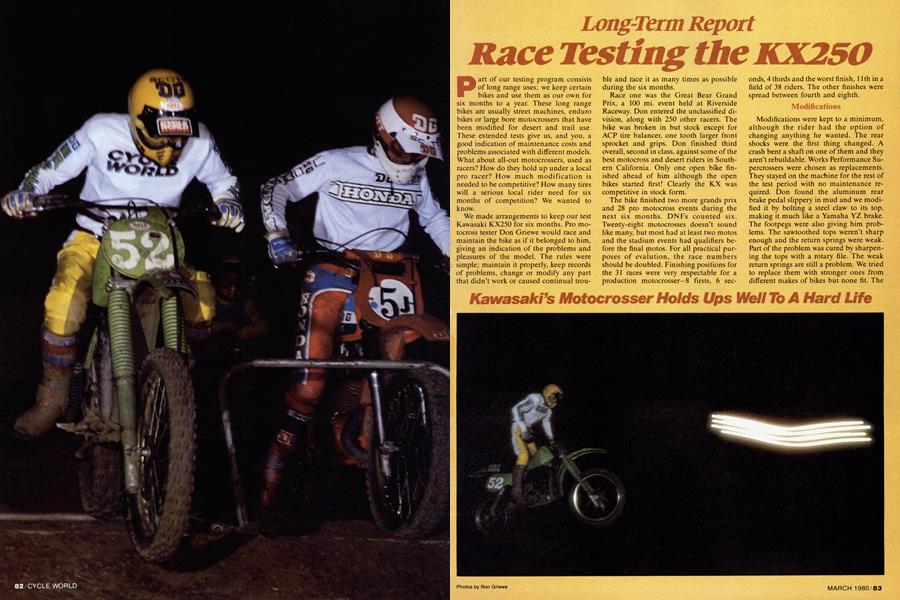

Long-Term Report Race Testing the KX250

part of our testing program consists of long range uses; we keep certain bikes and use them as our own for six months to a year. These long range bikes are usually Street machines, enduro bikes or large bore motocrossers that have been modified for desert, and trail use. These extended tests give us, and you, a good indication of maintenance costs and problems associated with different models. What about all-out motocrossers, used as racers? How do they hold up under a local pro racer? How much modification is needed to be competitive? How many tires will a serious local rider need for six months of competition? We wanted to know.

We made arrangements to keep our test Kawasaki KX250 for six months. Pro motocross tester Don Griewe would race and maintain the bike as if it belonged to him, giving an indication of the problems and pleasures of the model. The rules were simple; maintain it properly, keep records of problems, change or modify any part that didn’t work or caused continual trouble and race it as many times as possible during the six months.

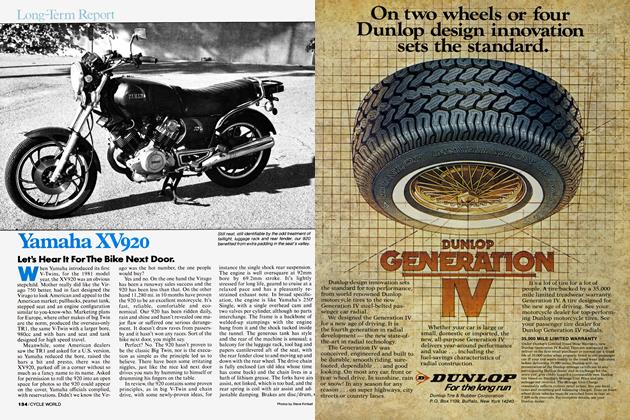

Race one was the Great Bear Grand Prix, a 100 mi. event held at Riverside Raceway. Don entered the unclassified division, along with 250 other racers. The bike was broken in but stock except for ACP tire balancer, one tooth larger front sprocket and grips. Don finished third overall, second in class, against some of the best motocross and desert riders in Southern California. Only one open bike finished ahead of him although the open bikes started first! Clearly the KX was competitive in stock form.

The bike finished two more grands prix and 28 pro motocross events during the next six months. DNFs counted six. Twenty-eight motocrosses doesn’t sound like many, but most had at least two motos and the stadium events had qualifiers before the final motos. For all practical purposes of evalution, the race numbers should be doubled. Finishing positions for the 31 races were very respectable for a production motocrosser—8 firsts, 6 seconds, 4 thirds and the worst finish, 11th in a field of 38 riders. The other finishes were spread between fourth and eighth.

Modifications

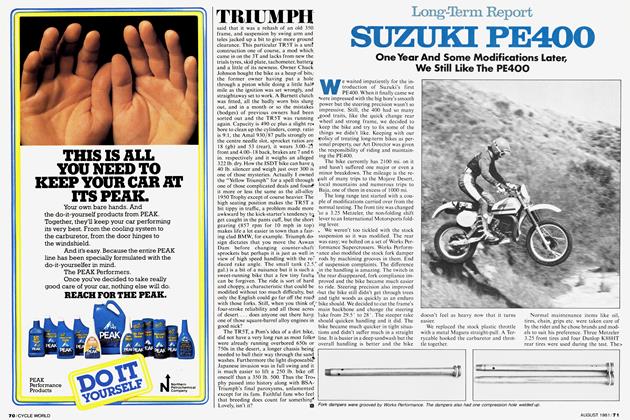

Modifications were kept to a minimum, although the rider had the option of changing anything he wanted. The rear shocks were the first thing changed. A crash bent a shaft on one of them and they aren’t rebuildable. Works Performance Supercrossers were chosen as replacements. They stayed on the machine for the rest of the test period with no maintenance required. Don found the aluminum rear brake pedal slippery in mud and we modified it by bolting a steel claw to its top, making it much like a Yamaha YZ brake. The footpegs were also giving him problems. The sawtoothed tops weren’t sharp enough and the return springs were weak. Part of the problem was cured by sharpening the tops with a rotary file. The weak return springs are still a problem. We tried to replace them with stronger ones from different makes of bikes but none fit. The return springs should be heavy duty jobs like Suzuki uses on the RMs. The brackets that hold the rear part of the side number plates broke but we found them unnecessary anyway and left them off. The throttle was changed to a Gunner Gasser and an International Motorsports cable was used. The stock shift lever broke during the 16th race and it was replaced with a folding unit, from International Motorsports. The front brake didn’t stop as well as it could have, so we took a hack saw and cut grooves across the lining at 45° angles. The simple modification increased the braking power considerably.

Kawasaki's Motocrosser Holds Ups Well To A Hard Life

DNFs

The six dnfs were as follows: one crash, one clutch failure, two chain derailments and two seizures. The derailments occurred when the rubber piece that protects the swing arm from chain damage came off and went through the front sprocket. The first seizure occurred at the exhaust bridge and removed some of the Electo-

fusion. We replaced the cylinder and changed the fuel mixture from 60:1 to 50:1. The second seizure was also around the exhaust port but the rear of the cylinder was worn funny, as if dirt had been entering the engine. We replaced the cylinder and air cleaner. A Phase 2 filter was used and we started using Castrol R oil mixed 20:1. Evidently the 60:1 oil wasn’t compatible with the Electrofusion cylinder since the change ended the cylinder problems. The clutch failure occurred on the starting line at Corona Raceway. The bike had 10 pro races on it and the clutch plates should have been inspected before that many races. When the clutch lever was let out, several plates broke and the bike didn’t move. A new set of discs and plates fixed the problem.

Other Problems

The first thing to break was the head stay. It went the third race and repeated the pattern, breaking every three to four races. The rear engine mount, a welded up piece

of steel, also broke twice during testing. The rear bolt for the static arm broke during practice at the seventh race. It was replaced with a harder one and didn’t cause further trouble. About 15 races into the test, Don started racing night stadium events at San Bernardino. The course was very demanding and had several jumps that put the faster riders 15 to 20 feet in the air. Many were air borne for 80 to 90 feet! The chassis on the KX was holding up well until these events were raced. The front fender was the first part to succumb to the torture of the crazy jumps. After 19 races, four at San Bernardino, the bike started looking like a street chopper. The 38mm stanchion tubes had bent just below the lower triple clamps and the bike grew 2 in. longer as a result. About the same time inspection turned up cracked lever pivots and broken seat brackets. These parts were replaced.

The stanchion tubes were fine until four more events were raced at San Bernardino. The giant jumps claimed an other set of stanchion tubes and the steer ing stem also bent. (We raced a new 1980 Husky 390 at the same stadium event and the forks bent the first race.) The steering stem is built into the lower clamp on the KX so we had to replace the complete unit. The stadium events also stressed other parts that had given satisfactory service on normal tracks. The tank bolt bent and the rear frame loop cracked On the pipe side. The D.I.D. front rim had to be replaced every stadium race-it would become so flattened the tire would come off after one race. We tried using larger spokes in the front wheel thinking they were flexing and letting the rim bend. It didn't help. After replacing the rim three times, we finally cured the problem using a Sun rim. The Sun hassince gone through four stadium races with no flattening. We kept looking at the rear wheel and wondering why it didn t give us trouble-the orginal spokes and rim are still on the bike

Normal Maintenance Parts

The KX has had a tough life and naturally, needed a lot of chains and sprockets; five sets to be exact. The aluminum chain guide was replaced once, after a thrown chain destroyed it. Three sets of cables have been worn out and the grips have been changed a dozen times. Tires were a big expense. Don used up 16 tires; 10 rear and six front. Tire choices were Goodyear and Metzeler fronts, Goodyear and Dunlop rears.

Conclusions

The KX made it through six months of torture testing and is still running although it is pretty well used up. Pro riders are extremely hard on equipment and six months of intensive racing is a long time. The frame only cracked once, the left side of the rear ioop, in spite of the torturous stadium jumps. The aluminum swing arm didn't need any maintenance other than greasing. When the frame and swing arm stay together under a pro racer, they are strong. The Kawasaki KX250 was competi tive and held up well considering its hard life. We learned about the proper oil mix ture the expensive way. We recommend you use Castro! R or a comparable oil that can be mixed at 20 or 25:1. Oil is cheap when the alternative is buying a new cylin der. The KX250 cylinder retails for $156. A seizure with the Electrofusion cylinder or a chrome lined cylinder (like Honda's CR) means cylinder replacement. We prefer boreable steel lined cylinders like Yamaha, Suzuki, Can-Am, Husqvarna, Maico, KTM and most other manufacturers have. A bore job usually costs around $15. The KX transmission held up great. It didn't break any gears, always shifted smoothly and its five-speeds have perfect ratios.

The KX proved reliable (for a racer), and competitive. Its main components; wheel hubs, frame and swing arm, held up well. The KX250 will give an owner many hours of fun and stay together reasonably well. We liked it.