PROJECT FUN 'N TRIALER

Everything About Assembling a Kit Bike Turns Out to be Harder than it Looks

Mike Obermeyer

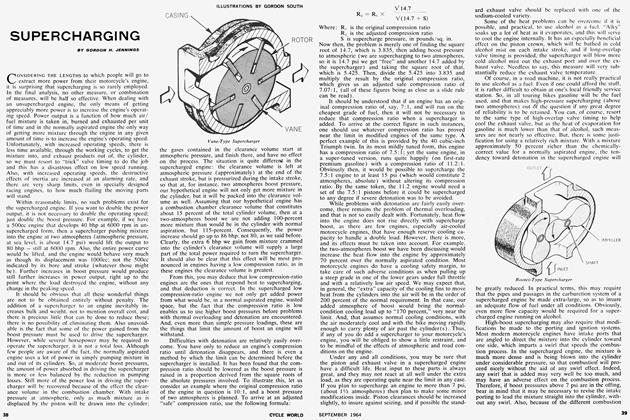

When I first got involved in building my "mini-RTL" trials bike I thought it was going to be simple and cheap. My friends at the Budget Bog Wheeler in Denver had fixed me up with a Sammy Miller HiBoy frame at a good price, and my compadre Bob Nickelsen, manager of American Honda's trials team in Gardena, California, had built me a beautiful little TL-125 engine, bored and stroked to 173 cc. All I had to do was put it all together and I'd have a super trick lightweight trials bike for a small investment. right? Wrong . . .

Nick sent along various suspension parts and other bits and pieces, including wheels and brakes, pipe, sprockets and front suspension bits. I returned from the Greyhound freight office in a frenzy of incipient productivity. Or to be more realistic, I knew that if the donee of all these goodies didn't get them assembled posthaste, the donors might plead unjust enrichment and commence a self-help replevin action. People kept calling me up and saying. “When is that little hummer gonna be finished?” I went to the garage for four or five hours of pleasant work.

After four or five hours. I had managed to get the engine mounted, sort of.

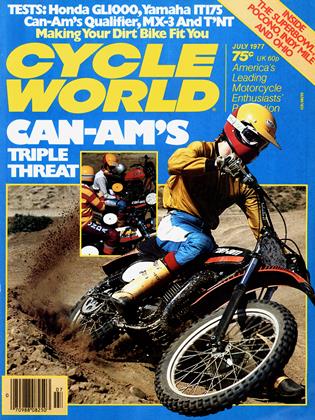

The main problem was that nothing fit exactly. The Honda front motor mount, which is detachable and w raps around the downtube. had to be relieved to fit against the plate to which the bash plate bolts on in front. Then the cast-on bosses on the bottom of the crankcase (used for footpeg mounts on other versions of the 125) had to be ground down to clear the bash plate.

After the rear engine mount bolts were inserted, the front engine mount had to have its bolt holes made egg-shaped in order to stretch an extra sixteenth of an inch or so. Finally, the engine had to be forced sideways to bring the front mount holes in approximate conjunction with the corresponding holes on the engine, the bolts inserted, and then the engine forced in the opposite direction to mate up the engine bolts with the mount bolts on the opposite side. I sent a rough draft of my problems to my old friend Sam Miller, who advised me that the center should be cut from the front mount, making two separate plates. This should facilitate engine placement, although some strength would be lost. Sam also recommended mounting the engine with the bash plate removed.

Having gotten the hard part out of the way I congratulated myself, and started to finish up the minor detail work, which included the following minor details:

No rear brake anchor strap. One had to be fabricated with a rather bizarre offset. My friend Bill Thomas, of Bill Thomas Motors in Denver, was pressed, in a state of moderate dudgeon, into service. Bill bent up a strap out of spare Husqvarna parts, and also modified the steering head stem.

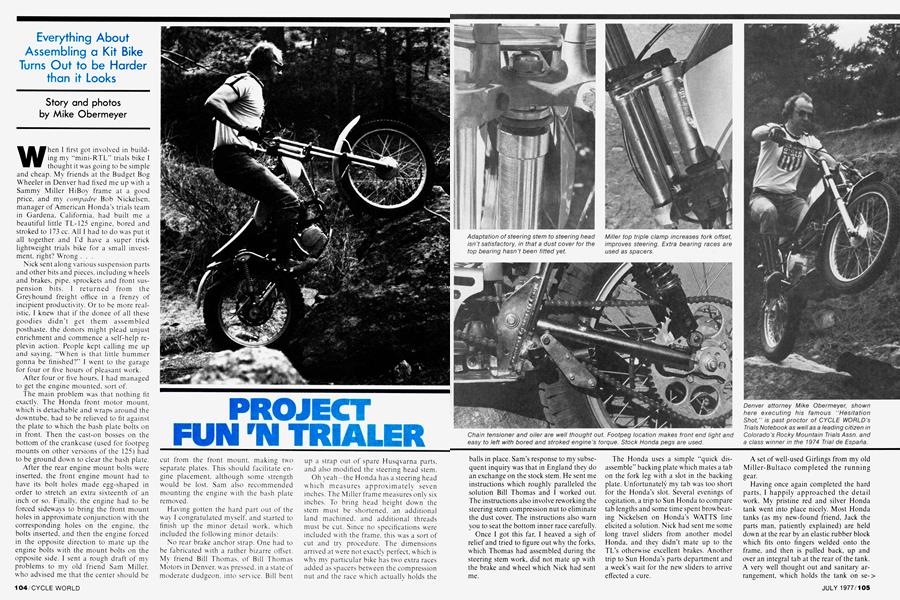

Oh yeah—the Honda has a steering head which measures approximately seven inches. The Miller frame measures only six inches. To bring head height down the stem must be shortened, an additional land machined, and additional threads must be cut. Since no specifications were included with the frame, this was a sort of cut and try procedure. The dimensions arrived at were not exactly perfect, which is why mv particular bike has two extra races added as spacers between the compression nut and the race which actually holds the balls in place. Sam’s response to my subsequent inquiry was that in England they do an exchange on the stock stem. He sent me instructions which roughly paralleled the solution Bill Thomas and I worked out. The instructions also involve reworking the steering stem compression nut to eliminate the dust cover. The instructions also warn you to seat the bottom inner race carefully.

Once I got this far, I heaved a sigh of relief and tried to figure out why the forks, which Thomas had assembled during the steering stem work, did not mate up with the brake and wheel which Nick had sent me.

The Honda uses a simple “quick disassemble” backing plate which mates a tab on the fork leg with a slot in the backing plate. Unfortunately my tab was too short for the Honda’s slot. Several evenings of cogitation, a trip to Sun Honda to compare tab lengths and some time spent browbeating Nickelsen on Honda’s WATTS line elicited a solution. Nick had sent me some long travel sliders from another model Honda, and they didn’t mate up to the TL’s otherwise excellent brakes. Another trip to Sun Honda’s parts department and a week’s wait for the new sliders to arrive effected a cure.

A set of well-used Girlings from my old Miller-Bultaco completed the running gear.

Having once again completed the hard parts, I happily approached the detail work. My pristine red and silver Honda tank went into place nicely. Most Honda tanks (as my new-found friend, Jack the parts man, patiently explained) are held down at the rear by an elastic rubber block which fits onto fingers welded onto the frame, and then is pulled back, up and over an integral tab at the rear of the tank.

A very well thought out and sanitary arrangement, which holds the tank on se-> curely and insulates it from frametransmitted vibration.

When I tried it the damn rubber split.

Only a minor problem—the rear finger mounts were too close to the forward tank mounts (or Honda made my tank too long) and the rubber just wouldn’t stretch that far. This problem has apparently been remedied on later model frames. The inelegant solution was to tape the rubber mount onto the fingers, and use the pressure exerted by the “slide under” tabs at the front of the seat to jam the seat against the tank, thus holding it in place. Then when I bolted the rear of the seat to the frame tabs provided, the tank hopefully wouldn’t go away.

Except . . .

The frame tabs didn’t fit the seat, and I was faced with the prospect of either fabricating new rear mounting brackets for the seat (sanitary but time-consuming) or drilling new holes in my beautiful nickelplated frame.

I drilled the frame.

By this point, my patience was flagging. I had also determined that:

The expensive, beautifully designed Honda airbox wouldn’t fit.

The coil-condenser assembly which Nick had sent didn’t fit.

The head steady, which Nick insisted was very desirable, didn’t steady nothin’, ’cause it didn’t fit, and only had one (conjectural) attachment point on the frame, where the stock model has two.

Even if I had a head steady (which by then I did, courtesy of Bill Thomas) it sure as hell wasn’t going to clear the coil assembly which Nick had sent me, and which now reposed on a cobby bracket I had dreamed up. Elegant solution: Forget the blasted head steady. Nick tells me he can’t remember whether the coil is stock. I guess it is not.

I've been advised by Sam that later model frames have been revised to eliminate the air filter and head steady problems.

Oh. yes. The tank I had special-ordered didn't have a petcock. Neither did Sun Honda, so I ordered one. Another week's wait.

After all this, you've probably guessed how the bike works. Crummy, right? Wrong!

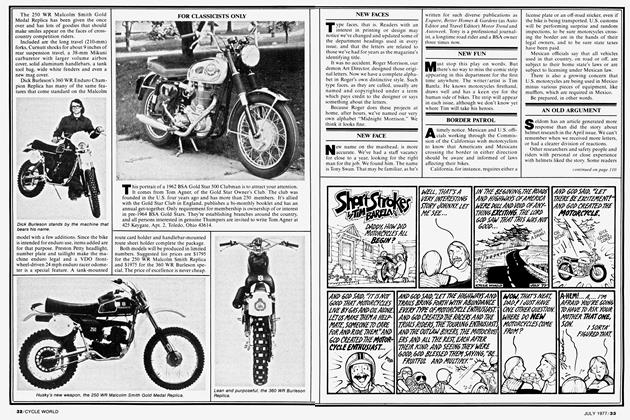

The RTL-173 (with apologies to Honda R&D) is a sheer delight. At 186 pounds wet, it is light, the steering is quick and precise, and the engine is amazingly torquey and revs so freely that first gear will let you creep around turns and then scream up hills you would take in second gear on a two stroke. The bike is pretty (I love nickel-plated anything) and easy to keep clean. The rear suspension, which exhibits a fair cantilever, after RTL prototype practice, is excellent. Ground clearance is more than adequate. All the controls work smoothly and crisply.

My complaints with the workings of the machine are minor. The progressive throttle, with its large, spiral drum, is too quick for my aging, palsied throttle hand. The forks are definitely not up to state-of-theart Spanish, or TL-250, levels.

What are the drawbacks? Well, you don't have the fierce power of a large Spanish trialer. The little four-stroke requires a finer throttle hand, and more anticipation. Large squirts of horsepower to cure panic situations are not readily available. The compression braking effect of the engine is initially disconcerting, but a faster idle cures this.

The overall impression is one of fun, and tractability. The engine is willing and flexible, and the bike is so light that when you switch back to a larger bike it feels like a top-heavy toad. Every once in a w'hile you wish you had more oats, but I believe the Honda will be quite competitive in nonserious “club” events. It’s great fun to ride, and typically Miller in its handling: weight outside and forward on turns, well forward on climbs. Would I do it again? Sure, now that I know how. I'm still not exactly sure why the early frame I have has so many minor frustrations built into it, but Sam assures me that everything works on the newer models, which now incorporate a head steady and proper tank mounts. Sam sent me the instruction sheets which should have come with the frame—they would have made life much easier. Don’t start work without them. I think it would be cheaper to buy a used TL-125 and convert it; buying a motorcycle part bv part is expensive, even when the big components are donated.

All in all, a very satisfying exercise. 13