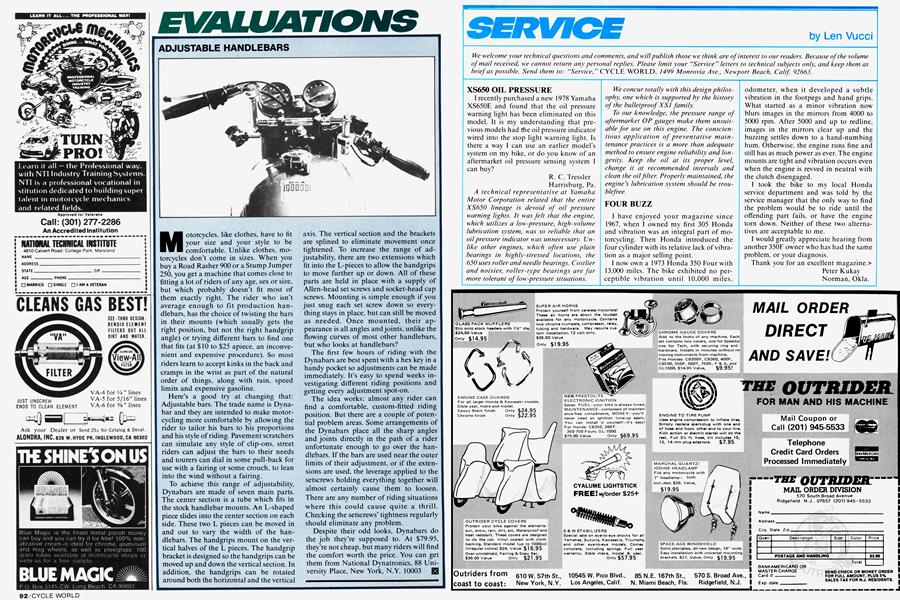

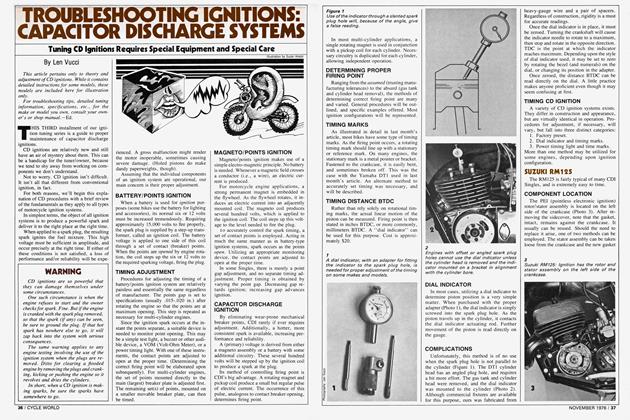

SERVICE

Len Vucci

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service” letters to technical subjects only, and keep them as brief as possible. Send them to: “Service, ’’ CYCLE WORLD. 1499 Monrovia Ave., Newport Beach, Calif. 92663.

XS650 OIL PRESSURE

I recently purchased a new 1978 Yamaha XS650E and found that the oil pressure warning light has been eliminated on this model. It is my understanding that previous models had the oil pressure indicator wired into the stop light warning light. Is there a way I can use an earlier model’s system on my bike, or do you know of an aftermarket oil pressure sensing system I can buy?

R. C. Tressler Harrisburg, Pa.

- -A technical representative at Yamaha Motor Corporation related that the entire XS650 lineage is devoid of oil pressure warning lights. It was felt that the engine, which utilizes a low-pressure, high-volume lubrication system, was so reliable that an oil pressure indicator was unnecessary. Un like other engines, which often use plain bearings in highly-stressed locations, the 650 uses roller and needle bearings. Costlier and noisier, roller-type bearings are far more tolerant of low-pressure situations.

We concur totally with this design philosophy, one which is supported by the history of the bulletproof XS1 family.

To our knowledge, the pressure range of aftermarket OP gauges make them unsuitable for use on this engine. The conscientious application of preventative maintenance practices is a more than adequate method to ensure engine reliability and longevity. Keep the oil at its proper level, change it at recommended intervals and clean the oil filter. Properly maintained, the engine’s lubrication system should be troublefree.

FOUR BUZZ

I have enjoyed your magazine since 1967, when I owned my first 305 Honda and vibration was an integral part of motorcycling. Then Honda introduced the four cylinder with its relative lack of vibration as a major selling point.

I now own a 1973 Honda 350 Four with 13,000 miles. The bike exhibited no per ceptible vibration until 10.000 miles.

odometer, when it developed a subtle vibration in the footpegs and hand grips. What started as a minor vibration now blurs images in the mirrors from 4000 to 5000 rpm. After 5000 and up to redline, images in the mirrors clear up and the buzzing settles down to a hand-numbing hum. Otherwise, the engine runs fine and still has as much power as ever. The engine mounts are tight and vibration occurs even when the engine is revved in neutral with the clutch disengaged.

I took the bike to my local Honda service department and was told by the service manager that the only way to find the problem would be to ride until the offending part fails, or have the engine torn down. Neither of these two alternatives are acceptable to me.

I would greatly appreciate hearing from another 350F owner who has had the same problem, or your diagnosis.

Thank you for an excellent magazines The engineering department at American Honda Motor Corp. suggested several possible causes for the vibration you describe.

Peter Kukay Norman, Okla.

Although you state the bike has been running fine, have a cylinder compression check taken. Uneven firing impulses from a single cylinder can throw off the engine's dynamic balance.

Way down on the list of probables, a loose HyVo primary chain could conceivably cause some vibration. In this application, a loose primary chain will normally also produce a rattling or hammering sound.

More common to touring bikes such as the Gold Wing, the installation of touring accessories can induce vibration in an otherwise smooth bike. Such items as luggage racks, highway pegs, and engine guards can, under certain conditions, set up resonant vibrations which occur within a relatively narrow frequency (engine speed) band. If the installation of such an accessory coincided with the initiation of the vibration, remove it to make a positive determination.

If the accessory is indeed the cause, substitution of a different type of unit or a modification in mounting configuration should eliminate the problem.

The same principle applies even to handlebars, where substitution of an accessory bar may cause a buzzing at the grips. As an indication of the ‘fine tuning" involved, Honda has gone so far as to install lead plugs in the bar tips to lower the resonant frequency.

LEAKY NEEDLE VALVES

Despite its newness, it has been plagued by a problem in the carburetors. Occasionally, when the engine is off and the fuel petcock is on, gas will pour out of the overflow tubes and on to the floor.

I have replaced all four needles and seats; two were parts from complete kits, and two were purchased separately. They differ in that the springs in two of the needles are stiffen making float level adjustment difficult.

A friend told me that switching to needles with neoprene tips will cure the problem. Please advise me in this matter, as it is very frustrating.

Horace L. Mills Bradenton, Fla.

First, you should determine which carb (or carbs) is responsible for the leakage. There's no use “fixing" four carbs if only one is malfunctioning. Next time the leaking evidences itself trace the wet vent hose back to the guilty carb, then remove its float bowl. Inspect the bowl for sediment, which could prevent proper needle valve sealing> Tank rust, caused by high humidity, could pass through a defective filter or screen, and into the area of the needle valve and bowl.

More likely is that there is a mechanical problem in the float system. If the bike sat idle for an extended length of time, there is a chance that fuel deposits on the hinge pin could be causing sticky float action. If the float operates freely, remove it, and check it for leaks. If it contains liquid gas it is defective, and should be repaired, if possible, or replaced.

The needle and seat should be inspected for wear, unlikely in your case, then the float should be reinstalled. Set the float level according to factory specs, then replace the bowl.

If you `ye performed these steps properly you'll not have to worn' about overflow any further.

HEADLIGHT BOOST

I found your article on boosting headlights in the June issue most interesting as my Yamaha XT500 headlight is marginal at best. However, why didn’t you simply move the headlight tap on the generating coil down to the point where you could drive a 6-volt quartz-halogen light? You would most likely have to rewind at least the headlight portion of the coil with heavier wire, but the rest of the electrical system could be left stock. This would make the conversion substantially cheaper than the one presented for the XT500.

Presumably the stock regulator would be able to carry the larger current if the headlight burned out, but this is only speculation as I was unable to find any information on the stock regulator.

Any comments you might have on the above suggestion would be appreciated

William M. Hurni North Wales, Pa.

A straight 6-volt conversion would be cheaper, but we felt that the 6/12 hybrid system was better for a number of reasons.

First, the stated method required a minimum of time and expertise, compared to the effort required to disassemble, rewind, and reassemble the magneto. Fifteen or so dollars for an additional voltage regulator and signal flasher is a relatively small price to pay for the savings in time and effort.

The 6-volt, 55-watt QH lamp draws twice as much current as the 12-volt version. The XT's wiring harness, which was capable of handling the 12-volt QH bulb's current needs, would be overtaxed by the requirements of a 6-volt QH bulb. For a straight 6volt conversion, the stock headlight wiring would have to be replaced with heavier wire.

Procurement of replacement 12-volt QH bulbs is easier than for 6-volters, as more auto supply houses stock them. If you did blow a 6v QH bulb on the road and could not find a replacement, you'd be forced to install a conventional sealed-beam. IS