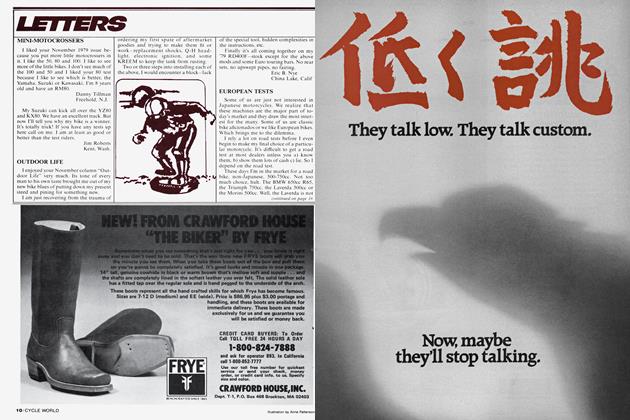

How the Numbers Work

For those who are keen to work out a few of the formulas that apply to springs, here goes.

The relationship between the spring's load (L), deflection (e) and spring rate (R) is as follows:

where L is in pounds (lb.), d is in inches (in.) and R is in lb/in.

When a number of springs are mounted in series, that is, end to end as you would have with a set of springs on a single damper, you add the reciprocals of each spring rate to find the reciprocal of the total rate, as follows:

where R is the total rate and r,, r2, r3 are the spring rates of the various springs up to any amount.

The relationship between the spring rate, the spring’s nominal diameter, the number of turns and the diameter of the spring wire is more complex. Where d is the wire diameter, n is the number of turns, R is the rate and D is the nominal diameter at the centre line of the spring wire, then:

G is the constant that relates the elastic deflection of steel with an applied load. For spring steel the value can be taken as 12,000,000 lb/sq.in. or 12 x 106lb/sq.in. All other values are in inches and the spring rate comes out in lb./in. or pounds per inch. The number of turns used in the equation does not include the two end turns that are used to locate the spring.

You will see that while the number of turns (n) of the spring can provide a fine adjustment of the spring rate, the rate is dependent on the fourth power of the diameter. So a ten percent change in the spring wire diameter can give a 40 percent increase in the rate. Similarly so with the nominal diameter of the spring, the cube root of which affects the rate. EB