SERVICE

Len Vucci

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your "Service" letters to technical subjects only, and keep them as brief as possible. Send them to. "Service," CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif 92663.

HORNS OF A DILEMMA

I recently purchased a set of Fiamm horns for my Honda 750. When I attempted the installation I encountered a major obstacle. The Honda horn has two terminals, both of which have wires connected. The Fiamm horn, on the other hand, has only one. Connecting the Fiamm using only one of the two wires resulted in a) nothing, or b) continual blowing of the horn when the key was turned on.

How can the system be modified for proper horn operation?

Cliff Bird Costa Mesa, Calif.

There are two common ways in which the horn is wired into the motorcycle's electrical circuit. The single-wire horn, such as your Fiamm, is connected through the horn switch to a hot line. When the switch is depressed, current fiows from the battery, through the switch, through the horn, and to

ground.

The dual-terminal horn, like the Honda horn, is wired differently. One side of the horn is connected to a hot line, the other to the horn button. Pushing the button com pletes the circuit: from battery, through horn, through switch, to ground.

Adaptation of the single-terminal horn to your dual-terminal system requires the use of a horn relay. This relay may be purchased for a couple of bucks from most auto parts stores. It has three terminals: horn, battery and switch. For your Honda, the light green horn wire connects to the relay's switch terminal, the black wire leads to the battery, and the relay’s horn terminal is connected to the horn’s horn terminal, naturally.

Have a blast.

TT500 HOT START

I own a Yamaha TT500C. I would like to inquire as to where I can obtain information on this bike in reference to a CDI unit.

The bike will not start when hot, and the points always look dirty and pitted. I bought a shop manual, and I keep the settings (carb, valves, points, etc.) given in the book. I’ve changed the points, condenser and plug frequently, but the problem is still there.

Some say it is the carb but I think there is something getting weak in the electrical system as the motor gets hot. When cold, the bike will start on the first or second kick, no matter how long it has been sitting.

Several of my friends are experiencing the same problem, and any information you could provide would be greatly appreciated.

James Slebzak Annapolis, Md.

Several of our friends, including Test Editor Ron Griewe, have also experienced the problem you describe. After logically troubleshooting the electrical system, replacing suspect components and retesting, the problem remained. Carburetion was ruled out as being the cause, as Ron's bike was used to evaluate several carburetors, none of which relieved the balky hot-start symptom.

After some trial and error experimentation, Ron provided a cure which has proven to be 100 percent successful. Seems the stock condenser, after it is heated by the engine, breaks down electrically, causing the hard-start-when-hot condition. Ron'sfix involves removing the stock condenser and installing an automotive condenser under the gas tank near the ignition coil. His choice is a Mallory #25010 unit, which is available in most auto parts stores.

The condenser lead should be connected to the black wire which leads to the breaker points. The condenser, which comes with two different mounting brackets, should be securely mounted to the bike frame. This will provide a proper electrical ground connection. An alternate method would be to use duct tape to hold the condenser. One of the brackets should then be used to connect a ground wire from the bike's frame to the condenser body.

1-2 CLUNK

As a long time reader of CYCLE WORLD, I have come to respect your opinions as expressed in road tests and

technical articles. Your road tests of the XS750D and XS750-2D Yamahas led me to purchase what has been a near-perfect bike for my needs. In this age of dealers who will not give test rides until the check is in their hands, it is imperative that the buyer have someone like CYCLE WORLD to give unbiased and complete information.

My particular XS750-2D has presented my with only one problem to date; it concerns the operation of the transmission. Your test indicated a large gap in ratio from first to second gear which hampers acceleration. As I didn’t expect a dragster when I purchased the bike, this does not bother me. However, on first-to-second upshift, a loud clunk is distinctly heard. It is similar to older BMW and Harley models. If I shift below 3000 rpm and take my time, a smooth shift can be made. The higher the engine speed, the louder the clunk.

As Yamaha XS750s are few and far between in this area, I have been unable to discuss this with other owners. Did your test bikes exhibit this condition? Would you consider this a normal condition because of the ratios involved? Can you suggest probable cures?

G. R. Craig Virginia Beach, Va.

No, neither of our test bikes nor friends' bikes exhibited the condition you describe. The spread in gear ratios does not have a direct bearing on potential drivetrain play, so we could not say what constitutes a “normal condition ” on that basis.

As to cures, Technical Services at Yamaha International advises you to first have the primary chain tension cheeked. A loose chain could induce excessive drivetrain play which could manifest itself in the 1-2 shift noise. They also recommend you seek assistance from your local dealer, especially if the bike is in warranty. Further information, if necessary, can be obtained from Yamaha International, Customer Service Dept., (714) 522-9471.

KZ650 TIMING

I have a 1977 Kawasaki KZ650 and in learning to tune it myself have encountered a problem. When using a strobe light to check the timing, the marks jump around erratically. This is especially true for the #2-3 timing marks, making it almost impossible to time. Shouldn’t the marks appear to be rock steady?

Sam McClure Richardson, Tex. >

Normally, yes. The symptoms your describe could be caused by one of several problems.

First suspect is the points themselves, as the symptom is more pronounced on the 2-3 side. Make sure the points (even new ones) are cleaned with non-residual contact cleaner, especially if you’ve sanded them to remove pitting. Draw a piece of business card through each set of points to remove any remaining debris. Set the points to the proper gap (0.3-0.4mm or .012-.016 in.) or use a dwell meter (185-195 degrees; 23-24.5 degrees on an automotive 8-cylinder meter).

Next to try is the condensers. Reverse their leads, connecting the 2-3 condenser to the 1-4 points, and vice versa. If the erratic timing shifts to the 1-4 side, you’ve located the problem.

Finally, install new spark plugs if you haven’t done so already. A faulty plug will occasionally cause a varying spark-over voltage requirement, with similar effects to those you’ve noted.

Incidentally, the people at nearby Champion Motors have related a simple bolt-on ignition modification which seems to be worthwhile. The advance unit from a KZ900 can be purchased for about $14. When installed on the KZ650, it provides an advance curve which gives the 650 slightly better response, especially at low rpm.

WATER BUFFALO CONSUMES OIL

I am having a problem with the oil injection system on my 1973 Suzuki GT750. Most 750s get from 600 to 1000 miles per quart of oil but mine wall get only about 300 miles.

The dealer has checked the oil pump setting, changed the pump and we have replaced the throttle cables, but it still uses too much oil. With that much oil I have a hard time keeping my plugs from fouling.

Do you have any suggestions on what to try next?

Bob Craig Hamlin, Tex.

If the metering pump has been properly synchronized to carburetor opening, and there are no leaks in the system, there is one item you might check.

It is possible to install the pump arm on the cam incorrectly, resulting in a 180degree change in cam position. At low speeds the pump would meter much oil, and at higher throttle openings there would be little oil metered.

This condition would produce instant engine seizure on most two-strokes, but because of Suzuki’s CCI lubrication system and the GT’s water cooling, the engine can withstand the abuse.

Check cam positioning against the factory workshop manual, or have a competent mechanic check it for you. |g

View Full Issue

View Full Issue

More From This Issue

-

Up Front

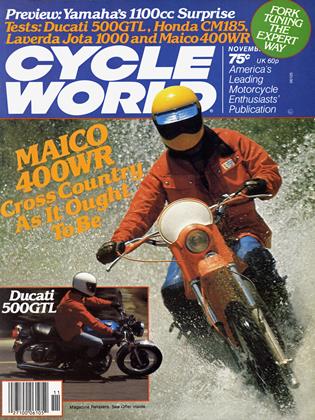

Up FrontSelling the Sizzle

November 1977 By Allan Girdler -

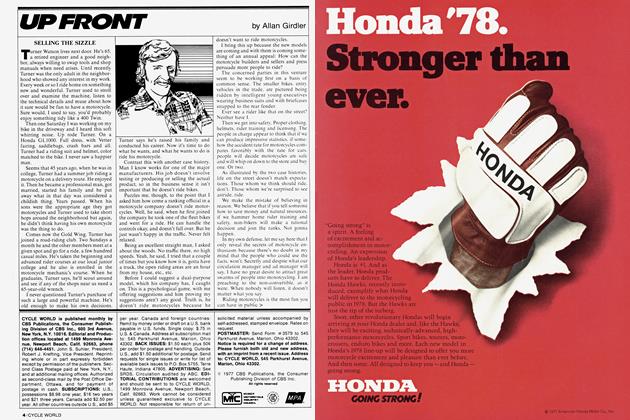

Letters

LettersLetters

November 1977 -

Features

FeaturesToo Much Government Is In Our Future

November 1977 By Lane Campbell -

Features

FeaturesItalian Spoken Here

November 1977 By Jean Crabb -

Roundup

RoundupThe Victory Continues

November 1977 -

Roundup

RoundupA Big Plug For Champion

November 1977