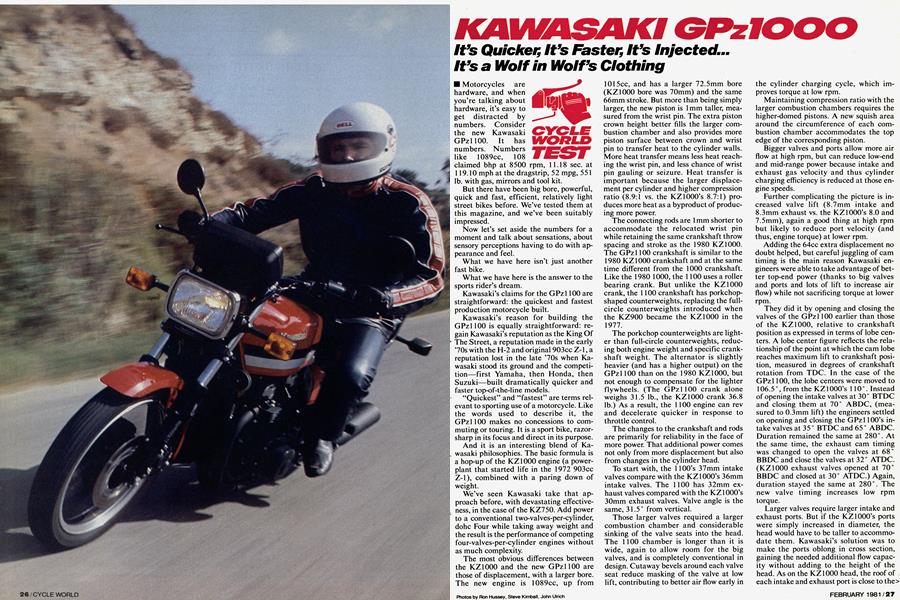

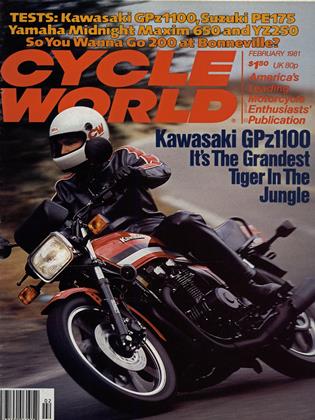

KAWASAKI GPz1000

CYCLE WORLD TEST

It's Quicker, It's Faster, It's Injected... It's a Wolf in Wolf's Clothing

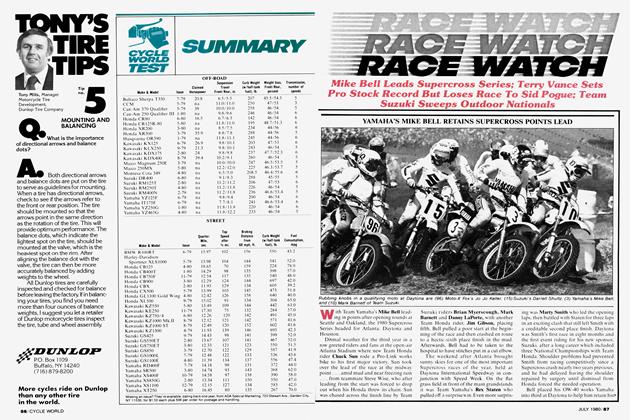

Motorcycles are hardware, and when you're talking about hardware, it's easy to get distracted by numbers. Consider the new Kawasaki GPz1100. It has numbers. Numbers like 1089cc, 108 claimed bhp at 8500 rpm, 11.18 sec. at 119.10 mph at the dragstrip, 52 mpg, 551 lb. with gas, mirrors and tool kit.

But there have been big bore, powerful, quick and fast, efficient, relatively light street bikes before. We’ve tested them at this magazine, and we’ve been suitably impressed.

Now let’s set aside the numbers for a moment and talk about sensations, about sensory perceptions having to do with appearance and feel.

What we have here isn’t just another fast bike.

What we have here is the answer to the sports rider’s dream.

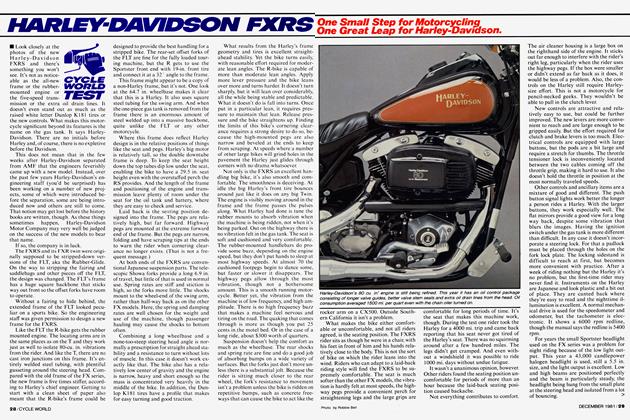

Kawasaki’s claims for the GPzl 100 are straightforward: the quickest and fastest production motorcycle built.

Kawasaki’s reason for building the GPzllOO is equally straightforward: regain Kawasaki’s reputation as the King Of The Street, a reputation made in the early ’70s with the H-2 and original 903cc Z-l, a reputation lost in the late ’70s when Kawasaki stood its ground and the competition—first Yamaha, then Honda, then Suzuki—built dramatically quicker and faster top-of-the-line models.

“Quickest” and “fastest” are terms relevant to sporting use of a motorcycle. Like the words used to describe it, the GPzllOO makes no concessions to commuting or touring. It is a sport bike, razorsharp in its focus and direct in its purpose.

And it is an interesting blend of Kawasaki philosophies. The basic formula is a hop-up of the KZ1000 engine (a powerplant that started life in the 1972 903cc Z-l), combined with a paring down of weight.

We’ve seen Kawasaki take that approach before, with devastating effectiveness, in the case of the KZ750. Add power to a conventional two-valves-per-cylinder, dohc Four while taking away weight and the result is the performance of competing four-valves-per-cylinder engines without as much complexity.

The most obvious differences between the KZ1000 and the new GPzllOO are those of displacement, with a larger bore. The new engine is 1089cc, up from 1015cc, and has a larger 72.5mm bore (KZ1000 bore was 70mm) and the same 66mm stroke. But more than being simply larger, the new piston is 1mm taller, measured from the wrist pin. The extra piston crown height better fills the larger combustion chamber and also provides more piston surface between crown and wrist pin to transfer heat to the cylinder walls. More heat transfer means less heat reaching the wrist pin, and less chance of wrist pin gauling or seizure. Heat transfer is important because the larger displacement per cylinder and higher compression ratio (8.9:1 vs. the KZlOOO’s 8.7:1) produces more heat as a byproduct of producing more power.

The connecting rods are 1 mm shorter to accommodate the relocated wrist pin while retaining the same crankshaft throw spacing and stroke as the 1980 KZ1000. The GPzl 100 crankshaft is similar to the 1980 KZ1000 crankshaft and at the same time different from the 1000 crankshaft. Like the 1980 1000, the 1100 uses a roller bearing crank. But unlike the KZ1000 crank, the 1100 crankshaft has porkchopshaped counterweights, replacing the fullcircle counterweights introduced when the KZ900 became the KZ1000 in the 1977.

The porkchop counterweights are lighter than full-circle counterweights, reducing both engine weight and specific crankshaft weight. The alternator is slightly heavier (and has a higher output) on the GPzllOO than on the 1980 KZ1000, but not enough to compensate for the lighter flywheels. (The GPzllOO crank alone weighs 31.5 lb., the KZ1000 crank 36.8 lb.) As a result, the 1100 engine can rev and decelerate quicker in response to throttle control.

The changes to the crankshaft and rods are primarily for reliability in the face of more power. That additional power comes not only from more displacement but also from changes in the cylinder head.

To start with, the 1100’s 37mm intake valves compare with the KZlOOO’s 36mm intake valves. The 1100 has 32mm exhaust valves compared with the KZlOOO’s 30mm exhaust valves. Valve angle is the same, 31.5° from vertical.

Those larger valves required a larger combustion chamber and considerable sinking of the valve seats into the head. The 1100 chamber is longer than it is wide, again to allow room for the big valves, and is completely conventional in design. Cutaway bevels around each valve seat reduce masking of the valve at low lift, contributing to better air flow early in

the cylinder charging cycle, which im proves torque at low rpm.

Maintaining compression ratio with the larger combustion chambers requires the higher-domed pistons. A new squish area around the circumference of each combustion chamber accommodates the top edge of the corresponding piston.

Bigger valves and ports allow more air flow at high rpm, but can reduce low-end and mid-range power because intake and exhaust gas velocity and thus cylinder charging efficiency is reduced at those engine speeds.

Further complicating the picture is increased valve lift (8.7mm intake and 8.3mm exhaust vs. the KZlOOO’s 8.0 and 7.5mm), again a good thing at high rpm but likely to reduce port velocity (and thus, engine torque) at lower rpm.

Adding the 64cc extra displacement no doubt helped, but careful juggling of cam timing is the main reason Kawasaki engineers were able to take advantage of better top-end power (thanks to big valves and ports and lots of lift to increase air flow) while not sacrificing torque at lower rpm.

They did it by opening and closing the valves of the GPzllOO earlier than those of the KZ1000, relative to crankshaft position as expressed in terms of lobe centers. A lobe center figure reflects the relationship of the point at which the cam lobe reaches maximum lift to crankshaft position, measured in degrees of crankshaft rotation from TDC. In the case of the GPzl 100, the lobe centers were moved to 106.5°, from the KZlOOO’s 110°. Instead of opening the intake valves at 30° BTDC and closing them at 70° ABDC, (measured to 0.3mm lift) the engineers settled on opening and closing the GPzl 100’s intake valves at 35 ° BTDC and 65 ° ABDC. Duration remained the same at 280°. At the same time, the exhaust cam timing was changed to open the valves at 68° BBDC and close the valves at 32° ATDC. (KZ1000 exhaust valves opened at 70° BBDC and closed at 30° ATDC.) Again, duration stayed the same at 280°. The new valve timing increases low rpm torque.

Larger valves require larger intake and exhaust ports. But if the KZlOOO’s ports were simply increased in diameter, the head would have to be taller to accommodate them. Kawasaki’s solution was to make the ports oblong in cross section, gaining the needed additional flow capacity without adding to the height of the head. As on the KZ1000 head, the roof of each intake and exhaust port is close to the> bottom of the corresponding valve spring bore. In the 1100 head, however, the engineers made the port roof thicker by adding a bump of aluminum protruding slightly into the port.

The new head looks as if it will bolt onto the older engine. Bolt positions and external dimensions are identical and camshafts are interchangeable. However, the new bike has an electronic tach operated off the ignition system, so the new exhaust cam lacks a worm gear for the mechanical tach drive used on the KZ1000. The new engine also uses a Hy-Vo type link-plate cam chain with slipper-type cam chain tensioners to match, both for reasons of less mechanical noise, compared to the KZlOOO’s roller chain and tensioner roller system. Gone is the tensioning roller located between the cams on the 1000, and there aren’t mounting points for the other tensioner rollers used in the KZ 10000. While it may not be impossible, getting a new head to fit an old engine will require machine work. The new bike’s cam chain tension is set automatically as well.

The GPz1 100 cylinder assembly is thicker around the larger, 77mm o.d. liners and around the stud bolt holes.

Primary drive in the new engine is still straight-cut gear, with the same 1.73:1 reduction ratio as the KZ1000. But internal ratios in the all-new GPzllOO transmission are different. The gearsets have been sized so that the drive gears have less mechanical advantage on the countershaft gears. For example, in the KZ1000 the first gear ratio was 3.17:1 with a 12-tooth drive gear and a 38-tooth countershaft gear. In the GPzl 100, the first gear ratio is taller, 2.64:1 with a 14-tooth drive gear and a 37-tooth countershaft gear. The other four gearsets show similar ratio changes, which the engineers say will increase durability of the transmission. To compensate for the taller internal ratio alterations, the final drive ratio is lower, 2.73:1 with a 15-tooth countershaft sprocket and a 41-tooth rear wheel sprocket, compared with the KZlOOO’s 2.33:1 (15-tooth countershaft sprocket, 35-tooth wheel sprocket). Overall gearing is almost identical—the GPzllOO turns 3820 rpm at 60 mph, and the KZ1000A turned 3891 rpm at 60 mph.

The GPzl 100’s fifth gearset is 1mm wider than the KZlOOO’s. Each of the other four gearsets is a little narrower to collectively make room for fifth’s extra width. The countershaft journals have been increased from 25mm to 28mm, and the countershaft bearings made larger to match. Like the changes in gear ratios, these changes were made in the interests of reliability, since the 1100 engine makes considerably more power than the 1980 KZ1000 engine did.

A change made for easier shifting is the use of ball bearings for the shift drum to rotate on, compared to bushings used in the KZ1000. The new transmission cannot be used in older model crankcases because the shift drum location is changed (to accommodate its ball bearings) and because the countershaft and associated bearings are larger.

The clutch in the GPzl 100 has already seen life in the KZ1000ST shaft drive model. It is slightly smaller across than the KZ1000A chain drive clutch, but has one more plate, (nine thinner fiber plates to the 1000’s eight thicker fiber plates). On the GPzllOO, the clutch actuating pushrod bears against a ball-bearing pusher instead of the plain pusher used on the KZ1000. The KZ1000 pusher can seize if heavy-duty racing springs are installed in the clutch, or if the clutch is held in during a stop from high speed (typically, as when cutting the ignition and pulling in the clutch on the straightaway of a race course, to read sparkplug color for jetting information). The GPzllOO pusher should be more reliable.

The clutch assembly mounting is changed on the GPzllOO so that the clutch basket can be removed without splitting the crankcases first.

Those crankcases have been changed to accommodate the larger transmission countershaft and the different shift drum bearings, and to eliminate the kick starter assembly. They’re also different in that the GPzllOO has three engine mounting points; two rubber mounts at the front of the cases and one rigid mount at the rear of the cases. Fitting rubber mounts at the front of the engine reduces vibration reaching the handlebars. Kawasaki engineers found that using a third rubber mount at the rear made the GPz 1100 even smoother, but reduced rigidity in the critical swing arm area, harming handling and decreasing chain life.

The engineers tested the combination of rubber and rigid mounts on racebikes entered in 1980 World Championship endurance races, liked the results, and decided to include the concept in the 1981 GPzllOO.

Perhaps the GPzl 100’s most intriguing system is the Electronic Fuel Injection. EFI offers better throttle response and rideability than carburetors while still meeting EPA emissions requirements. The marketing advantage is that Fuel Injection carries an aura of more power, an image of High Performance. That image fits Kawasaki’s plans for the GPzllOO perfectly.

The Kawasaki EFI system, manufactured by Japan Precision Electronics under license by Bosch, was described in detail in our test of the 1980 KZ1000G-1 Classic (Cycle World September, 1980). Basically, the system has sensors to monitor ambient air temperature, engine temperature, air flow through the air cleaner, engine rpm and intake manifold vacuum. The information is fed into a micro-computer which controls when and how long the injectors spray fuel into the intake manifolds.

The EFI system used in the GPzl 100 is slightly more compact and lighter than the 1980 system. It has a less restrictive air cleaner (oiled foam vs. paper), a larger air intake, a bigger flow meter, and an enlarged air box to handle the larger engine’s increased intake capacity; a lighter fuel pump; and a smaller control unit. The GPzl 100’s control box is located in the tail section, while the KZlOOOG’s box is located in a cavity underneath the passenger portion of the seat.

Traditional riders have questioned the need for a complex injection system and have worried about not being able to make roadside repairs if something goes wrong in the electronics. Before introducing EFI on the 1980 KZ1000G, Kawasaki engineers visited Datsun (which uses the same system on some models) and asked about reliability and warranty problems. The engineers were satisfied with what they heard, which was that the system is proven and reliable. It can actually be argued that the system simplifies maintenance and has fewer moving parts.

Fuel injection has technical advantages. The system can compensate for differences in engine temperature, making a juststarted, stone-cold engine run like it’s already warmed up, with no waiting.

EFI can also increase low rpm torque, since the fuel is injected rather than pulled out of a main jet by a stream of air passing over that jet. At very low engine speeds, there often isn’t enough air velocity across a main jet to suck out enough gasoline for good power and the mixture reaching the cylinders is very lean. The injection system senses engine load and air intake and injects the proper amount of fuel, period.

Like the engine, the GPzl 100 chassis has its roots in the KZ1000. The general cradle layout is the same, but the 1100 has more raíce (29° vs. 26°) and more trail (4.72 vs. 3.43 in.) The backbone tubes are larger o.d. with thinner walls, to gain strength without gaining weight. Short reinforcing tubes link the main backbone tube with the side backbone tubes, just like tuners do on Kawasakis modified for Superbike racing, and the side backbone tubes curve down to mount low on the steering head instead of curving up to mount high on the steering head. The area where the frame downtubes meet the steering head is heavily gusseted, as is the point where the backbone tubes meet the rear frame section. The swing arm pivot mount is made of thicker plate, and tubes have been added between the two front downtubes adjacent to each rubber engine mount. The rubber mounts prevent the crankcases from tying the downtubes together effectively, and the brace tubes regain the needed frame rigidity.

The steering stem rides in tapered roller bearings, while the swing arm uses needle rollers. Front fork stanchion tube size is increased from 36mm to 38mm, but wall thickness is reduced from 5mm to 4mm. The idea is to make the forks more rigid without gaining excess weight.

Weight earned a lot of attention from the engineers. Removing the kickstarter and changing to a porkchop crank accounted for about 12 lb. less weight, compared with the KZ1000, and another 8 lb has been pared off the chassis.

The weight reduction was accomplished by the obvious—such as substituting a plastic seat pan for the steel seat base used previously—and the subtle—like the use of smaller and lighter disc rotors. Here, the GPzl 100 benefited from engineering skill applied to making the 1980 KZ750 the lightest Four in its class. Similar smaller brake discs in fact were first seen on the KZ750. So was the front> wheel, which features a small, bearingholding hub inside another, larger hub to which to the disc rotors bolt directly, without needing the usual carriers. The calipers, also from the KZ750, are carefully shaped to follow the contours of their internal parts. As previously noted, several components of the Kawasaki EFI system were made smaller and lighter before installation on the GPzl 100.

The desire to save weight could explain why the 1100’s front forks lack the damping adjustability of the Suzuki GS1100. The Kawasaki’s forks are fitted with nonlinked air caps, recommended static pressure ranging from 4.27 psi to 7.10 psi, the higher pressure specified for faster and harder riding. The rear shocks are adjustable with the usual spring preload settings and also with five damping positions. By rotating the shock spring cover, damping force can be changed a total of 53 percent in approximately 10 percent increments.

A more likely explanation for the 1100’s non-adjustable fork damping is that the bike is, above all, a sports machine and sport machines don’t need touring damping, not even touring damping that can be exchanged for sports damping at the flick of a wrist. All the effort to save weight and boost power has not clouded the GPzl 100’s intent one bit. Nothing has been given away to lure sales from the uncommitted, the less-than-deadly-serious enthusiast.

The GpzllOO comes with proper low handlebars and rearset footpegs, a seating position useful for leaning into the wind at the kind of speeds that make police radar units smoke and defense attorneys wince.

It looks the part as well. Pull into a gas station where a GS1100 owner is filling up. As the guy pumps gas into his bike’s tank he’s looking across the drive at the big red Kawasaki, reading the GPzllOO on the sidecover with a slow, dawning realization of what he is seeing. The expression on his face changes and hardens slightly. The look on his face goes way back into human history. It’s the same expression one cave man used when he saw another cave man drinking at his watering hole. Not only drinking at his watering hole, but carrying the very first bow and arrow over his back.

Riding out the driveway and up the freeway on-ramp the rider feels for all the world like Lawson heading out pit row. The barking exhaust note, the no-compromise bars and pegs, firm suspension and seat—everything is there. Even the paint is race bike.

No bike has better throttle response. Turn the twist grip and the engine rpmrises instantly. Keep the gas on and the bike picks up speed at an amazing rate, and the sensation of top speed is unrivaled by any other stock street bike. The Kawasaki easily and quickly reaches its 8500-rpm redline in fifth gear, and the bike went 135 mph in our half-mile top^ speed test.

Before the GPzllOO, the Suzuki GS1000 was the standard of high performance for street machines, so it’s natural to wonder how the Kawasaki compares.

The two machines are geared almost identically, and are perfectly matched in a1 top-gear roll-on from 60 mph to as high a speed as the rider can stand. But the Kawasaki annihilates the Suzuki in a roll-on from 3000-3500 rpm. The GPzl 100 leaps forward and goes while the Suzuki stumbles through a carburetion flat spot. At those speeds the Kawasaki shows the ad-* vantage of fuel injection.

Fuel injection also allows the Kawasaki to run quite happily through city traffic in fifth gear, at 2000 rpm, holding a steady speed without surge or buck, accelerating from that rpm easily, without demanding a gear change or care with the A twist grip. The ability to run so well at such low rpm is a direct route to high mpg.

The engine can’t be killed with the throttle, no matter if the bike has just been started after a freezing night sitting outside or if the bike has just been stopped after 20 blazing laps at a roadrace course.

At the dragstrip the Kawasaki turned 11.18 at 119.10 mph, quicker and faster4 than the 11.39 sec. at 118.42 turned by the GS 1100 we tested in April, 1980. And like the Suzuki, the new Kawasaki has enough power to fry its clutch after a half dozen banzai passes. Also like the Suzuki, the Kawasaki’s clutch holds up fine on the street or road race circuit.

The transmission shifts well, too, except when the engine is still cold. Then, while throttle response is perfect, shifting is notchy (due to clutch drag) until the engine oil reaches normal temperature.

Despite its rubber mounts, the Kawasaki does not have a smoothness advantage at the most common highway speeds. At 60 or 65 mph, the handlebars and rider pegs vibrate, although not nearly as much as the buzzing passenger pegs. Rearview mirrors remain surprisingly clear, however, and at 70 mph (about 4500 rpm) the bike is glass smooth. It’s at that engine speed that the rubber mounts most effec-A tively deal with the vibration. The density of the rubber used in the mounts determines what vibration frequencies are absorbed, and which frequencies are transmitted. So it is possible that a different density rubber could move the point of maximum smoothest to a different rpm -< range.

The 1100 has almost 2 in. more wheelbase than the KZ1000, with identical engine width and alternator cover ground clearance. Normally longer bikes require more lean angle to take a given turn at a given speed, but Kawasaki engineers have done such a job of tucking in the exhaust system and stands that it is unusual to even touch down the centerstand in hard cornering. The situation could change with sticky tires on a bike set up for Box Stock racing, but when we took the Kawasaki to the track for testing, the pegs never dragged. Racers routinely remove the stands, but even with the stands in place, the Kawasaki dragged the centerstand in only a few tight corners.

Good news for racers is a choice of front end height. The stanchion tubes stick up above the upper triple clamps about 0.75 in., which means that the forks could be repositioned lower in the clamps to raise the front end of the bike and add cornering clearance for the alternator cover, which drags on Box Stock class KZ1000 Mklls.

A certain measure of ride height adjustability is also afforded by the air forks, which will accept pressures up to 35 psi.

The rest of the Kawasaki’s handling will allow the rider to make full use of the available cornering clearance. The bike feels shorter than it is and turns quickly. The cornering agility may be due to the 3.25V-19 front tire, a size smaller than the 3.50V-19 used on the GS1100 Suzuki.

In extremely slow corners like a tight 10-mph mountain turn, the bike wants to turn in like other big motorcycles. As the pace picks up on twisty canyon roads, the GPzllOO has a steering quickness and precision characteristic of other new generation Kawasakis, the KZ750 and KZ550. Riding at the limit is where the Kawasaki shines. It is exceptionally stable, following a straight line when accelerating over bumpy sections that have other bikes attempting tank slappers. The Kawasaki even ran straight and true through sweeping Turn Eight at Willow Springs Raceway, a hand-on-the-gas top-gear curve with a dip in the middle that quickly sorts out the stable from the unstable.

Where the big Kawasaki’s performance needs improvement is in braking. Which is not to say the brakes aren’t strong enough to slow the given mass from the speeds it can attain. The problem is control, not power, as first seen at the racetrack when a test rider applied the front brakes at the end of the straightaway and instantly found himself sliding down the track. He wasn’t injured, but the bike was seriously damaged.

Next, the same rider was riding a second, replacement GPzllOO home on the freeway when a car pulled out in front of him, leaving room enough for what should have been a safe, controlled stop. Instead, the front wheel locked up at 60 mph. The rider released the brakes and steered around the car instead of stopping.

During our normal braking tests the Kawasaki’s braking features became more clear. These brakes are essentially the same as those on the Kawasaki KZ750. They are light and powerful and don’t provide the same amount of feedback as other brakes, but work well enough on the lighter 750. Only the 1100 weighs a bunch more and needs better brakes because it goes faster too. So the 1100 has brake pads with a different metallic compound, and that different compound gives more stop for the same amount of lever pressure. So far, so good.

But the amount of braking power provided per unit of lever travel with the 1100’s pads is more than our test riders liked for best stopping. With only two fingers on the lever the front tire can be locked at any speed—without gripping hard. >

That’s the beginning of the problem. At the end of the drag strip where we do all the braking tests the 1100 required 36 ft. to stop from 30 mph and 149 ft. to stop from 60 mph, not exceptionally good figures and longer than the GS1100’s 34 and 137 ft.

At low speeds the front tire would slew from side to side just before breaking loose, while the rear tire was reasonably controllable. At higher speeds the front end of the motorcycle would jackhammer, bouncing the front wheel off the ground, which caused the tire to lock.

Stopping distances increased markedly in successive stops as the brakes got hotter, grabbier and harder to control.

The GPzl 100s we rode were pilot production models, which means that they were built out of production parts alongside the production line. Full, on-the-line production of GPzl 100s was slated to begin two months after our testing.

We notified Kawasaki of the problems we encountered with the 1100’s brake system. The factory engineers telexed back that they would investigate the problems and consider changes in pad compound, lever ratio and caliper and master cylinder piston sizes. We will report any such changes.

Since it is a single-purpose sport bike, the GPzl 100 isn’t the most comfortable machine on long, straight highway stretches encountered en route to twisty roads. The seat is firm, not plush, and the suspension can’t be bothered with absorbing every little bump and concrete expansion joint. In fairness, the shocks, set on minimum preload and minimum damping, do a fair job on the highway. But that doesn’t make the Kawasaki’s ride comfortable, because the forks, even with the minimum recommended air pressure, are still sport-bike-stiff. Even with zero air pressure in the forks, the Kawasaki cannot rival a GSI 100 for riding comfort. But riders interested in plush cruising are directed across the showroom to the KZ1100A, the carbureted touring model with shaft drive and attention to creature comforts.

The details are mostly right. The quartz halogen headlight penetrates deeply into the night on high beam and splashes the roadway with an odd, squarish pattern of brilliant light on low beam. It’s a good headlight. The front turn signals double as running lights, and the taillight appears a silvery-black when the bike is at rest and the normal bright red when the engine and lights are turned on.

If one headlight beam burns out, the bike automatically switches to the other beam and a warning light in the instrument cluster comes on.

The instruments themselves are located in a large pod in front of the bars, and are electrical, not mechanical. Instead of a tach cable turning the tach needle, rpm is sensed from ignition pulses and the information delivered to the electronic tach by wire. It’s the same with the speedometer—a sender unit on the front wheel converts rotation into electrical pulses and sends the information to the speedo through a wire.

The electric odometer and resettable trip meter are positioned over the upper triple clamp, behind the instrument pod, where the odometer is impossible to see when riding the bike.

Among the instruments is a fuel gauge. The gauge needle doesn’t move away from the Full position until the bike is ridden 50-60 mi. The needle still indicated half full when the tank was empty.

Kawasaki is proud of what it calls its anti-hotwire system. Critical electrical junctions and fuses cannot be reached unless the locked seat is raised, which requires a key, at least in theory. The problem is that the seat lock is secured by one bolt (easily removed with a socket wrench) and one screw, easily forced out of its bracket with a large screwdriver. With the seat off, moving a fuse between the main power fuse holders and the taillight fuse holders yields full power to all systems.

At press time Kawasaki was still working out the GPz’ suggested retail price. But because last year’s EFI Classic listed at $4200 and inflation keeps, er, going up, we’d guess the GPz will carry a sticker close to $4500.

Those are, admittedly details. They don’t change the basic facts, the numbers, the sensations.

We have seen motorcycles with numbers before.

But we have never seen a motorcycle that matched numbers with sensations the way the Kawasaki GPzl 100 does. We’ve never seen a motorcycle this fast and this quick be so completely dedicated to sport riding. ga

KAWASAKI GPZ1100

View Full Issue

View Full Issue