SERVICE

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your "Service" letters to technical subjects only, and keep them as brief as possible. Send them to. "Service," CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

BMW SEAL

I ride a 1974 BMW R90/6 which started leaking engine oil from the bottom of the flywheel housing shortly after it passed the 20,000 mi. mark. Replacing the rear oil seal on the crankshaft and the O-ring on the oil pump cover (complete with gasket sealer on the perimeter of the cover and Loctite on the screws) solved the problem for approximately 1000 mi. at which point the engine started leaking oil again.

The engine is completely stock except that Brown Motor Works lightened the ¿lywheel when the seal was replaced. I use Castrol GTX 20W50, change oil every 1500 mi. or so, and never rev the engine above 4500 rpm.

I’ve noticed that approximately 75 percent of the 25 or so /6 and /7 BMWs I’ve examined in the last year are also leaking oil from this location. Is this normal? If not, how can I solve the problem?

Paul Royalty San Diego, Calif.

The rear seal leak was relatively common on the 900 BMWs, partly because the large twin didn’t have quite enough breather capacity to equalize pressure in the crankcase, a problem which has been fixed on the RIOOs with a better breather system. Poor crankcase breathing, however, normally causes rear seal leaks only when the engine is run at high rpms for extended periods of time. The rear crank-> shaft seal, when worn, will also leak oil even when the bike is run at lower rpm, which is probably the case with your bike.

BMW has revised and upgraded the seal, and installation of the later seal usually controls the oil problem. If it doesn’t, there are a couple of things worth checking. First, the seal rides on the surface of the inner flywheel flange, and if this surface is rough or irregular in any way the seal will wear out quickly and leak. It’s a good idea when replacing the seal to put the flywheel in a lathe and polish the sealing area to a mirror finish. With that done, another trick is to remove the circular spring from the seal, clip off about 5 mm of spring and refasten it in the seal, creating a tighter fit around the sealing surface.

The BMW flywheel is balanced at the factory as a unit with the crank, so it’s also important when removing it to mark its position relative to the crank and make sure it goes back on in the same spot. Any imbalance can create vibration at the end of the crank which is hard on the seal and the bearings. If your flywheel was lightened, however, it has presumably been accurately rebalanced.

KZ SWING ARM LUBE

One of the changes in the 1981 Kawasaki KZ550 was elimination of the grease fitting on the swing arm. The lubrication interval is the same for the 1980 model (6000 mi.), but greasing the swing arm bearings is now a major undertaking. Can the lubrication interval safely be extended to two years, the same as for the steering head bearings? If a grease fitting is installed on the swing arm. can the needle bearings on the 1981 model be adequately lubricated this way? Why was the fitting eliminated on the 1981 model?

Nicholas Carrera Falls Church, Va.

Kawasaki offers no technical explanation for the missing grease fitting, so it may just be the result of a small cost-cutting move. The design of the swing arm and needle bearings has not changed, however, nor has the recommended maintenance interval. So the first time you remove the swing arm and bearings for greasing it would probably be worthwhile to drill and tap the swing arm and install a zirk fitting where the earlier KZs have one. The only theoretical advantage to disassembling the swing arm for maintenance is that you have a chance to cheek the swing arm sleeve and bearings for wear (service limit is 21.96 mm on the sleeve’s bearing surface) and to clean them thoroughly. In practice, of course, you have to be very careful not to get new dirt in the>

bearings during reassembly, and using a zirk fitting regularly will usually push old grease, moisture, dirt, etc. out of the bearings anyway.

Unless you are riding on unusually rough or dusty roads, you should be able to go two years without severe swing arm wear or safety problems, as well-packed needle bearings keep themselves lubricated a lot better than the old bushingstyle swing arms did. When you finally service the bearings, however, check them for wear. If they are marginal or beyond service limits, the most you ’ll be out is a set of needle bearings and a sleeve.

ALTITUDE CHANGE

I have a 1979 750LN Suzuki. I bought the bike new when I was living in Wyoming. The bike ran great. When I moved to North Dakota (lower altitude) it still ran away from other 750s but it would pop and bang a lot, so I had a local shop rejet it. When I got it back it ran too rich, so I had them rejet it a little leaner. The bike still doesn’t run as it did when I first bought it, and now the No. Three cylinder goes dead occasionally. It seems to have good spark, it’s getting fuel and the compression is the same as that in the other cylinders. The plug on No. Three is a lot whiter than the others, which are a nice brown color. I would appreciate any help or advice.

Tom McArthur

Grand Forks, N.Dak.

If all the jets and needles are identical, as they should be, and correctly installed, it may be that the float level on the No. Three carb was disturbed during one of the jet changes. On the GS750 fuel level adjustment is made by bending a small metal tab, located between the two floats, which acts on the float needle. With the float bowl removed and the floats held against the needle in a fully seated position, measure the distance from the bottom of the float to the float bowl sealing surface on the carb body. It should be 25 to 27mm (0.984 to 1.063 in.). If it isn’t, bend the metal tab to bring it within range.

Suzuki also makes a tool to measure actual fuel level in the float bowls while the engine is idling and the bike is sitting straight and level. This tool is just a clear plastic hose and threaded nipple that screw into the bottom of the float bowl in place of the drain plug. When the tube is looped upward beside the carb body, it fills with gas to show you the fuel level. The fuel should come up to the surface between the float bowl and carb body with an allowable range of 2.5 to 3.5mm (0.098 to 0.138 in.)

CB SWING ARM BUSHINGS

I have a 1979 Honda CB650. It’s 4 great bike and I have modified it to make it better; shocks, oil cooler, tires, sprocket* headers, air fork caps and Quicksilver fairing. Now I want to replace those pias« tic wonder swing arm bushings with bronze or Teflon. I know this is an oddbalf bike and I’ve had to hunt for the accessories I’ve got, but somebody must make bushings for it. My God, it is a Honda after all!

A.J. Stern Dayton Ohio

The 1979 CB650 swing arm bushings are listed under the same Honda part number as those on the '79 CBX and* CB750F, before they changed over to needle bearings, so you should be able to use * any aftermarket bushing set that fits those two models. Ontario Motor Tech Corp., 6850 Vineland Ave, Unit 16, TV. Holly-, wood, Calif. 91605, (213) 766-710/, carries bronze alloy swing arm bushings far* the '79 750F and CBX for $20 per set.

WET TIRES

I own a Honda 900F and after a recent off-road excursion I’m looking for a set of rain tires and wheels to match. 1 understand that Dunlop K1 81 s are presently the best available. Dunlop recommends that they be installed as a set and offers only a 4.10 in. rib design. I’d mate this to a 3 inwide rim with a 5.10/3.5 tire/rim combination on the rear to maintain balance,, However, a 4.10 in front seems like too much tire. Is it? Can you suggest a better combination?

Ben Rozanski Madison, Ohio

While wider rims and tires, if chosen in the proper front/rear size balance often provide better cornering traction on a dry surface, extra width is normally a disadvantage in the wet, as the extra tread surface makes the tire more likely to aqua* plane, particularly in standing water. With good tires, like the K181 s you mention, thd stock wheels are w ide enough to handle as much tire as the bike needs; you will normally run out of cornering clearance before you run out of tire traction, even under box stock racing conditions.

The 4.10 number is a low-profile designation, which is about the normal inclnequivalent of a 3.50 tread in the “100” series tires, so you don’t have to worry about* having too much tire. Dunlop currently lists t he K181 ribbed front as a 100/90 V19TL, w hich is the metric tread equivalent^ oj a 425/85 in a low profile tire or a 4.00 in a normal 100 series tire. The ideal rim size-, for that tire is a 2.15 in., or WM3, which is what you have on the front of the 900F * The recommended rear K181 is a> 130/90V-18TL, the metric equivalen! of a 5.00 tire in the ¡00 series or a 5.10 in the low profile series. This is listed as the correct tire for a 2.50-18 in. rim, which the 900F has at the rear. A number of the newer high performance tires do very well in the rain, and the Kl81s are among them. For all around wet/dry performance the sizes listed above on your stock rims are probably the best bet.

JOHN PLAYER GEAR

I am in the process of modifying my 1975 Norton 850 Roadster as a cafe racer. My biggest problem is finding a suitable fairing, as most people are making them only for the bigger sellers, the Japanese bikes. What I’d really like is an original dual headlight fairing as used on the 1975 John Player Norton, along with that gas tank and seat combo. But if you could help me find a dealer that could supply me with a cafe fairing, seat, etc., I would appreciate it.

Alex Milne Billings, Mont.

Rickey Racer, 755 West 17th St., Costa Mesa, Calif. 92627, (714) 631-0430, carries a wide variety of cafe fairings, among them a number of double headlight models done in the John Player style. Prices on the dual headlight fairings range from $290 to $450, depending on whether you need the headlights, brackets and other trim and accessories. They can also order you all the JPN replica fiberglass through a supplier in England. 3

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUp Front

December 1981 By Allan Girdler -

Letters

LettersLetters

December 1981 -

Departments

DepartmentsCycle World Roundup

December 1981 -

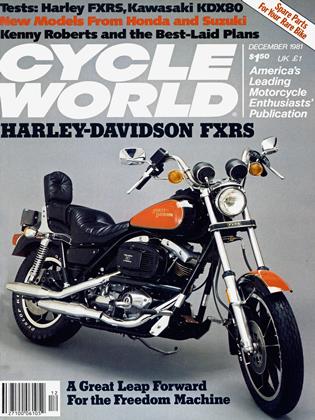

Features

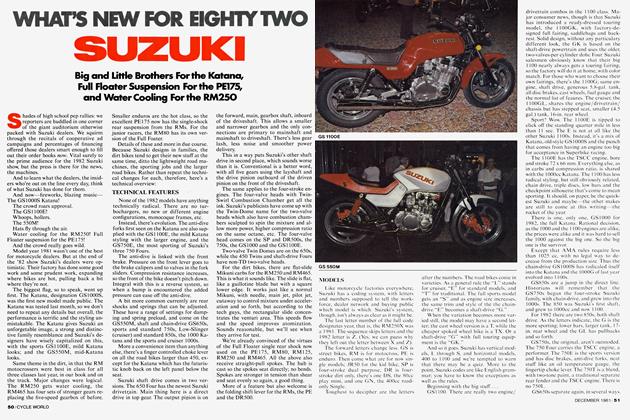

FeaturesWhat's New For Eighty Two Suzuki

December 1981 -

Departments

DepartmentsBook Reviews

December 1981 By Henry N. Manney III -

Features

FeaturesA Guide To Orphan's Homes

December 1981 By Dee Winegardner