc pack. Four is generally the minimum, with six or more often used to distribute the spring force evenly over the pressure plate. This allows the pressure plate to be thinner without warping. Coil springs offer a linear spring rate, that is, they deflect the same increment for each additional increment of force. When used in a clutch, they’re preloaded by an inital compression far more than they move during disengagement. The result is a fairly constant force required to pull in the hand lever: it starts at the preload value, and then increases slightly as the lever approaches the handlebar.

Diaphragm clutch springs offer different characteristics that can be used beneficially in a clutch. A diaphragm spring looks like a shallow cone with its tip cut off. Deflection occurs as the cone shape is flattened to a washer, and is strongly nonlinear. The initial movement is hard, and grows easier the flatter the diaphragm is made. Harley, BMW and Honda have recently used this type of spring in clutches to provide a decreasing clutch lever pull; in the case of the Harley Sportster; it takes less than a third of the effort to hold the clutch lever against the grip as it as it did to pull it in initially. While desirable, this isn’t exactly a new idea. Norton Commandos adopted this scheme in 1968, and it was automotive practice long before that.

Clutches aren’t a motorcycle mechanism where exciting progress is likely; they work so well already it’s only the extreme abuse of dragstrip acceleration that brings out any complaints. More likely is continued evolution, with better feel during clutch operation and the elimination of clutch drag having higher priorities than any new capabilities. Perhaps the best parts are the ones that function so well they’re never noticed. Clutches are already close to that.

View Full Issue

View Full Issue

More From This Issue

-

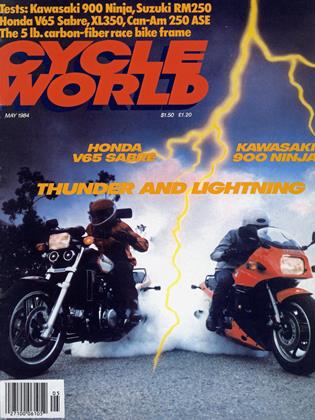

Up Front

Up FrontMy Farewell Address

May 1984 By Allan Girdler -

Cycle World Letters

Cycle World LettersCycle World Letters

May 1984 -

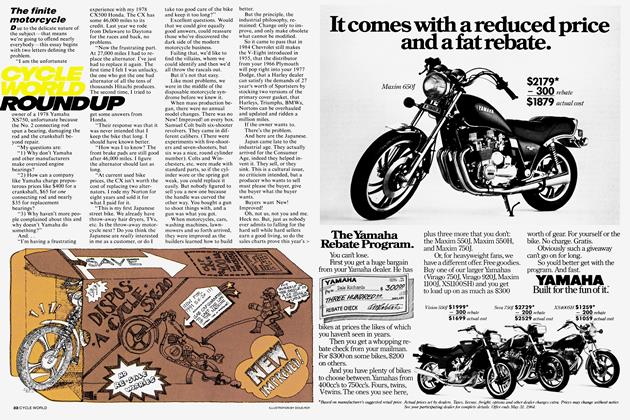

Departments

DepartmentsCycle World Round Up

May 1984 -

Features

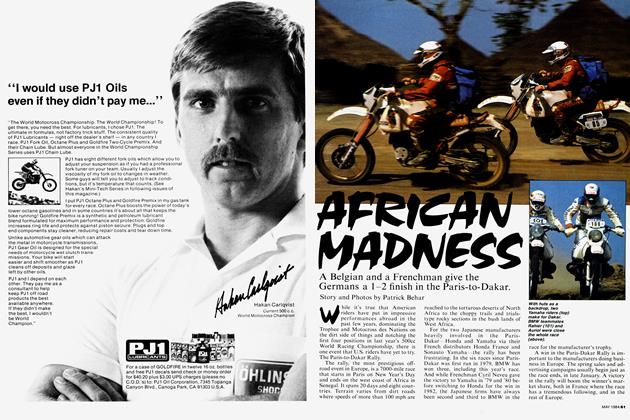

FeaturesAfrican Madness

May 1984 By Patrick Behar -

Competition

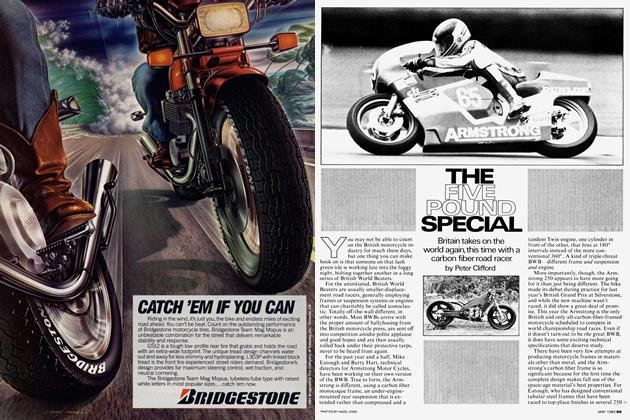

CompetitionThe Five Pound Special

May 1984 By Peter Clifford -

Competition

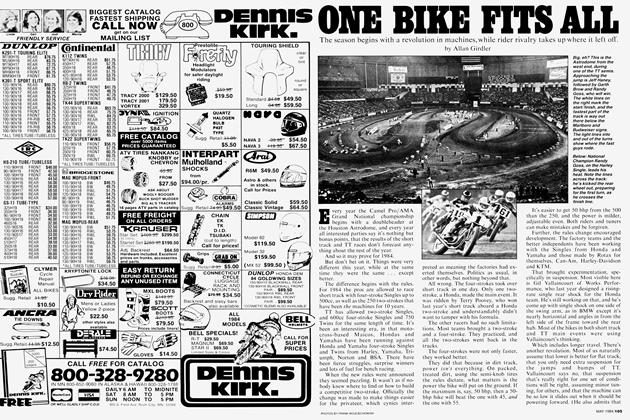

CompetitionOne Bike Fits All

May 1984 By Allan Girdler