A Technical Analysis Of The Waterpumper

No Need To Call A Plumber

Don Koch

HOW MANY motorcyclists can recall the 600cc Scott, the Velocette LE or the Moto Guzzi V-8?

The Scott was (or is, a few are still produced today) a two-stroke Twin used in the sturdy Scott Flying Squirrel. The Velocette LE employed an opposed Twin 200cc sidevalve engine. And the 500cc Guzzi was a quadra-overhead camshaft (yes, four overhead cams) engineering marvel that powered the awesome Guzzi road racer at speeds up to 178 mph. These little known or largely forgotten motorcycle engines shared one noteworthy feature in common: all were water-cooled.

If this quick walk down memory lane revealed some unfamiliar landmarks, don't feel badly. Although watercooling dates back to the earliest days of motorcycling, water-cooled engines have never captured a significant share of the motorcycle market. Until recently, the water-cooling idea seemed destined (except for exotic two-stroke racing engines) to share the fate of sprung hubs, trailing link forks, split piston engines (CW, March '70) and a host of other interesting though bizarre motorcycle designs.

Then last year Suzuki introduced a water-cooled 750cc two-stroke production engine and now Yamaha has shown a water-cooled rotary engine motorcycle. You cannot buy the water-cooled Yamaha—yet. But the inscrutable Japanese surely have their reasons for returning to the water-cooled notion. Indeed, there is mounting evidence to suggest that watercooled engines may represent the wave of the future in motorcycle engineering.

Even the most outspoken advocates of water-cooling admit that it is not the perfect solution for every motorcycle. But the arguments in favor of water-cooling are founded on sound logic and careful research. No motorcyclist should condemn the notion of water-cooled cycle engines without first examining the evidence—unless he wishes to be in the same position as the man who said: "Don't confuse me with the facts, my mind is already made up."

THE HEAT PROBLEM

Gasoline powered engines produce a vast quantity of heat as the inevitable byproduct of combustion. About one third of the heat yield from combustion is converted into mechanical energy. It is this energy that forces the piston down and turns the crankshaft around. Approximately one-third of the heat simply passes through the exhaust port and out the muffler in the form of hot gasses. The remaining heat of combustion, along with the frictional heat from moving rings, valves, etc., is absorbed by the cylinder head, valves, ports, piston, barrel and crankcase assembly.

The heat of combustion does not harm an engine so long as it is promptly dissipated. In fact, internal combustion engines function properly only after they have absorbed sufficient heat to reach their normal operating temperature. But excessive heat can quickly destroy any engine. As temperatures begin to rise beyond an optimum level, detonation and pre-ignition rob an engine of its power and place destructive loads on the valves, piston, rings and other engine components. The hot pressure waves of gas generated during combustion can bake oil, soften aluminum alloys and crack cast iron.

To make matters worse, the various parts of an engine do not absorb equal amounts of heat. The area around the exhaust port and the middle of the piston crown receive the greatest exposure to high temperatures while the inlet valve (or intake and transfer ports) and the piston skirt generally run much cooler. This uneven heating creates differential rates of thermal expansion, which in turn causes distortion of the head, piston, and cylinder walls. Distortion places additional stress on these components and causes the clearance between moving parts to deviate beyond their factory designed limits. When clearances grow to more than their normal dimensions, gas leakage and blowby occur. When clearances become tight, excessive friction and scoring or seizure occur. Lubricating oil plays an important part in absorbing engine heat. But heat destroys oil, too. Motor oils begin to lose their lubricating properties just as they are most needed to control the destructive temperatures and forces at work in an engine.

THE AIR-COOLED CONCEPT

The oil system alone cannot absorb sufficient heat to maintain a motorcycle at its proper operating temperature. Therefore, most motorcycles produced throughout the world depend on air-cooling to help them dissipate the heat of combustion. Air-cooling may look to be a simple, foolproof method of extracting unwanted heat from an engine. But, in fact, air-cooled motorcycles operate in accordance with complex physical laws. Meticulous design work and precise foundary techniques are necessary for a motorcycle to take full advantage of these laws.

Before a motorcycle can dissipate its surplus heat output, the inner surfaces of the engine must first absorb that heat. Then the heat must be conducted through the metal and across any mating surfaces (as between a valve stem and guide) onto the external skin of the metal. The efficiency of the transfer process depends largely on the fit of the mating surfaces and the thermal conductivity of the material through which the heat passes.

Cast iron and steel are relatively poor conductors of heat. Aluminum will transfer heat at 3.5 times the rate of cast iron, and copper has more than twice the heat conductivity of aluminum. At one time motorcycle manufacturers actually constructed cylinder heads of bronze alloyed with a small amount of aluminum. Bronze heads, however, were costly to produce, difficult to machine, even heavier than cast iron, and subject to rapid wear in the area of the valve seats. Manufacturers therefore soon abandoned copper alloys in favor of aluminum. Although aluminum conducts heat less rapidly than copper, it is far superior in this respect to cast iron and it weighs about 60 percent less. Because aluminum is so much lighter than cast iron, greater quantities of it can be used to create large cooling surfaces. An aluminum cooling fin will be 2.5 times larger than a cast iron fin of the same weight. Therefore, the aluminum fin conducts heat away from the combustion chamber at nearly nine times the rate of an iron fin of the same weight.

Once the heat from combustion reaches the external surfaces of an engine, most of it is dissipated by radiation and convection.

Radiant dissipation transmits heat through air without actually warming the air itself. The heat is emitted in a wave-like form that appears again as heat only when it strikes a solid object. Radiant heating is not a rare phenomenon. Microwave ovens work according to a similar principle. Heat from the sun is transmitted to the earth in the form of radiant energy. Anyone who has basked in the warmth of the sunshine on a clear, windless winter day understands the principle of radiant heat flow. The air is cool, often below freezing, but your face and body become quickly warmed by the sun.

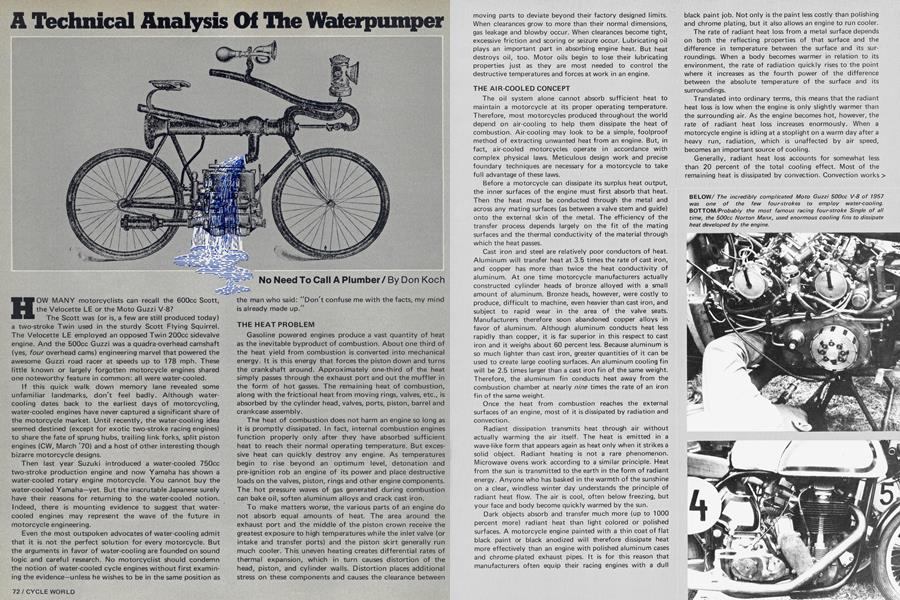

Dark objects absorb and transfer much more (up to 1000 percent more) radiant heat than light colored or polished surfaces. A motorcycle engine painted with a thin coat of flat black paint or black anodized will therefore dissipate heat more effectively than an engine with polished aluminum cases and chrome-plated exhaust pipes. It is for this reason that manufacturers often equip their racing engines with a dull black paint job. Not only is the paint less costly than polishing and chrome plating, but it also allows an engine to run cooler.

The rate of radiant heat loss from a metal surface depends on both the reflecting properties of that surface and the difference in temperature between the surface and its surroundings. When a body becomes warmer in relation to its environment, the rate of radiation quickly rises to the point where it increases as the fourth power of the difference between the absolute temperature of the surface and its surroundings.

Translated into ordinary terms, this means that the radiant heat loss is low when the engine is only slightly warmer than the surrounding air. As the engine becomes hot, however, the rate of radiant heat loss increases enormously. When a motorcycle engine is idling at a stoplight on a warm day after a heavy run, radiation, which is unaffected by air speed, becomes an important source of cooling.

Generally, radiant heat loss accounts for somewhat less than 20 percent of the total cooling effect. Most of the remaining heat is dissipated by convection. Convection works > on the same principle as a household radiator: the surrounding layer of air directly absorbs heat from the metal surface, thereby reducing the temperature of the metal. As the air becomes warmer it rises and cooler air takes its place. Air is a notoriously poor conductor of heat. Its rate of conduction is about 1000 times lower than aluminum. So these air currents are necessary to ensure a flow of fresh cooling air at low speeds, where the natural flow of air over the engine is slight.

AIR-COOLING PROBLEMS

The effectiveness of convection cooling depends on the surface area of the engine and the speed and temperature of the air moving over it. Fins serve both to increase the engine area exposed to the air and to direct the air to various hot spots, where it is most needed. The velocity of the air flowing over an engine is a function of the speed of the vehicle itself, wind speed and direction, and the aerodynamics of each different motorcycle. A motorcycle traveling at moderate speed in still air or into a head wind generally receives an adequate supply of air. But a motorcycle traveling at 40 mph with a 20 mph tailwind has a theoretical airflow speed of only 20 mph.

To further complicate matters, the airflow direction and speed in the vicinity of an engine sometimes bears little relationship to the forward speed of that motorcycle. Pressure differentials and crosscurrents often direct the air flow around a motorcycle engine in different patterns than a manufacturer anticipated. Experiments have shown that as motorcycle speeds increase, a large area of relatively stagnant air often accumulates around the engine head and barrel. Under certain imperfectly understood conditions, the air flow will actually begin to move forward over the engine.

In other words, a rider cannot assume that because his motorcycle is moving fast, the engine is receiving a greater—or even an equal amount of air flow—than it received at lower speeds. Suzuki has begun to experiment with controlled air duct designs for touring bikes, but as yet there exists no adequate theory to predict and direct natural air currents around the engine area of a fast moving motorcycle. Until extensive research allows motorcycle engineers to predict and control the flow of air around an engine, air-cooling design will remain an uncertain art rather than an exact science.

Because the success of an air-cooling system requires a sufficient supply of cool air to absorb engine heat, air-cooled engines must be designed so that their cylinders receive maximum exposure to air currents. The existence of the Henderson and Indian in-line four-cylinder designs and the Ariel Square Four (the two rear cylinders sat directly behind the front cylinders) demonstrate that low compression aircooled motorcycle engines can survive with a severely restricted air supply to the rear cylinders. But the rear cylinder cooling on these engines was known to be marginal. It used to be said of the in-line Fours that the back cylinders got so hot you could see the pistons moving at night. In-line engines, the square design, and V-4 arrangements operating with modern compression ratios would require a water-cooling system to control uneven heating and prevent excessive distortion of critical moving parts.

Horizontally opposed, transverse, and V-Twin engine layouts allow improved levels of air-cooling efficiency. The single-cylinder and opposed Twin (which is roughly equal to two single cylinders laid over on their sides) offer the most uniform cooling characteristics. Because the V-Twin design requires one cylinder to rest behind the other, the rear cylinder has a lower theoretical cooling capacity than the front cylinder. But some designers have partially compensated for this difficulty by offsetting the back cylinder by a small distance to place the rear exhaust port in contact with a fresh air supply.

Multi-cylinder transverse engines provide an adequate air flow to the outboard side of their end cylinders. But the inboard side of these cylinders and the inner cylinders of three and four-cylinder transverse engines receive a less adequate flow of air. The careful design of fin patterns and irregular cylinder spacing layouts can partially overcome these problems. Yet the multi-cylinder transverse engine remains an inherently difficult design to cool properly by means of a natural air flow.

Two-stroke engines have no valves, guides or seats to suffer the consequences of inadequate cooling. Moreover, the uncomplicated head design of a two-stroke engine simplifies the job of constructing a fin pattern that will allow an adequate flow of air around the top of the combustion chamber. But two-stroke engines are especially prone to suffer from inadequate cooling. The reasons for this are quite simple. Twostroke engines lack separate inlet and exhaust cycles. They yield twice as many heat producing explosions asa four-cycle engine operating at the same speed. This high rate of heat production in a two-stroke engine is especially harmful because the heat is distributed unevenly. The exhaust port side of the cylinder becomes hotter than the inlet side, causing the cylinder walls to distort into an egg-shaped pattern (though not as pronounced, of course). Because the top portion of the barrel is hotter than the lower walls and, on a multi-cylinder engine, the inner walls are often hotter than the outside walls, the cylinder also distorts vertically. These problems would be troublesome enough in a four-stroke engine. But they become even more serious in an engine design that requires the piston and cylinder wall assembly to act as a valve regulating the gas flow into and out of the combustion chamber. When cylinder distortion occurs in a two-cycle engine, gas leakage and excessive friction between the rings or piston skirt and the cylinder wall quickly result. This excess friction creates more heat, thereby compounding the problem. It is little wonder that two-stroke engines are more prone to piston seizure than four-stroke engines. It should also come as no surprise to learn that over the past 20 years water-cooling has appeared most often on two-stroke motorcycle engines.

THE WATER-COOLING CONCEPT

Water-cooling employs the same principles of heat transfer by radiation and convection as air-cooling—with the exception that a liquid is used to absorb most of the heat and transport it to the heat dissipating or heat transfer device we call a radiator. Actually, the term radiator is something of a misnomer, for a radiator transfers most of its heat by convection rather than radiation. The outside surfaces of the water jacket, the hoses, and the radiator coils all radiate a small portion of the heat they have absorbed. But somewhere around 70 to 80 percent of the engine heat is transfered by convection at the point where moving air passes through the core of the radiator.

A properly designed water-cooling system offers two principle advantages over a naturally air-cooled engine (one without a cooling fan). First, the overall temperature of the cylinder and head assembly can be considerably reduced. Second, the temperature differential between the hot and cold parts of the engine can also be decreased by directing the water passages in such a manner that the exhaust ports, the inside wall of the cylinder sleeves and other engine hot spots receive the benefit of a disproportionately large share of the circulating water. In other words, water-cooling allows an engine to run cooler and at a more uniform temperature. A water-cooled engine requires a slightly longer period of time than an air-cooled engine to reach operating temperature. But once a water-cooled engine reaches that temperature, its mechanical thermostat will maintain a nearly uniform temperature under most operating circumstances.

Variations in wind speed and direction have some effect on the cooling capacity of a water-jacketed engine due to the different air flow rates over the radiator. But these differences are usually overcome by automatic variations in the thermostat opening. Moreover, water-cooled engines equipped with a crankshaft driven water pump receive a coolant flow that is approximately proportionate to their engine speed. The faster the engine turns, the more quickly a water pump will circulate coolant throughout the engine.

An air-cooled engine pulling up a long grade in a lower gear generates a large amount of heat relative to the cooling capacity of the moving air. A water-cooled motorcycle will receive an equally small amount of air passing through its radiator. But the increased rate of water circulation resulting from the use of a lower gear coupled with a maximum thermostat opening is usually sufficient to compensate for the reduced air flow and increased heat output resulting from a long uphill climb.

A number of additional advantages result from the lower and more uniform operating temperature of a water-cooled engine. The most important benefit is less distortion of the cylinder sleeve, piston, and cylinder head assembly. Because these components are subjected to less stress, they are likely to last longer and require less servicing. The chances of a holed piston crown or piston seizure—which have always been the bane of two-stroke motorcycles—decline substantially. Lower and more predictable amounts of distortion also allow a manufacturer to machine his engine parts to closer specifications, which yields better gas sealing and, often, less friction. Suzuki, for example, claims that its water-cooling system permits a reduction in piston skirt to cylinder clearance from 0.015 in. to 0.002 in.

By lowering the temperature of combustion chamber walls, water-cooling reduces the risk of detonation and pre-ignition. Hot engine power losses, which frequently occur among two-stroke engines, also occur less readily. Water-cooling often enables a manufacturer to safely raise engine compression ratio to extract more power from a given amount of gasoline. Moreover, the lower operating temperature helps preserve the lubricating ability of motor oils.

Heat is the single worst enemy of oil. Heat decreases viscosity, increases the rate of oxidation, and quickly destroys the effectiveness of the various additives included in motor oil. Even a small increase in the temperature of an oil will often drastically reduce its effectiveness or longevity. For example, the oxidation rate of hot oil doubles with each succeeding 15-degree F rise in temperature. So a 5-degree decrease in oil temperature will slow the rate of oxidation-which changes oil into sludge, abrasive compounds and acids—by one-third.

One final advantage of water-cooling is that the layer of water and external jacketing dampen the clatter of pistons and other moving parts. The opportunity to use close tolerances between the piston and cylinder wall further reduces the noise level of a water-cooled motorcycle engine. The result—as the Suzuki 750 readily demonstrates—is a motorcycle so quiet pedestrians look twice to see if it really was a motorcycle that glided by. Motorcyclists who enjoy the orchestra of sounds produced by a conventional bike engine may not appreciate the new sounds of silence emitted by a water-cooled motorcycle engine. But many long distance touring riders and nearly the entire non-motorcycling public will enjoy the additional measure of sound deadening.

THE THERMO-SYPHON ALTERNATIVE

Although the water-cooled Suzuki uses a mechanical water pump to circulate coolant (which is actually a mixture of water and a special corrosion resisting anti-freeze), many water-cooling systems do not require a pump or thermostat.

So long as the top of the radiator is mounted well above the engine and the hoses, along with the passageways, are of large > enough diameter, thermo-syphon action will automatically circulate the water. Thermo-syphon systems have been used with success both on two-stroke motorcycle engines and on Saab and DKW passenger cars.

Thermo-syphon circulation depends on the fact that warm water, because it is lighter, rises upward while the colder water sinks to the bottom of a container. When engine heat warms the water in a cylinder jacket, the water rises upward through a hose to the top of the radiator, and cool water from the bottom of the radiator drains into the lower portion of the jacket to replace the warmer water. As the warm water in the radiator is cooled by convection and radiation, it descends to the bottom and circulates back into the engine jacket.

The thermo-syphon system creates a controlled convection current that supplies the engine with a continuous flow of cooled water from the radiator. Although thermo-syphons generate only a small pressure differential, on the order of a few ounces per square inch, this pressure can create sufficient circulation to cool an internal combustion engine.

Because thermo-syphon cooling systems require no external power source or moving parts, they are an especially attractive method of cooling an engine. But the system must be designed to ensure an effective flow of air across the radiator. As soon as the radiator begins to absorb heat more rapidly than it can dissipate it, the temperature of the water in the top and the bottom of the radiator begins to equalize and the pressure differential will drop toward zero. Soon afterward, the coolant stops circulating and the water in the cylinder jacket begins to boil, with the unhappy consequences known to most motorists.

In practice, the chances of so untoward an event befalling a thermo-syphon equipped motorcycle are quite remote, especially if the radiator is equipped with an auxiliary electric fan. The water-cooled Suzuki has such a fan, which is designed to begin operation whenever the water temperature exceeds 220 degrees F. A thermo-syphon equipped motorcycle would require an additional pressure indicator to activate the fan when the water pressure dropped below a minimum acceptable level. As a further precaution, the radiator assembly can be tilted forward a few degrees from a vertical plane, as Suzuki and Yamaha have done. The forward cant does not significantly decrease the air flow at high speeds. But it will materially aid the upward flow of air across the core at rest, thereby providing additional cooling capacity when it is most needed.

WATER-COOLED DRAWBACKS

Like almost everything else in this world, the advantages of water-cooling are not free for the asking. A rider must pay in a number of ways if he wishes to enjoy the benefits of a water-cooled motorcycle engine.

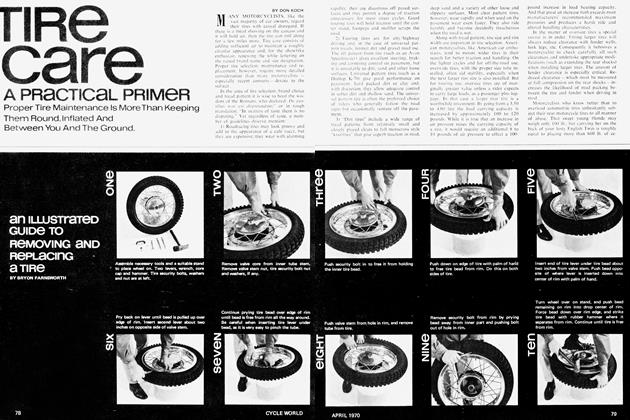

First, there are the additional parts. A water-cooling system requires the following basic items: a water jacket assembly and gaskets, a drain plug to empty the system, a radiator assembly and pressure cap, mounting hardware for the radiator, radiator hoses and clamps, and a non-freezing, anti-corrosive cooling liquid.

In addition, most water-cooling systems employ some or all of the following additional parts: a thermostat; a gear or chain driven water pump; a water temperature gauge, sending unit, and mounting hardware; an electric cooling fan and mounting hardware; and a temperature sensing unit to activate the cooling fan as needed.

Each of these components is prone to failure of one kind or another. Therefore, a water-cooled motorcycle will require additional servicing and repair work. How much additional maintenance and repair work will depend on the skill of the motorcycle manufacturer and the luck of individual owners. The Suzuki water-cooled system shows an attention to detail and a concern for quality previously unknown on production water-cooled motorcycle engines. But the Suzuki people would freely admit that their water-cooling system, like any mechanical device, requires periodic maintenance and the occasional replacement of broken parts.

In addition, the various parts of a water-cooling system add to the initial cost of a motorcycle. The premium for water-cooling will vary, depending on engine size, the number and complexity of the various components, and the additional assembly-line time necessary for installation. But a motorcyclist could reasonably expect to pay an additional $80 to $225 for the privilege of owning a water-cooled motorcycle engine.

Then, too, there is the question of weight. A complete water-cooling system, topped up and ready to go, tips the scales at somewhere on the order of 40 to 50 lb for a large capacity, multi-cylinder engine. In other words, water-cooling adds an additional 10 percent to the unladen weight of a motorcycle. Nearly the entire burden of that weight is carried above the axle and crankshaft centerlines, where it will cause marginally (most riders would not notice the difference) slower and less lively handling.

Finally, there is the esthetic problem. Suzuki and Yamaha have demonstrated the possibility of designing a compact, attractive water-cooling package that harmonizes well with the overall appearance of a motorcycle. Anyone who fears that an effective water-cooling system might have a tacky, bolt-on look should take a second glance at the Suzuki. It still looks like a motorcycle.

A purist, however, would object that any additional components will detract from the stark, functional lines that make a motorcycle so appealing an object to behold. For the man who likes the appearance of open frame spaces and alloy engine finning, the water-cooled engine is one more step down the road toward motorcycles that are no more or less than two-wheeled automobiles.

The weekend trail rider, the enduro or scrambles racer, the boulevard hot dog, cafe racers, and all those motorcyclists who fondly recall the sight and sound of a big Single Norton or Matchless at full song will have little interest in the virtues of water-cooling. For them, water-cooled engines are simply one more step down that road. But water-cooling does offer important and worthwhile advantages for the two-stroke road racer, for practical and long lasting utility bikes, and for quiet, smooth, long distance touring motorcycles. And when—or if—rotary engine motorcycles begin rolling off the assembly lines, you can be sure they will be water-cooled, too. ES

View Full Issue

View Full Issue