THE HUSKY FACTORY

A Swedish Concern That Deals In Precision, But In A Conservative Sort Of Way.

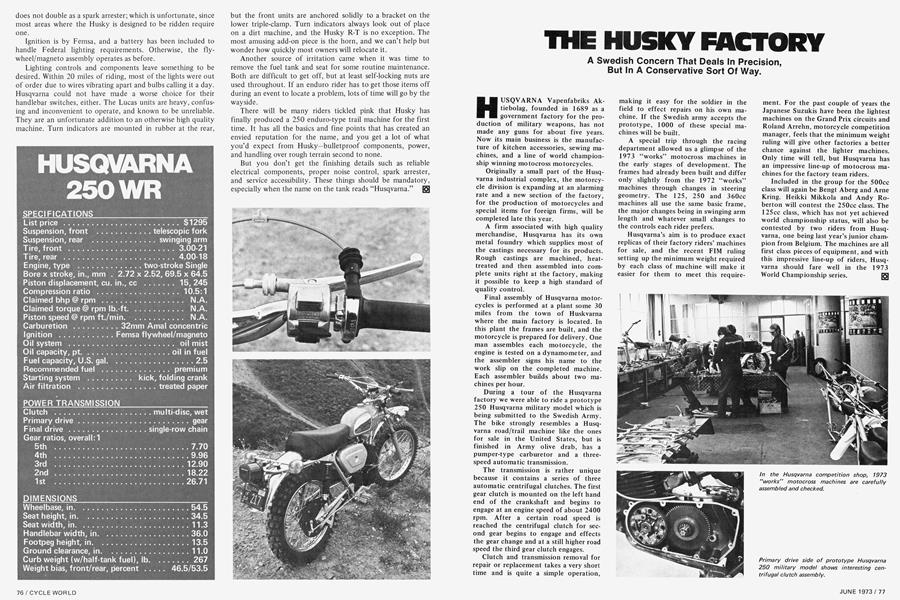

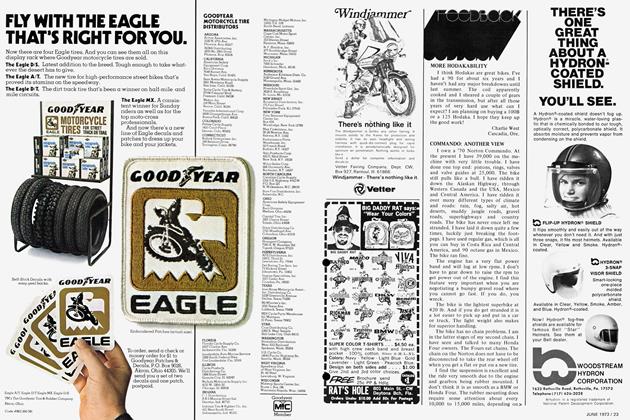

HUSQVARNA Vapenfabriks Aktiebolag, founded in 1689 as a government factory for the production of military weapons, has not made any guns for about five years. Now its main business is the manufacture of kitchen accessories, sewing machines, and a line of world championship winning motocross motorcycles.

Originally a small part of the Husqvarna industrial complex, the motorcycle division is expanding at an alarming rate and a new section of the factory, for the production of motorcycles and special items for foreign firms, will be completed late this year.

A firm associated with high quality merchandise, Husqvarna has its own metal foundry which supplies most of the castings necessary for its products. Rough castings are machined, heattreated and then assembled into complete units right at the factory, making it possible to keep a high standard of quality control.

Final assembly of Husqvarna motorcycles is performed at a plant some 30 miles from the town of Huskvarna where the main factory is located. In this plant the frames are built, and the motorcycle is prepared for delivery. One man assembles each motorcycle, the engine is tested on a dynamometer, and the assembler signs his name to the work slip on the completed machine. Each assembler builds about two machines per hour.

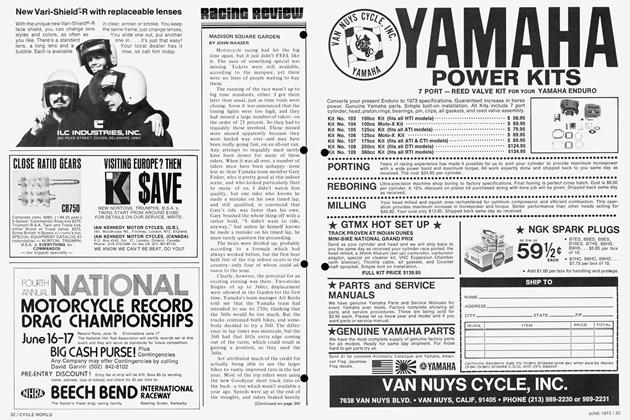

During a tour of the Husqvarna factory we were able to ride a prototype 250 Husqvarna military model which is being submitted to the Swedish Army. The bike strongly resembles a Husqvarna road/trail machine like the ones for sale in the United States, but is finished in Army olive drab, has a pumper-type carburetor and a threespeed automatic transmission.

The transmission is rather unique because it contains a series of three automatic centrifugal clutches. The first gear clutch is mounted on the left hand end of the crankshaft and begins to engage at an engine speed of about 2400 rpm. After a certain road speed is reached the centrifugal clutch for second gear begins to engage and effects the gear change and at a still higher road speed the third gear clutch engages.

Clutch and transmission removal for repair or replacement takes a very short time and is quite a simple operation, making it easy for the soldier in the field to effect repairs on his own machine. If the Swedish army accepts the prototype, 1000 of these special machines will be built.

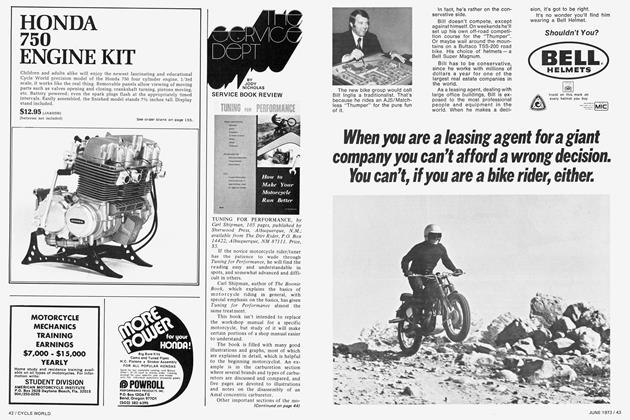

A special trip through the racing department allowed us a glimpse of the 1973 “works” motocross machines in the early stages of development. The frames had already been built and differ only slightly from the 1972 “works” machines through changes in steering geometry. The 125, 250 and 360cc machines all use the same basic frame, the major changes being in swinging arm length and whatever small changes to the controls each rider prefers.

Husqvarna’s aim is to produce exact replicas of their factory riders’ machines for sale, and the recent FIM ruling setting up the minimum weight required by each class of machine will make it easier for them to meet this requirement. For the past couple of years the Japanese Suzukis have been the lightest machines on the Grand Prix circuits and Roland Arrehn, motorcycle competition manager, feels that the minimum weight ruling will give other factories a better chance against the lighter machines. Only time will tell, but Husqvarna has an impressive line-up of motocross machines for the factory team riders.

Included in the group for the 500cc class will again be Bengt Aberg and Arne Kring. Heikki Mikkola and Andy Roberton will contest the 250cc class. The 125cc class, which has not yet achieved world championship status, will also be contested by two riders from Husqvarna, one being last year’s junior champion from Belgium. The machines are all first class pieces of equipment, and with this impressive line-up of riders, Husqvarna should fare well in the 1973 World Championship series.