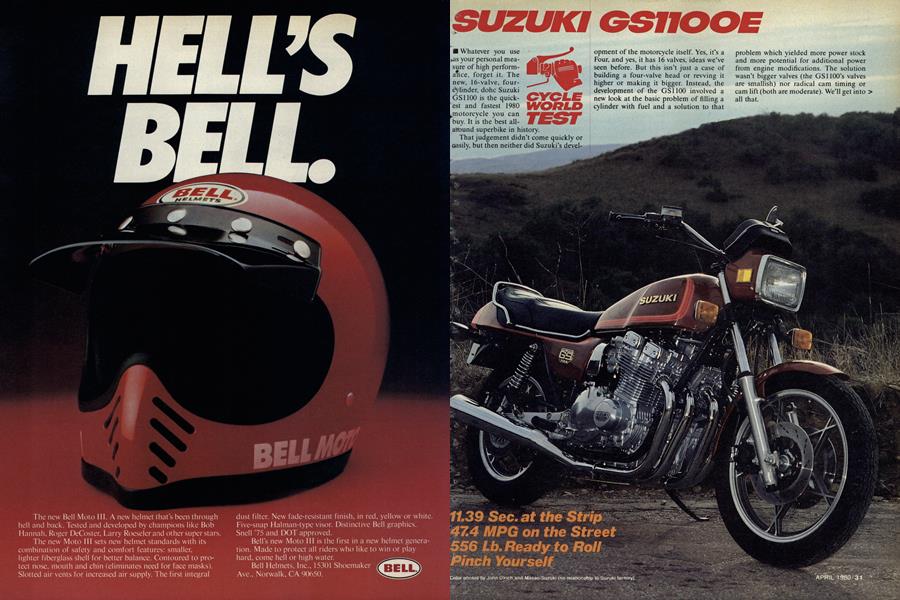

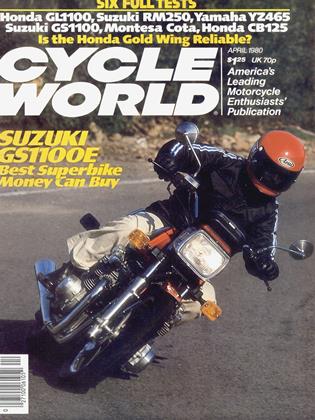

SUZUKI GS1100E

CYCLE WORLD TEST

11.39 Sec.at thes Strip 47.4 MPG on the Street 556.Lb.Ready to Roll Pinch Yourself

Whatever you use

as your personal measure of high perform-

ance, forget it. The new, 16-valve, four-

cylinder, dohc Suzuki

GS1100 is the quickest and fastest 1980 motorcycle you can buy. It is the best all-around superbike in history.

That judgement didn’t come quickly or easily, but then neither did Suzuki’s development of the motorcycle itself. Yes, it’s a Four, and yes, it has 16 valves, ideas we’ve seen before. But this isn’t just a case of building a four-valve head or revving it higher or making it bigger. Instead, the development of the GS1100 involved a new look at the basic problem of filling a cylinder with fuel and a solution to that problem which yielded more power stock and more potential for additional power from engine modifications. The solution wasn’t bigger valves (the GS1100’s valves are smallish) nor radical cam timing or cam lift (both are moderate). We’ll get into > all that.

Our investigation of this machine involved briefings with Suzuki engineers at the factory in Hammamatsu, meetings with road racing tuner Pops Yoshimura in Tokyo and an engine teardown with drag racing wizard Byron Hines in Los Angeles. We rode the GS1100 on the Suzuki test track in Japan in stunning cold and on the streets and highways of America in warm sun and freezing rain. We used the GS 1100 to ford streets flooded deep enough to wash water over the footpegs, to streak straight country roads at 140 mph, to commute 90 miles a day for weeks, to split lanes on the freeway, and, finally, to rip down the dragstrip.

Even the most skeptical are impressed with the GS1100 once they experience its function. It has power. It is comfortable. It handles well. It isn’t another 600-lb. motorcycle, instead weighing less than anything we’ve seen before in this size and performance category, 556 lb. with half a tank of fuel. It meets 1980 emissions standards. It gets good mileage, returning 47.4 mpg on the Cycle World mileage test loop.

And it’s faster than hell, turning the quarter in 11.39 sec. at 118.42 mph. Nothing else coming out of a dealer’s showroom in America can touch it.

Sadao Shirasagi is the manager of fourstroke engine development for Suzuki Motor Co., Ltd. in Japan. His work is why Suzukis are getting faster despite EPA demands.

In Shirasagi’s view, the most important thing when considering a motorcycle engine is performance, the ideal being excellent acceleration, good throttle response, low E.T. at the dragstrip and maximum power. That’s a hard goal to argue with, and few motorcyclists, given the choice, would turn down acceleration, throttle response, low E.T. and maximum power.

But unlike everybody else, it fell to Shirasagi and his team of engineers at Suzuki to actually build the engine that not only met the performance criteria but which also met the social needs of low emissions and reduced fuel consumption.

The answer, Shiragasi decided, was cylinder charging: get more fuel into the cylinder and burn it faster. The patented system he developed is called Twin Swirl Combustion Chamber (TSCC) and what it does is take advantage of turbulence.

This is not exactly a new twist, excuse the pun. The incoming charge of any internal combustion engine naturally turns, spins and gets agitated. There was an entire school of Grand Prix two-stroke development based on this and one of the few secrets Honda ever made public is that the agitation of the charge at extra-high revs speeds up flame propagation and combustion, which is why those four-stroke engines worked at speeds far higher than anybody predicted.

TSCC takes this further than anybody else has dared to go.The shape of the ports. the valve angles and the contours of the combustion chamber send the incom ing mxture into two parallel accelerating swirls rotating in the same direction as the hike's wheels spin. The swirls speed up the charge when the intake valves are open and distribute the charge evenly during corn pression.

Shiragasi sees this as the basis for a series of interconnected engineering deci sions and advantages:

• Improved charging means equal in take with relatively smaller valves. • Smaller valves mean a narrower valve angle is needed to fit the valves above a given bore.

• Smaller valves mean less masking of the valve by the combustion chamber walls, hence better flow.

• With small valves and a narrow in cluded angle. the combustion chamber can he flat and still be small enough to give a high compression ratio with a flat-top piston.

• The flat-top piston doesn't interfere with swirl and because it has less surface. less heat is drawn away from the chamber and the heat remains free to push the piston down.

• Filling the cylinder eflicientlv means that you don't need to use as much cam shaft timing; the duration, lift and overlap can all he mild. SO the engine makes power at low speed while still cranking out horses at peak.

• Faster burning means more cylinder pressure at the start of the power stroke. and less pressure when the exhaust stroke begins. SO less energy goes oUt the exhaust. Heavy stuff, and heavy theory.

Direct comparisons are difficult. There are no other 1100cc four-valve Fours. But allowing for varying cylinder sizes and designer preferences. the (iSI 100 has an included valve angle of' 40° and Honda's CBX has an angle of(3°. Viewed from the side, the Honda has a combustion cbam her peaked. a pent roof as they say, and the Suzuki has a much flatter roof a flat-top piston and a c.r. of 9.5:1, while the Honda has a domed piston and 9.3:1.

As another real-life benefit, the shallow valve angle lets the valve guides intersect the ports at a steeper angle, so less of the'. guide protrudes into the port. That helps flow, and because there's less material in the way of the exhaust gas, less heat gets transferred from the exhaust to the guide and the valve, which aids engine life.

Back with theory. when the four-valve head first made its return to production. everybody thought the secret was in creased valve area and the ability to keep smaller and lighter valves under control at high revs without excessive spring pressure. Turns out that wasn't the whole story, The performance advantage isn't valve diameter or higher redlines. Instead, the added breathing comes because the cir!' cumference of four small valves is greater than with two large valves.

Working valve area is the cylindrical shape between the edge of the valve itself' and the rim of the valve seat, at full lift. Measured this way. that is, the Suzuki's eight 27mm intake valves and eight 23mm exhaust valves vs the Honda's 12 25mm intake and 12 22mm exhaust valves, we get a total area of 4750.1mm2 intake and 3757.3mm2 exhaust for the GSI 100, and 7351.3 mm2 and 5805.7 mm2 for the CBX:' Thus, the (BX has more total valve area than the GS. (The Six also uses longer camshaft timing, although a direct comparison between a 175cc cylinder and a 268cc cylinder doesn't work.)

For the bottom line on this. Suzuki claims 105 bhp and Flonda says the 1980 CBX has 97 bhp. both measured at the countershaft sprocket. Independent dyno tests in the U.S. show more of a difference, maybe 90 bhp for the GS1100 and 75 bhp for the CBX. at the rear axle.

Closer still, the 1979 CBX went through the drag strip lights at 118 mph. the '80 CBX dropped off to 114 mph, and the GS1100 did 118, with several runs at 119. It's lighter than the CBX but even so, trap speed being a result of power to weight, the GS1100 has as much sheer power as the earlier Six and more than the '80 Honda.

The TSCC system seems to work. And the four-valve GS1100 head flows much more air than a typical two-valves-percylinder engine. For example, consider the GS1000, which has 38mm intake valves and 32mm exhaust valves, with 8mm of intake lift and 7.5mm of exhaust lift. C orn-

paring the GS1000 cylinder head with the GS1100 cylinder head on a flow bench, the heads are actually about equal in basic flow' efficiency when compared at the reference point at which valve head area equals actual valve area (the area of cylindrical shape existing between the circumference of the valve head and the circumference of the value seat).

But given equal lift, the GS1100 head is much more efficient—the four-valve head exposes more actual valve area per unit of lift.

The GS1100 also has a big advantage in terms of valve area exposed in relationship to crankshaft position. The four-valve head opens the valves more, and opens them sooner, in terms of degrees of crankshaft rotation. In fact, in order to match the flow of a stock GS1100 cylinder head with stock camshafts, a GS1000 would have to be fitted with camshafts that provided about 10mm (0.400 in.) of lift. That’s a pretty radical cam, especially considering that the stock GS1100’s intake cam provides 7mm (0.276 in.) of lift.

The significance of that comparison can easily be seen by anybody interested in hopping-up a GS1100. If a stocker equals the flow of a GS1000 with high-lift cams, imagine the flow numbers a GS1100 should produce with high-lift cams . . .

So far it all sounds pretty good, and the advantages are clear. But Shirasagi and his team of Suzuki engineers had substantial problems to deal with to make it all happen.

We’ve seen that narrow valve angle reduced guide protrusion into the ports. It’s true that the superior TSCC charging enabled the use of smaller valves, which reduced the valve angle needed to fit the valve heads, which allowed the compact, low combustion chamber needed for TSCC. But narrowing the valve angle would normally increase engine height in a dohc engine, since the cam lobes are located over buckets fitting over the valve springs and stems. The closer to vertical the valve angle, the closer the cams are to the centerline of the engine, the higher the cams ride, and the taller the engine becomes. A motorcycle engine can only be so tall before it won’t fit into a frame designed for good handling, or before it is too top heavy.

What Shirasagi did was locate the cams next to the valves and operate the valves through forked rocker arms. Each cam has four lobes, each lobe operating one set of two valves. The rocker arms pivot on shafts located underneath the camshafts, and reach up at an angle to the valve stems. The cam lobes operate against pads located between the rocker pivots and the valve stems. The hollow rocker shafts are pressurized and an orifice in each rocker sleeve squirts oil onto the cam lobes.

The concept worked in reducing cylinder head height: the GS1100 head measures 102.3mm from head surface to camshaft centerline, compared to the GSlOOO’s 105.5mm. The effect of the system on overall engine height can be seen in the fact that the GS1100 engine equals the GS1000 engine in distance from crankshaft centerline to camshaft centerline in spite of having less valve angle. 40° to the GSlOOO’s 61°; a longer stroke, 66mm compared to the GSlOOO’s 64.8mm; and longer connecting rods, 116.5mm compared to the GSlOOO’s 115.0.

In the process of solving the valve angle/ engine height problem, Shirasagi gained a couple of other advantages for the GS1100. Because rocker arms are used instead of valve buckets, the valve springs are exposed to a cooling oil mist coming off the valve train, and the oil mist increases valve spring life.

The absence of the valve buckets—and the resulting improved access of lubricating and cooling oil—is important also to counter a drawback to the rocker arm system. Because the cam lobes push on rocker pads located between the rocker pivot and the valve stem, the valve stem is loaded sideways.

The rocker system will wear the valve stems more than the bucket system. But the advantage of more lubricating oil reaching the valve stems helps offset the disadvantage of side loading. While the loading showed up as a wear line on valve stems and guides in a GS1100 engine run wide-open on a dyno with insufficient cooling air flow for large displacement engines, the situation w ill be less critical in actual street use, where increased engine speed normally results in increased cooling air flow.

Another advantage gained by not using buckets is reduced distance between valves. Shirasagi didn’t have to fit buckets and bucket bores between paired valves, sc the valves could be located closer together That put the valve heads farther from edges of the combustion chamber, reducing valve masking and contributing to increased gas flow.

Of all the advantages of the rocker arm system, Shirasagi regards easy maintenance as being the most important. The owner of a new GS1100 or GS750 won’t have to keep a supply of shims on hand to adjust his bike’s valves, and won’t have to run to the local dealership in the middle of a home tune-up to buy shims (at $3.50$5.50 each) he needs but doesn’t have. He won’t need any special tools, either, because the conventional screw-and-locknut tappets can be adjusted with a screwdriver and wrench.

A final rocker arm advantage of interest to anybody considering hopping up a GS1100 is the 1.55:1 rocker arm ratio, which means that 1mm of cam lobe produces 1.55mm of valve lift. (The old sohc Honda 750 had a rocker arm of 0.99:1). That means that the GS1100’s lift can be increased without requiring a radical cam profile. In the case of the GS1000, the physical size of the lobe needed to produce, for example, 11mm (0.420 in.) of lift forces relief of the cam cover and cylinder head cam case to clear the lobe. And rbecause the huge lobe required slams down on a flat surface (the valve bucket), lift acceleration is radical. With the Suzuki’s rocker arm system, a tuner can get increased lift with smaller cam lobes and smoother ramp action.

Like the cylinder head, the pistons found in the GS1100 are different from those found in other stock machines. To start with, the piston skirts are coated with molybdenum disulphide (MOS2), a metallic lubricant useful under high-load, highheat conditions. The GS 1100 has the same outside cylinder block width as the GS1000, and so has the same cooling fin area. Yet the GS1100 makes more power and produces more heat, so Shirasagi and his engineers use the coated pistons to prevent gauling and scoring during the critical break-in of the engine.

The top compression ring is only 0.98mm thick. A thicker ring has more cylinder contact area and weight. Inertia makes the ring want to keep traveling upward when the piston stops at TDC, and friction against the cylinder wall wants to hold the ring stationary when the piston starts down its stroke. In both cases, those forces beat the ring against the top of the piston groove, and can wear and enlarge the groove. The lighter and thinner GS1100 top piston ring reduces ring groove wear (and resultant compression loss) in high-performance use.

The second ring is a conventional 1.18mm thick, and placement of the ring grooves is conventional. In theory, a higher top ring placement results in more power, but can cause ring overheating in extended use. Compromises have to be reached when an engine will be used in rush hour traffic and not just for brief blasts down the dragstrip with cooling intervals between runs.

In prototype stages, Shirasagi used a 20mm o.d. wrist pin—bigger than the GSlOOO’s I8mm wrist pin—in anticipation of problems resulting from the GS1100’s extra power. But the 20mm wrist pin proved to be overkill. For the production GS1100, Shirasagi settled on an 18mm wrist pin treated with a hard surface coating (0.030 in. thick) which doesn’t transfer metal easily, thus resisting gauling and seizing.

According to Shirasagi, the GS1100 has a built-up, roller-bearing crankshaft (instead of a forged, plain-bearing crankshaft like the new 16-valve GS750) because that allows Suzuki to use the same case machining equipment used for the GS1000— the GS 1100 has the same crankshaft center to mainshaft center distance as the GS1000. Shirasagi says that if a forged crankshaft were used, the rearward rod bolt on the number four throw would hit the clutch basket in the course of a crankshaft revolution.

But while the GS1100 doesn’t have a forged crank, it does have improvements designed to make its crankshaft more twist-resistant than the crank used in the GS1000. The pins are larger, the crank pin measuring 31.8mm o.d. compared to the GSlOOO’s 29mm. The increase in diameter combines with wider counterweights to dramatically increase the contact area in the crank press fit.

Another difference seen when comparing the cranks from the 1100 and the 1000 is the use of a large nut to hold the alternator flywheel on the crank taper. The GS1000 uses a bolt, and once the alternator is removed (for, say, welding the crank pins to prevent twisting in a hopped-up engine) it’s just about impossible to get the bolt to keep the flywheel on the taper afterwards. The huge nut on the GS1100 threads over the crank end, a much stronger arrangement than threading a bolt into the crank end.

The GS1100 clutch is smaller than the GS1000 clutch The basket is forged instead of cast and lacks the slots seen in the GS1000 clutch basket—both changes made for greater strength. The 1100 clutch also uses nine drive plates instead of the GSlOOO’s eight.

Although the GS1100 transmission has the same ratios and general dimensions as the GS1000 transmission, it has been strengthened with changes in materials, specific gear dimensions and some design aspects. To start with, the metal used in GS1100 parts has a higher nickle content (1.8 percent vs. 0.25 percent) than the metal used in the GS1000 transmission. Adding nickle to the original siliconechrome-moly alloy increases resistance to breakage under shock loading.

Comparing the GS1100 transmission to the GS1000 transmission:

• both shafts have more oil feed holes for better lubrication of bearings and bushings

• countershaft first gear spins on a needle roller bearing instead of a bushing

• countershaft second gear has an oilfed plain bearing instead of a dimpled bushing

• mainshaft second gear is 1mm wider for more press fit contact area, with a corresponding width increase in countershaft second

• third, fourth and fifth gears on both shafts are wider by an average of 1mm

• shift fork grooves in mainshaft third and countershaft fourth have oil feed holes to reduce shift fork wear

• second gear engagement speed is increased and snatch reduced by using three peg-shaped dogs fitting into their choice of six smaller oval-shaped holes in the adjacent gear, instead of four dogs sliding into four larger holes

• fifth gear is engaged by three smaller dogs sliding between six smaller dogs instead of four dogs sliding between four larger dogs, again reducing engagement time and snatch

• fourth gear is engaged by three pegtype dogs fitting into a choice of six elongated holes instead of three larger, squareedged dogs engaging three other square dogs, lowering machining costs and reducing engagement time and snatch.

Unlike previous GS models, the GS 1100 has forward-facing spouts on the sump oil pickup to ensure that oil pressure is maintained under hard braking. But because the pickups are pointed forward, the oil pressure warning light comes on under very hard acceleration in lower gears, which means that the force of acceleration pushes the oil to the rear of the sump, away from the pickup. Suzuki engineers may have settled on the forward-facing pickups because a rider is more likely to use the brakes hard in normal riding than to accelerate at full throttle in the lower gears. The important thing is that despite the oil pressure warning light flickering under extreme acceleration, the engine isn’t harmed. Roller-bearing crankshaft engines use relatively low oil pressure, and losing that pressure momentarily doesn’t result in bearing damage as it can with a plain bearing crankshaft.

Fitting an oil cooler to the GS1100 engine is easy. Unscrewing a pair of plugs—one located on each side of the oil filter cover at the front of the crankcases— allows direct access into the oil galleries. Once a passageway behind the filter cover is blocked off and cooler lines installed, all the engine oil is routed to the oil cooler and then through the filter. For convenience, the crankcase castings are even marked “in” above one plug and “out” above the other.

For all the extra technology and strength built into the GS1100 engine, it isn’t overweight or overly wide. In fact, the dry GS1100 engine weighs 193.8 lb., and measures 22.6 in. wide. That isn’t much more than the GS1000 engine, which weighs 180.2 lb. and measures 22.5 in. at its widest point.

Like all the 1980 GS models, the GS1100 comes with Suzuki’s maintenance-free pointless electronic ignition and Mikuni CV (constant velocity) carburetors. The switch to the electronic ignition means that the bike’s owner won’t have to adjust points or set timing, but the improved performance of such an ignition in extended emissions tests was another factor in its use. It’s possible to build a bike with contact breaker points that will pass the test, but to compensate for rubbing block wear and contact point deterioration the bike must be set up farther on the safe (lean) side in carburetion, which affects driveability.

Then, too, EPA emissions requirements influenced the decision to use the CV carbs. It’s true that the CV Mikuni carburetors improve cold starting and yield higher gas mileage, but Shirasagi says that the most important consideration is the fact that CV carburetors perform better in low-speed EPA hydrocarbon emissions tests. The carbs on the GS1100 are nominally 34mm but are the equivalent of a 30.4mm slide-throttle carb. If hydrocarbon emissions were not restricted, and if equivalent size slide-throttle carburetors were used (i.e., 30mm), then, Shirasagi says, the GS1100 engine would make more power.

The GS1100’s exhaust system weighs more than the GS1000 system, 37.9 lb. to 35.1 lb. The gain comes from a new crossover tube joining the number two and three exhaust pipes underneath the engine. Because the number one and number two pipes join before one muffler and the number three and number four pipes exhaust into the other muffler, the connection in effect balances the entire exhaust system.

While the GS1100 frame has the same configuration as the well-proven GS1000 frame, and although both frames are made of the same material and use the same tube diameters and thicknesses, there are slight chassis differences.

Remember the ease with which oil cooler connections could be made to the engine? Mounting the cooler will be just as easy, because the GS1100 frame has a threaded mount positioned high on the front of each downtube and a third centered in bracing below the steering head. The mounts could be used to hold the top of an engine guard (or crash bar) as well, because extra bolt tubes are provided near the front engine mounts, positioned to fit a case guard’s lower lugs.

Steering head angle is the same as the original GS1000, 28°, but less than the 29° head angle found on the GS1000L semichopper, which has leading-axle forks similar to those found on the GS1100. (The GS1000 has center-axle forks). The GS1100 has less trail than the GS1000 models, 4.06 in. compared to 4.4 in. for both the standard GS1000 and the GS1000L.

The most noticeable GS1100 frame change is the use of a box-section aluminum swing arm, which at 20.5 in. is the same length as the GSlOOO’s tubular steel swing arm, but which weighs just 7.05 lb. to the GSlOOO’s 9.9 lb.

Suzuki lists the GS1100’s wheelbase as being 59.8 in., or 1.1 in. longer than the original GS 1000’s 58.7 in. wheelbase. That difference can be accounted for in the GS1100’s long-travel, leading-axle fork— the axle is held about 1 in. ahead of the fork centerline. (Our test GS1100’s wheelbase measured out at an actual 60.5 in., but the extra length came from the positioning of the rear axle by the chain adjustors.)

More important than where the forks hold the front axle is the number of adjustments that can be made to them. In combination with the Kayaba rear shocks— which have five spring preload positions and four damping adjustments, and which debuted on the original GS1000—the GS1100’s forks give it the most adjustable suspension ever seen on the street.

To start with, the forks are air-assisted Rayabas with 6.3 in. of travel, rated for 7.1 psi in each leg. Checking air pressure is simple: air enters each leg through an orifice located just above the lower triple clamps on the front of the fork stanchion tubes, an orifice sealed by a needle-andseat stopper valve. One tube connects the stopper valves to the filler valve. When the stopper valves are opened, the fork tubes can be filled simultaneously through the filler valve. With this system, pressure in the fork legs is automatically balanced, and if one leg loses its air, the other leg isn’t affected.

But although adjusting pressure is easy, Suzuki engineers are adamant that the pressure must not be varied from the specificed 7.1 psi. Fork spring rates were calculated for use with 7.1 psi, and the engineers built a four-position spring preload adjustor cam into the top of each fork leg (that’s why the GS1100 uses air valves on the tubes, and not air caps).

The goal, according to Suzuki engineers, is to maintain a constant amount of fork travel regardless of spring preload. The GS 1000 has air forks, hut with that system, when air pressure is increased to raise ride height or stiffen the springing, fork travel is reduced. With the GS1100 system of constant air pressure and adjustable spring preload, fork travel does not vary, so the rider gets full benefit of the long travel.

In theory, adjusting fork spring preload should be easy, because the cam adjustor can be turned with a straight-blade screwdriver after rubber dust caps are removed. In practice, it isn’t that simple. The bike must be on the center stand, with either another person holding the rear end (to lift the front wheel) or with a block under the engine cases. The handlebars block a straight approach to the cam adjustor screwdriver slots, so a relatively thinbladed screwdriver must be inserted from an angle, pushed down hard, and rotated. It’s easy to mess up the screw slot in making adjustments, and changing preload on the road without another person or a block to use as an engine jack is impossible. An offset screwdriver would make reaching the slot easier, but wouldn’t allow pushing down the adjustor cam while turning—and without downward pressure, the cam won't turn.

But as inconvenient as adjusting the preload can be. the final adjustment available—that of compression and rebound damping—is supremely easy. All it takes to select one of four damping positions is turning a large knob on the bottom of each fork slider. The knob is directly connected to a tube inside the damper rods, and rotating the inner tube (via the knob) determines the size of an auxiliary oil bleed hole, and thus, damping force. Position one has the largest hole (for the softest ride), while position four has the smallest opening. The knob has numbers on its circumference and each setting clicks into position.

Suzuki engineers say that the slots in the GS1100’s brake discs don’t do anything but improve looks. The brake pads have a higher metal content than before, the engineers add, to improve wet weather braking, and the GS1100’s brakes are the best available, wet or dry. The slots may aid heat dissipation, but do nothing to make the bike stop quicker in the rain.

But our test bike with slotted discs showed no disc scoring in thousands of hard miles, something that always appeared on previous GS brakes. We believe that the slots remove grit and small stones from the pad surface, preventing the grit from becoming caught between pad and disc surfaces and thus preventing scoring.

The engineers we talked to wouldn't go so far as to admit that the slots remove grit, but they did say that grooves cut in racebike disc rotors will remove pad oxidation (burn or glaze) caused by heavy braking.

Mr. H. Morikawa is Suzuki’s manager of the Body Design Dept, and as such styled the GS1100. According to Morikawa. Suzuki sent stylists to the United States to survey the motorcycle market. Whatever they saw led to the prototype styling of the GS1100. a style which, when seen by selected American and European Suzuki representatives, was labeled as being too radical. In the words of Morikawa, the first design was too advanced for the market.

With those findings, Morikawa backed off the futurism a notch for the second prototype, which became the production design.

(“It looks pretty nice.” said one rider we met in front of a liquor store, “but did they have to make it look so futuristic?” Other comments heard on the street ranged from extreme dislike “That’s the ugliest motorcycle ever made!” to love at first sight “I think it looks great!” Since styling is a matter of personal taste and since you can look at the photos and decide for yourself, we’ll decline to comment. Let us just say that the GS1100 has enough horsepower "that many riders won’t care how' it looks.)

Morikawa considers the current design out of balance, but looks to the future when he thinks that the market will accept a more integrated, streamlined style.

In the meantime, Morikawa liked the impact of the leading-axle front forks, rwhich he feels look more powerful or forceful than center-axle forks. One problem Morikawa faced was visually reducing the size of the motorcycle because performance motorcycles aren’t supposed to be tanks. One approach was to sharpen the bend of the head pipes at the front of the ^engine (for a more compact exhaust system), making the bike look smaller. Because design steps were taken to heighten the performance look, Morikawa felt that there must be balance. Some people are afraid of high performance, thinking it to be dangerous, says Morikawa, so he included a check panel in the instrument cluster—to express safety.

The check panel positions five small red warning lights on a motorcycle diagram. One light indicates that the headlight is burned out, while another warns if the taillight is out and another monitors the brake light. The two remaining lights warn if rear brake fluid or battery water levels are low'.

That check panel is the first thing to catch your eye as you climb aboard the GS1100. The instruments are built into a plastic housing attached to the headlight, and include a speedometer, tach. separate odometer and push-button-reset tripmeter set in below the speedometer, a fuel gauge and, of course, the check panel.

Like the GS750, the GS1100 has no reserve setting on the fuel petcock, so the rider must rely on the fuel gauge, which seems fairly accurate—about 100 miles of riding puts the gauge needle at the halfway mark.

Accurate or not. not one member of the staff, no matter what his age or background, liked or trusted the gauge and noreserve petcock. In fact, we hate it. Even with NASA accuracy, no dratted dial can take the place of knowing just how much fuel is in the tank, or of being able to physically remind yourself that it’s time to top up.

The instruments glow a soft red at night.

and for the most part are easy to read. But the odometer and tripmeter lighting, while better than that on our recently-tested GS750, wasn’t good enough. The rectangular quartz-halogen headlight is the best in motorcycle lighting when it’s properly adjusted. Because it is rectangular and mounted in a huge plastic housing, the healight can’t be adjusted en route like a round headlight held by traditional ears. The rider must get off the bike and work with a screwdriver to alter the beam position. When incorrectly adjusted (the light on our test bike wasn’t even close when delivered), the headlight doesn’t do much more than blind oncoming drivers even on low' beam.

The turn signals are self-cancelling but the turn signal swatch and its action are both odd. Moving the sw'itch left or right activates the turn signals, while pushing the switch straight up or straight down selects high beam or low beam. Because the switch is farther from the left edge of the control module than a traditional high/low switch, the rider must reach farther with his thumb to work it.

And w;hen reaching for the turn signals, it feels like the switch has five positions, with 1 and 5 activating the signals and 3 being the center (off) position. When the switch is pushed to position 2 or 4. it feels like the blinkers should work, as if Suzuki engineers wanted to include a snap-back lane-change mode. Yet nothing happens^ until the switch clicks into position 1 or 5.

Specifications overleaf, text continued on page 156

SUZUKI

GS1100E

$3669

continued from page 39

Then, when the signals cancel themselves following a turn, the switch returns not to the center, but to the 2 or 4 position, depending upon whether a left or right signal was made. The next time the rider 41 goes for the switch when making a turn in^ the opposite direction, he’s apt to move the switch back to center and not activate the signals.

Like other GS Suzukis, the 1100 has a starter interlock—the electric starter won’t turn over the engine unless the clutch is pulled in. And like the rest of Suzuki street bikes, the GS1100 has simply awful grips. «

But the hollow-stem mirrors (mounted in rubber for good measure) are clear at all speeds. And overall the GS1100 is very comfortable with an excellent seat. It does vibrate more than the GS750 (buzzing the < grips much like a GSIOOO does), and we didn’t care for the bar/seat/pegs relation-# ship, but changing the handlebars isn’t a major operation (as it is on the Honda CBX, requiring loosening the engine mounts and lowering the engine). The pegs seem high because they are, 12.5 in. off the ground compared to the GSlOOO’s 11.9 in., to help compensate for the^ GS1100’s longer wheelbase. (A longer wheelbase bike needs more lean angle to negotiate a given turn at a given speed, all other things being equal. If two bikes have equal cornering clearance but one has a longer wheelbase, it will have a lower maximum cornering speed, again, all other things such as tires being equal."

Suspension can determine how well motorcycle goes around a corner and also , how comfortable it is. The GS1 lOO’s forks and shocks work for everything from« straight-line cruising to high-speed tearing, depending upon the setting. *

At the Suzuki test track in Japan, the ’ GS1100 was terrible, wobbling in sweeping turns, pogoing and jumping around1 when accelerated hard off turn apexes, ] grinding parts against the asphalt in mid i turn. This thing is another GS750, the ! rider thought, under sprung and under ^ damped with severe ground clearance ■ problems. About all it did right was run steady, stable and true on the1 straightaways.

Back in the pits, we found that the forks were set with position #2 damping and # 1 spring preload, while the shocks were at # 1 preload and # 1 damping.

We complained, and the factory mechanics consulted their little black tuning* specification books before making adjustments. They settled on forks at #3 damping and #3 preload, shocks at #5 preload and #3 damping.

It made a big difference. The wobble in sweeping turns was gone, along with the pogoing and jumping around off the apex k of tighter turns. As lap times came down, the rear end started chattering, and the GS1100 still had traces of a strange response characteristic it shares with the GS750—in the momentary transition between upright and leaned over for a turn, it feels like the rear end is stepping out,

► although it isn’t. The response characteristic may be a function of the GS1100’s relatively short trail, which tends to quicken steering and maintain agility despite a stability-increasing, longer wheelbase. The rear end chatter could be caused by the 4.50V-17 Bridgestone rear tire, which also drifts and slides more than, say, a Metzeler when accelerating off a turn.

The brakes worked very well, being predictable and powerful, but the front end Move more under braking than the GS1000. That’s because the GS1100 has the same 6.3 in. of travel regardless of the fork settings, while pumping up the air pressure in the GS1000 reduces available travel, and thus, dive.

Even with the shock and fork preload ♦.turned up, the GS1100 still dragged parts in corners, starting with the centerstand and pegs on both sides and followed by the sidestand and sidestand bracket on the left K and exhaust system parts on the right. Once you’ve got the GS1100 leaned over far enough to drag the sidestand bracket, it could mean trouble, since any more lean (or even a bump on your line) can lift one yor both wheels and put you on your head. But if you can do that on the street, you’re

► either crazy or not hanging off enough, or both. On the racetrack, providing that the

► pilot knows how to transfer a lot of body weight to the inside, the GS1100 can be

. ridden around very quickly. It may be that va GS1100 cannot be flung around a tight turn as quickly as a GS1000 since the GS1100 has the longer wheelbase discussed earlier. But even if the 1100 can’t t match the 1000 mid-turn it will trample it powering off the apex. And if the GS1100 isn’t the best handling superbike of its size, then it is at worst a close second to the *GS1000. Considering that the GS1100 is much more comfortable than a GS1000 for highway use, in essence the 1100 com* bines the best of a backroad bandit like the GS1000 and an interstate plushbucket like the XS11.

The proof came back in the United •States, on the Cycle World mileage loop. We run every test machine around two 50mile laps of the loop, which combines city h traffic, country road and interstate. Our first lap with the GS1100 was with the suspension set for canyon crusading. The bumps on the old city pavement, the cracks /and holes in the country road, the expansion joints in the concrete freeway all went straight to the rider’s body, making the Suzuki in high-performance mode as unsuited for street use as the same bike in street comfort mode is for racetrack use.

continued on page 162

continued from page 157

At the end of the first 50-mile circuit, we pulled over and reset the suspension to softest on everything—# 1 fork preload, # 1 fork damping, # 1 shock preload, # 1 shock damping.

On the next loop, the GS1100 soaked up jolts from the expansion joints and reacted instantly to small bumps. And when we turned the wick up it bottomed on potholes and big bumps and wobbled in fast, bumpy turns, just to remind us that we had dialed in maximum comfort.

The temptation is to instantly dial in either maximum or minimum on all the settings, ignoring the settings in between. Fact is, the suspension offers a lot of combinations between full soft and full hard, and it’s up to the rider to dial it in correctly to suit his riding style, weight, luggage load, etc. Do it right and it works. Using the bike for one thing with the suspension settings set for another is another matter.

Regardless of use, one constant, unchangeable fact of the GS1100 is power.

Power, for us, is what the GS1100 is all about. And it has it.

Not just the kind of power and top speed that works neck muscles fighting wind pressure or makes it difficult to move your left hand from stanchion tube to left grip as you come out of a tuck at the end of the straightaway. The GS1100 also has the kind of power that makes the transmission unnecessary above 40 mph. Snap the throttle open in fifth gear at 3000 or 4000 rpm and the Suzuki has the torque to move right out. None of this downshifting to pass trucks on interstate uphills, no sir. Just nail the throttle, and watch the speedometer needle climb.

It’s that kind of usable power that made the GS1100 so popular around Cycle World. E.T., top speed, plus useful street lunge.

It’s a good thing that the GS1100 could pull low rpm, because if it couldn’t, then the bike would be intolerable around town.

That’s because Suzuki’s (or Mikuni’s) carburetion technology still has a long way to come compared to the Keihins found on high-performance Hondas.

True, the CV Mikunis have a lot to do with the great mileage, 47 mpg on the~ Cycle World mileage test loop, 40-45 mpg in normal, over-the-speed-limit use, (although on the racetrack in wide open use, mileage dropped to 20 mpg, no better than slide-throttle carbs).

But the carburetors are very lean just off idle and cause the bike to buck and surge in low load, low speed, small-throttleopening cruising. They’re also touchy, making it difficult under some conditions to minutely vary the bike’s speed.

True, after testing the GS550, GS750 and GS1100 all in quick succession, we quickly learned to ride around the charac, teristic, by shifting up a gear or two and riding at 35 or 40 mph in top gear. The GS1100 doesn’t buck when the engine is loaded by running a higher-than-normal gear, and riding to accommodate the carbs isn’t as difficult as it sounds.

Two conditions had the GS1100 at its lean-carburetion worst: riding at 35 mph in third gear, and sloshing 50 miles down the interstate at 60 mph in pouring, cold rain. At 35 in third, the bucking was extreme. At 60 in rain, the GS1100 wouldn’t run on all four cylinders at cruising rpm. either due to extreme leanness (caused by extra-dense, extra-cold, extra-moist air) or super-cooling of the engine by the falling and splashing rain water. Pulling out the choke helped, but if we owned a GS1100 we'd (don’t tell the EPA) tamper with the carburetor jetting.

The clutch on our test bike wasn’t properly adjusted when we received the bike, making finding neutral impossible at a stop. Screwing out the cable adjustor (there is no adjustment at the case, since a rack-and-pinion clutch release is used) eliminated the problem in street use, but it quickly showed up again at the dragstrip. After five hard runs the clutch wouldn’t disengage for power shifts. After adjustments and cooling time, the clutch worked 'well enough for the best pass of the day,

11.39 at 118.42, but never worked perfectly. It was either engaging too suddenly (grabbing off the line, causing wheel spin) or delaying the shift from first to second by dragging or causing the transmission to stick in gear by failing to disengage under power. No pass was perfect, although the times steadily dropped from 11.50s through 11.40s to 11.39. On one pass where the bike demanded that the rider close the throttle to shift into third (after already trying to powershift without success) the GS1100 still ran 11.47. If all had gone perfectly with no clutch trouble, the elapsed time should have been at least low 11.30s and probably 11.20s.

To put it all together, think of the overwhelming peak horsepower of 1979 CBX. Imagine the brutal, lunging mid-range of the 1978 XS11. Combine the two into one engine. That’s the GS1100.

Now consider the plush, long-haul comfort of the XS11. Fantasize about the excellent handling of the GS1000. Once again, combine the two, because the GS1100 gives the rider his choice with 60 seconds spent making suspension adjustments.

With power, handling and comfort, the GS1100 is the best superbike money can buy.

View Full Issue

View Full Issue