Castre Gloves

EVALUATION

A New Curve to Motorcycle Gloves

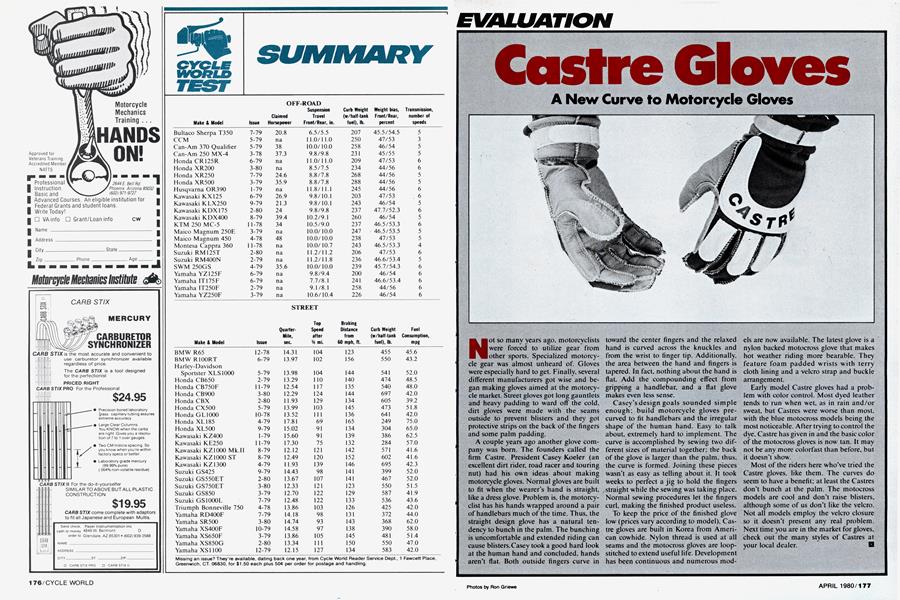

Not SO many. years ago. motorcyclists were forced to utilize gear from other sports. Specialized motorcycle gear was almost unheard of. Gloves were especially hard to get. Finally, several different manufacturers got wise and began making gloves aimed at the motorcycle market. Street gloves got long gauntlets and heavy padding to ward off' the cold, dirt gloves were made with the seams outside to prevent blisters and they got protective strips on the back of the fingers and some palm padding.

A couple years ago another glove company was born. The founders called the firm Castre. President Casey Koeler (an excellent dirt rider, road racer and touring nut) had his own ideas about making motorcycle gloves. Normal gloves are built to fit when the wearer’s hand is straight, like a dress glove. Problem is, the motorcyclist has his hands wrapped around a pair of handlebars much of the time. Thus, the straight design glove has a natural tendency to bunch in the palm. The bunching is uncomfortable and extended riding can cause blisters.Casey took a good hard look at the human hand and concluded, hands aren’t flat. Both outside fingers curve in toward the center fingers and the relaxed hand is curved across the knuckles and from the wrist to finger tip. Additionally, the area between the hand and fingers is tapered. In fact, nothing about the hand is flat. Add the compounding effect from gripping a handlebar, and a flat glove makes even less sense.

Casey’s design goals sounded simple enough; build motorcycle gloves precurved to fit handlebars and the irregular shape of the human hand. Easy to talk about, extremely hard to implement. The curve is accomplished by sewing two different sizes of material together; the back of the glove is larger than the palm, thus, the curve is formed. Joining these pieces wasn’t as easy as telling about it. It took weeks to perfect a jig to hold the fingers straight while the sewing was taking place. Normal sewing procedures let the fingers curl, making the finished product useless.

To keep the price of the finished glove low (prices vary according to model), Castre gloves are built in Korea from American cowhide. Nylon thread is used at all seams and the motocross gloves are loopstitched to extend useful life. Development has been continuous and numerous models are now available. The latest glove is a nylon backed motocross glove that makes hot weather riding more bearable. They feature foam padded wrists with terry cloth lining and a velcro strap and buckle arrangement.

Early model Castre gloves had a problem with color control. Most dyed leather tends to run when wet, as in rain and/or sweat, but Castres were worse than most, with the blue motocross models being the most noticeable. After trying to control the dye. Castre has given in and the basic color of the motocross gloves is now tan. It may not be any more colorfast than before, but it doesn’t show.

Most of the riders here who’ve tried the Castre gloves, like them. The curves do seem to have a benefit; at least the Castres don’t bunch at the palm. The motocross models are cool and don’t raise blisters, although some of us don’t like the velcro. Not all models employ the velcro closure so it doesn’t present any real problem. Next time you are in the market for gloves, check out the many styles of Castres at your local dealer.

View Full Issue

View Full Issue