New Ideas In Tools

CYCLE WORLD hears about many new products each month. We choose tile ones we think would be of the most interest to our readers. We obtain a sample we can test and proceed with an evaluation that is just as thorough as the one we give the bikes we test. We can't test everything, but if you have apreference drop us a line and we'll do our best to obtain the product and pass on our test information.

LINK CLIP POPPER

More a gadget than a tool, but skip that. Those who enjoy leafing through catalogs in hope of turning up some little item worth collecting won’t be able to resist this one.

Master links clips are a bother. They resist all one’s efforts to snap them on and off and most of the time the home tuner is forced to wrestle the link with pliers and screwdriver tip. Not good.

Honda of Mineóla has a gadget designed with this hassle in mind. It’s a metal casting with the handle end dipped in some sort of rubbery stuff'. The thin end has a blunt tip and there are two grooves cut just aft of the tip. What one does is slide the end of the popper into the slot of the clip, and twist. The grooves catch the sides of the clip and force them apart and off the peg of the link proper. Push and the other end of the clip comes off the other peg. To replace the clip, reverse the above.

Fairness compels the note that this nice little toy didn’t always work as well as the description indicates. A #520 or larger chain uses master links and clips which are a fraction large for the popper we got. So we could spread the clip most of the way, then lever the clip with a screwdriver, just like before.

Smaller chains can be persuaded, however and either way, we’d hate to let a gadget go past without paying some attention.

The link clip popper sells for $2.49, from Honda of Mineóla, 336 Jericho Turnpike, Mineóla, N.Y. 11501. Or send one dollar for their catalog and you can browse for yourself.

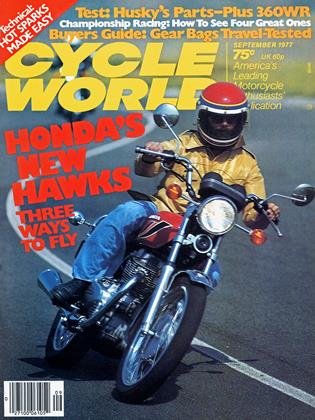

BOLGER IMPACT DRIVER

Joe Bolger is a motorcyclist/inventor. The two words become one. because what Bolger does is invent tools and improvements for motorcycles.

The device shown here is his latest. It’s an impact driver with a difference. A patented difference. Bolger’s driver does what other drivers do, that is. free jammed Phillips-head screws, but Bolger’s system doesn’t need a hammer and it doesn’t have a complicated internal system of rachets. Best of all, Bolger’s driver can put new slots in a screwhead that's been mauled beyond normal repair.

The system is simple. There’s a T handle with a sliding weight. At the other end of the handle is a socket. The driver comes with large and small screwdriver heads and large and small cutting heads. Put a head into the socket and fasten with the keeper nut. Place the head in the screw to be removed.

The end of the sliding weight facing the socket has a deep V. Upstream from the socket is a tube with stoppers. With the driver held firmly against the offending screw, rotate the weight until the V is offset in relation to the stoppers. For removal, the V goes to the left. To tighten, place the V on the right. To cut a new slot in a damaged screw head, put the V at dead center.

With handle firmly against the screw head, briskly slide the weight against the stopper. The offset sharply twists the head and the impact keeps the screwdriver firmly against the screw.

We've been using the Bolger driver in our shop and it works. Does all that the standard impact driver does, plus it’s easy to use and we don't have to search for a hammer each time. We have removed damaged screws. Also we have not removed one stubborn damaged screw in our collection, but not even Joe Bolger promises miracles.

If there is a drawback to the Bolger driver it’s that heretofore the driver has been sold for use in repair shops. The driver is sold to shops by Full Bore and Full Bore has no firm retail price for the driver. Their policy is to advise interested parties to check with the nearest Full Bore dealer and ask him what he’ll sell the driver for. (Dealer cost is less than $20, so you’ll have at least a starting point for negotiations.) If you don’t know a Full Bore retail outlet, write or call Full Bore East, 780 Main St., Holden, Mass. 01520 (617) 829-6556, or Full Bore West, 13712 Alma Ave., Gardena, Calif. 90249 (213) 532-9311.

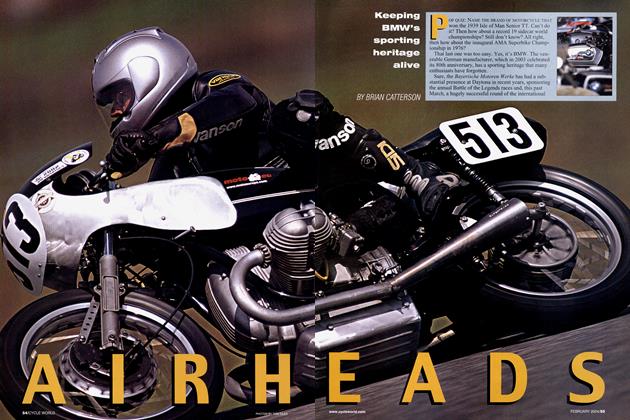

THREE-WAY WRENCH

Another different bit of experimentation from Honda of Mineóla is this threeway socket wrench. As you can see, the wrench is in the shape of a T. Each end has a socket, in either 10 mm, 12 mm or 14 mm.

Those sizes are the most popular with the factories, so the average tool kit contains one wrench in each size. For routine service one frequently needs a wrench on each end of the bolt. The three-way wrench thus completes the set.

More useful perhaps is a three-way wrench off road. Our wrench lives in an enduro tool bag strapped on the rear fender of a staff-owned bike. It packs easily into the bag without displacing anything else. (Always room for one more item if you pack carefully.) During rest stops the rider whips out the ol’ three-way and does a quick tour of the machine, tightening and checking the triple clamps, shock mounts, axle nuts, etc., using the one wrench and not having to dig down into the tool bag itself. The three-way wrench is nice to have along.

Price is $4.95. Honda of Mineola’s address, again, is 336 Jericho Turnpike, Mineola, N.Y. 11501.