CYCLE WORLD SERVICE

Mikuni carbs for Triumph Twins

I am the owner of a 1977 Triumph T140V and would like to switch to Mikuni carbs. Could you tell me where I could purchase a set for my bike?

Michael McKee Taylorville, 111.

There are at least two sources for a Mikuni conversion kit. Big D Triumph (3600 West Davis, Dallas, Texas 75211, (214) 339-2285) offers a $200 kit that consists of two Mikuni carbs, intake tubes, air cleaners, twist grip, and throttle cables. The carbs are jetted for Triumph applications, and shouldn’t require any more than fine tuning for your motorcycle.

A similar package is sold by Sudco International (1824 E. 22nd St., Los Angeles, Calif. 90058, (213) 747-5173). The Sudco kit costs more ($250 or so suggested retail) and offers essentially the same parts without the twist grip and cables; Sudco recommends using the stock Triumph throttle with a special throttle cable available from Barnett.

Shiny black engines

#?egarding Mr. Bradley’s query in November Service on the cleaning and polishing of black engines, I have found that Armor-All, when sprayed on a slightly warm engine and allowed to dry, will protect and shine cases and fins. It also works on black surfaces such as instrument cases, brake calipers, wheels, etc. Just spray it on, allow it to dry, rinse with a hose, and towel dry. It doesn’t leave an oily film to collect dirt and the protective film makes it more difficult for road tar to adhere to the engine. It works.

Gary Hagen

Signal Hill, Calif.

Case protectors and motocrossers

Almost all current motocrossers (and many enduro bikes as well) have a flat steel arc-shaped piece surrounding the front of the countershaft sprocket and bolted to to the engine center cases. Its purpose is to prevent a broken chain from jamming between the sprocket and cases and punching a hole. Unfortunately, a broken chain often jams between the sprocket and the so-called case protector with even worse results. The bosses cast into the crankcase to hold the case protector are broken off, leaving a gaping hole in the transmission section of the engine cases, an area where a weld repair is likely to distort a bearing housing.

On motocross bikes kept for long-term tests, we’ve tried removing the protectors. So far we’ve found that a broken chain may damage a magneto cover or the cases in that area, but the result is less disastrous and easier to repair than it would be with the protector in place.

Sportster vibration

The enjoyment of finally getting a beautiful 1977 XLCR Harley-Davidson is compromised by its inherent vibration at highway speeds. Following grip and sprocket changes, I am still searching for relief. Recently I thought r. I had learned of a solution, belt conversion of the primary drive, only to again be denied. When I took my XLCR to m) mechanic I was advised noi to attempt such a conversion on a Sportster engine, as these engines are designed to rhave the primary drive run wet, which results in premature belt failure. Calls to Chicago area H-D dealers saw the same results, that is, either they would not do Sportster belt conversions or -'they had never done them because of others’ bad experiences. My questions are: Is such a conversion practical on my bike? If not, why not?

Are there companies with a proven track record in producing Sportster conversion kits?

Theodore W. Polonus Chicago, 111.

We’d side with your mechanic in advising against the ^conversion. First, belt drive, even if it were reliable, won’t eliminate your bike’s vibration problems. Those are caused by unbalanced piston forces, forces that will shake the bike if they’re not cancelled by counterbalancers or isolated with rubber mounts. Second, primary drive is a marginal application for belt conversions. Belts require more space than an equivalently strong chain, and it’s only in cases like the Harley big Twin that have room for a wide belt where the conversion is likely to be successful. For it to work in a late model Sportster, the primary drive area would have to be sealed from gearbox oil, a dry clutch would have to be adapted, and a new primary cover that allows a wide belt would have to be added. We think that’s too much work for any potential benefits.

The only approach we’ve seen effective for minimizing Sportster vibration is taller gearing. Sportsters are relatively smooth under 3000 rpm, and if you use gearing that matches that engine speed to about 75 mph road speed, highway cruising can be comfortable. A Sportster will pull gearing this tall, but its acceleration will be compromised.

Oil-covered timing light

/own a 1983 Honda XR350. Even under light usage on cold days the engine seems to run hot. Can you shed any light in this area? I would especially like to check the basic timing to see if it’s right at low rpm and to see if the advance curve is correct at higher rpm. How do you put a timing light up close to the little inspection hole? All I get is oil spray.

Al Borelli

Felton, Calif

Checking the timing on the XR/XL motors can be a mess, as Honda representatives will admit. Our contact at Honda suggests two approaches: the first is to keep oil away from the ignition rotor by dropping the oil level to the lowest mark on the dipstick and having a friend lean the bike over to the right when you check the timing. The second recommendation is to cover the inspection hole with a piece of clear plexiglass.

All of the larger wet sump Honda XR/XL engines tend to run hot when ridden hard, so there may not be anything unusual about your bike. If the timing checks out and the bike runs well, we wouldn’t do any thing except change the oil more often than the shop manual recommends.

Big bore 550, part II

In the November 1982, Service column, there was a letter titled Big Bore GS550. Peter Gay wanted to know if he could put GS650 parts on his 550. Your reply was that a Suzuki rep said no way. I’m glad I didn’t read that letter last year, because at the exact time I was bolting 650 parts on my 1979 GS550L. I purchased a burned 650 from a local salvage yard for a low, low price. The 650 cylinder block slid on with only minor grinding on the 550 cases. The pistons fit the rods, the head bolted on, and the cams fit with the use of 550 cam sprockets. Degreeing of the cams is advisable, but not really necessary. The ends of the 550 exhaust need to be sleeved to match the 650 ports, or the 650 exhaust can be used. 1980 and later carburetion was a bolt on

continued on page 92

continued from page 89

with only jetting changes required.

This swap was easy and inexpensive, and well worth the time spent in a cold garage while the snow piled up outside. 650 power and 550 insurance rates were the result, all at a bargain price.

David S. Young Ogden, Utah

As usual, you can accomplish more if someone hasn’t told you it’s impossible. Thanks for the new information.

Prehistoric carb synchronization

I ride a Honda CB350E Twin which I think is a 1971 model. What I would like to know is how to synchronize the twin Keihin carbs. I have been unable to synchronize these carbs as there are no outlets for attaching a vacuum operated carb synchronizer. Incidentally my problem is rough idling and uneven throttle response.

Adnan A. Agha

Karachi, Pakistan

It’s amazing how quickly new technology drives out the old; 15 years ago motorcyclists wouldn’t have known how to synch carbs with a set of vacuum gauges. Here’s how it was done then: Back off the idle stop on each carb until the throttle butterfly closes completely. Adjust the throttle cable free play on each side so that both butterflys start opening at the same time. You can check this by putting your left hand on the left carb butterfly lever, leaning over the bike and watching the lever on the right carb, and opening the throttle with your right hand. When the cables are adjusted correctly, you should feel the left lever start moving at the same time you see the right lever move. The carbs are now synched. Set the idle by turning both idle stop screws in the same number of turns from the point where each screw makes contact with its carb body, and fine tune the idle adjustment by feeling the strength of the exhaust pulses coming from each exhaust pipe; they should be equally strong.

Alternative methods to synch the carbs would be to drill and tap holes in the inlet tubes to use vacuum gauges, or to use a Uni-Syn tool. More familiar to British sports car drivers than motorcyclists, the Uni-Syn fits over a carb’s mouth and gives a reading based on the vacuum level. It requires air filter hoses be removed for access.

If carb synchronization doesn’t cure your rough idling and poor throttle

response, the problem is deeper rooted. Valve misadjust ment, leaky rings or valves, a torn carb diaphragm, or a plugged low speed jet could all be responsible for your bike’s poor running.

Clicking Venture

I am presently riding a new Venture and am curious to know if the Venture you tested had an annoying click in the front forks during low speed riding on washboard roads, over railroad tracks, manhole covers, etc. Or is this noise apparent only on my Venture? Also, did you notice that temperature of the Venture climbing a bit high in town? Mine gets close to the red zone when riding in slow traffic.

Joseph L. Kintz

Mechanicsburg, Penn.

Yes, our test Venture exhibited some front end noises on bumpy surfaces. When the fork air pressure was set near 'maximum, the forks would top out and a clicking noise could be heard. This noise apparently comes from the steering head bearings and can be eliminated through proper adjustment of the bearings. You can also reduce it by lowering air pressure.

Water-cooled bikes often tend to run hot when ridden in slow traffic (As do air-cooled bikes, but they don’t have a temperature gauge to worry you). As long as the electric fan is switching on as the needle climbs, and the bike isn’t running in the red zone or boiling over, hot running in traffic is normal. El

View Full Issue

View Full Issue

More From This Issue

-

Departments

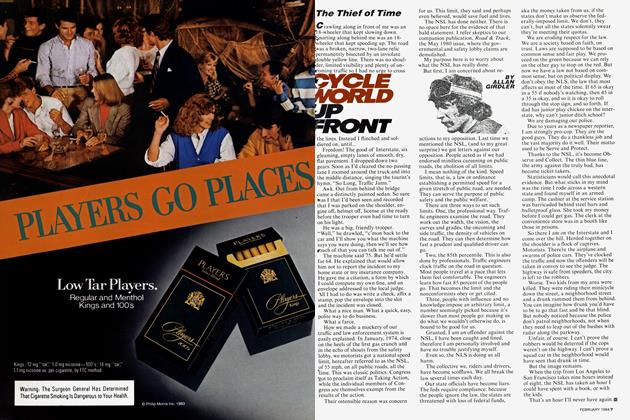

DepartmentsCycle World Up Front

FEBRUARY 1984 By Allan Girdler -

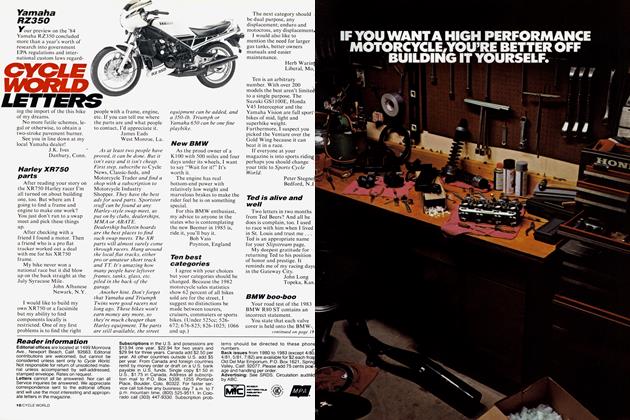

Cycle World Letters

Cycle World LettersCycle World Letters

FEBRUARY 1984 -

Departments

DepartmentsCycle World Book Review

FEBRUARY 1984 By Allan Girdler -

Departments

DepartmentsCycle World Roundup

FEBRUARY 1984 -

Features

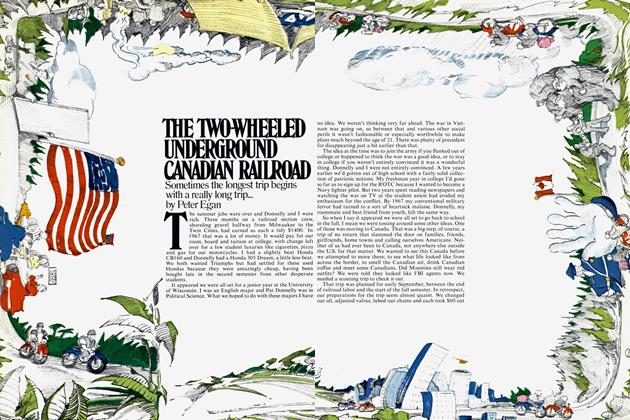

FeaturesThe Two-Wheeled Underground Canadian Railroad

FEBRUARY 1984 By Peter Egan -

The Exotics

The ExoticsAllyou Need Is the Money

FEBRUARY 1984 By John Ulrich