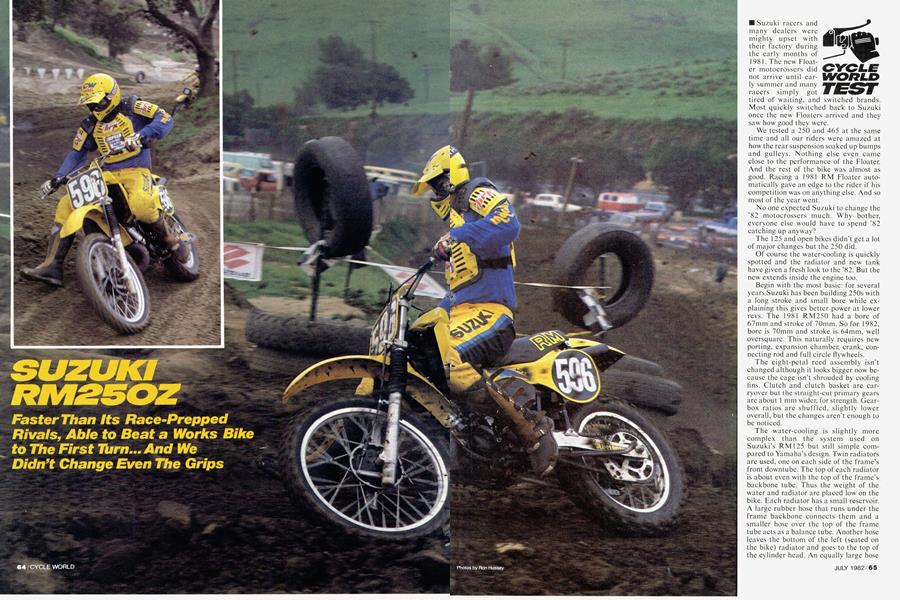

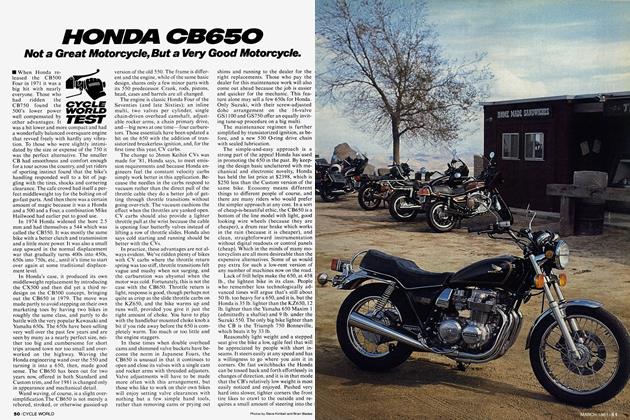

SUZUKI RM250Z

Faster Than Its Race-Prepped Rivals, Able to Beat a Works Bike to The First Turn... And We Didn't Change Even The Grips

CYCLE WORLD TEST

Suzuki racers and many dealers were mighty upset with their factory during the early months of 1981. The new Floater motocrossers did not arrive until early summer and many racers simply got tired of waiting, and switched brands. Most quickly switched back to Suzuki once the new Floaters arrived and they saw how good they were.

We tested a 250 and 465 at the same time and all our riders were amazed at how the rear suspension soaked up bumps and gulleys. Nothing else even came close to the performance of the Floater. And the rest of the bike was almost as good. Racing a 1981 RM Floater automatically gave an edge to the rider if his competition was on anything else. And so most of the year went.

No one expected Suzuki to change the ’82 motocrossers much. Why bother, everyone else would have to spend ’82 catching up anyway?

The 1 25 and open bikes didn’t get a lot of major changes but the 250 did.

Of course the water-cooling is quickly spotted and the radiator and new tank have given a fresh look to the ’82. But the new extends inside the engine too.

Begin with the most basic: for several years Suzuki has been building 250s with a long stroke and small bore while explaining this gives better power at lower revs. The 1981 RM250 had a bore of 67mm and stroke of 70mm. So for 1982, bore is 70mm and stroke is 64mm, well oversquare. This naturally requires new porting, expansion chamber, crank, connecting rod and full circle flywheels.

The eight-petal reed assembly isn’t changed although it looks bigger now because the cage isn’t shrouded by cooling fins. Clutch and clutch basket are carryover but the straight-cut primary gears are about 1 mm wider, for strength. Gearbox ratios are shuffled, slightly lower overall, but the changes aren’t enough to be noticed.

The water-cooling is slightly more complex than the system used on Suzuki’s RM 125 but still simple compared to Yamaha’s design. Twin radiators are used, one on each side of the frame’s front downtube. The top of each radiator is about even with the top of the frame’s backbone tube. Thus the weight of the water and radiator are placed low on the bike. Each radiator has a small reservoir. A large rubber hose that runs under the frame backbone connects them and a smaller hose over the top of the frame tube acts as a balance tube. Another hose leaves the bottom of the left (seated on the bike) radiator and goes to the top of the cylinder head. An equally large hose exits the bottom of the right side radiator and goes to the top of the primary geardriven waterpump. Water circulates from the left side radiator to the right via the top hose, down the right hose to the pump, from the pump into the bottom of the cylinder, up through the cylinder and head, then out the top of the head and into the bottom of the left radiator to complete the lap. Sounds complicated but it’s actually quite simple and the external hoses aren’t as vulnerable as they are on some designs.

A 38mm Mikuni carburetor is used on the Z. It is a new rectangular slide model that improves engine response and engine performance. Internally the flat-sided slide is the only change. Floats and jet parts are the same as used on the round slide Mikunis. The flat slide provides better response and power by directing the incoming air directly across the top of the needle jet outlet. Round slides direct much of the air to the sides of the carb throat and there’s a loss of pull across the top of the nozzle as a result. The needle is adjusted as it is in round slides, via a wire clip. The needle has five grooves for height changes.

Suzuki’s Full-Floater rear suspension was the best performing of the new single shock systems last year. For ’82 it’s even better. The change to the system isn’t visible, it’s inside the shock. Compression damping has been increased by about 25 percent. That’s it for rear suspension changes. The change has made the rear of the ’82 even better than before.

Suzuki’s Floater suspension is built around a vertically mounted aluminumbodied shock, placed low behind the engine. The bottom of the shock bolts into a bracket below the front of the swing arm, the top bolts to one end of a welded-up aluminum rocker. The rocker is made of stamped aluminum parts welded into a strong, light rocker. The center of the rocker pivots in needle bearings and the pivot shaft runs the width of the frame so load is supported evenly. The rear of the rocker is a wishbone arrangement that allows the use of a strut from each arm to the top front at each side of the swing arm. Other single shock designs have one end of the shock bolted to an unmovable frame member at one end or the other. In the Floater system, the shock is compressed by movable parts at both ends.

The large-bodied shock can be taken apart for oil changes and service and there’s a knob at the top of it that easily adjusts rebound damping to suit rider preference and different track conditions. The small aluminum remote reservoir is placed on the front downtube below the left radiator. Lubricating the linkage arms and swing arm pivot require disassembly but we’ve found from past experience it won’t need it often unless you race a lot in mud. Even then the seals are good and maintenance isn’t frequent.

The swing arm is the same strong extruded aluminum part used last year. It doesn’t flex or break, need modification or special treatment. A hard plastic rub block protects the front part of it from the chain and a works-type aluminumsided chain guide is mounted close to the rear sprocket. The bottom of the chain guide has a long-lasting plastic block and there’s another block on each side of the rear sprocket. These blocks scrape mud from the sides and teeth of the rear sprocket, eliminating some of the problems associated with mud build-up.

Suzuki was one of the few manufacturers not to use forks with 43mm stanchion tubes on production 250cc motocrossers. The ’82 RMs still have 38mm stanchion tubes but they have thicker walled tubes for greater rigidity. In fact the whole fork assembly, with the exception of the triple trees, is new. The lower legs are aluminum tubes with a cap welded on the bottom and axle mounting tabs are shrunkfit to the tubes.

Other changes to the ’82 RM250 are mostly aimed at refining last year’s package. The throttle has a turned cable outlet, the hand levers are doglegged and their lower sides are lightened. Cables are better quality than before, the shift lever finally has a folding tip and the outer air cleaner elements are thicker and slightly larger for better sealing. The airbox is unchanged, with a large air filter on each side of the bike.

Other left-over parts from last year are the wheel assemblies. But no one is going to complain. The RM wheels and hubs, first introduced last year, are the best you can get. The hubs have straight-pull spokes, strong brakes, and the strong aluminum rims are without lips that catch mud. The spokes look too small but even top-level pro motocrossers don’t have any trouble with them coming loose or breaking. The front brake is a single-leading shoe, nearly 6 in. in diameter and the brake arm is long. We think it is the strongest, most predictable and most controllable of any brake on the motocross market.

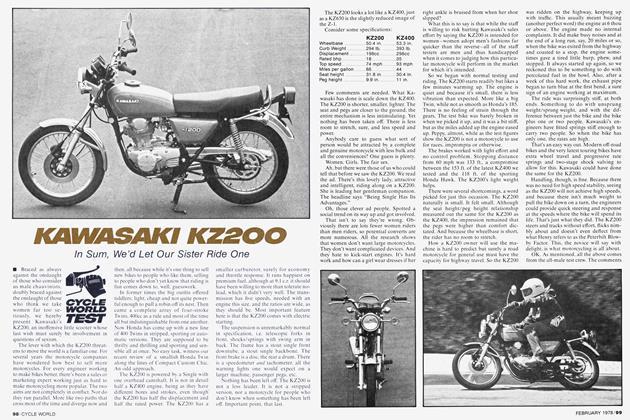

Looking the spec charts over makes you wonder why the ’81 and ’82 RMs work so well. We’ve seen a trend toward long wheelbase with steep rake the past few years, but the RMs have neither. Wheelbase is a modest 58 in., rake is 29.5°, and the RM’s forks give away about an inch of travel to the competitors. So why is the RM so great on the track? First, it simply has the smoothest, most compliant and most forgiving rear suspension made. It doesn’t bottom off the largest jumps, doesn’t jar or beat the rider on the smallest ripples. And it works as well on any size bump or hole or jump or lip in between. Add forks that have nearly perfect track manners, and a flexfree frame and swing arm, and a bike that weighs less than any other production 250 motocrosser, and you start to see why it works so well. While on the subject of weight a few comparisons are in order: The RM250Z is 17 lb. lighter than a YZ250J, 15 lb. lighter than a Honda CR250 and 2 lb. lighter than a new Kawasaki KX250. Next time you’re at the grocery store pick up 15 lbs.; you’ll be amazed at how heavy it is.

The fast engine, super suspension, light weight and the best brakes going, make a racer that clearly has the advantage on the motocross course. And if you are on one, you have an advantage. No, the RM isn’t perfect, but it’s close to it. It is possible to get a little front end wash in slippery corners if the rider doesn’t get up on the tank. And it sometimes takes two kicks to start. That’s it!

If you like riding a good 125 motocrosser, you’ll love the RMZ 250. The light weight and the short stroke engine that likes to rev spell fast lap times and great fun. It’s no secret that a good 125 is the quickest on a tight course. The revving engines and light weight seem to be magic. The 250 RMZ has the same feel and it’ll give the racer a big advantage on tight tracks, or bumpy tracks, or tracks with long starting straights. Or any track.

One of our pro riders raced the test bike at many local pro events. The RM proved super competitive on any type track from slow and tight to long and fast. The bike even pulled Bad Brad’s factory bike on Saddleback’s long uphill starting area! And our tester actually beat Brad in one moto and finished a close second to him in the other. Not bad for an off-thefloor production motocrosser. Of course our man had a little to do with it, but it wouldn’t have been remotely possible on anything but an excellent bike. Remember, this was on a totally stock machine. Nothing had been changed, not even the grips or tires! After the stock tires wore out we replaced the rear with a Metzeler Perfect and the front with a Dunlop K139. The bike is even better now. When we tell you the bike was stock, we really mean it. Absolutely nothing had been changed, even the stock fork oil was in the forks. The rear suspension damping knob was left in the standard No. 2 position, stock spring preload, stock jetting . . . stock.

After several more successful races, mostly wins, we changed the air filters to K&Ns. The K&Ns made the bike even faster and let more air into the engine. One size larger main jet was installed to compensate for the increased air flow. We didn’t cut the airbox covers as many local racers seem to think necessary. The K&Ns with stock airbox covers and one size larger main jet were enough to outdrag all the competition at several highly competitive southern California races.

SUZUKI RM250Z

$2099

Riding position on the RM is about right for most riders. The bars are low over the front of the bike, as they should be for motocross, and the hand and foot controls are the right length and shapes. The footpegs are strong cast steel jobs with good slip-proof claw tops. They are placed high enough on the frame so the rider’s feet aren’t dragged off when landing after sky-shot jumps. One minor complaint logged by our taller test riders: when forward on the bike for tight corners, the plastic shielding on the sides of the radiator catches on the rider’s knee guards. We eliminated the complaint by placing heavy clear plastic, the kind we use to keep stock decals in place, over the junction between the shield and the tank. Thus, the transition of leg from tank to radiator shield was smoothed and no longer bothered taller riders. Another at-

tachment screw for the lower edge of the shield would fix the problem.

As you might suspect, a bike that works as well as the RM250Z wasn’t sitting in the garage very much. The bike has been raced on Saturday and Sunday for the last month. Being so competitive-, at the pro level surprised us. Being competitive at novice and intermediate levels as well raised some eyebrows. And being so in a completely unmodified condition brought wows from other racers. Okay, so the new RM250Z is lightweight, competitive straight from the shipping crate* and any level racer can ride one comfortably. It probably breaks all the time or needs constant maintenance due to its light weight and high power engine, right? Wrong. Not one thing, even a small item, has broken or needed replacement or modification. Nothing. We haven’t^ tested all of the 250 motocrossers avail-^ able for ’82 yet. But if any of them are better than the RM250Z we aren’t aware of them. ES