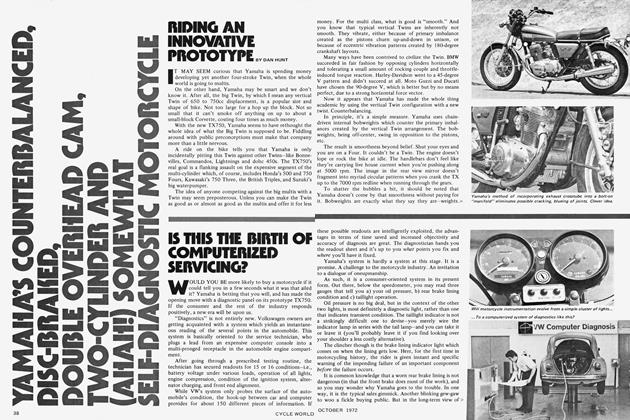

IS THIS THE BIRTH OF COMPUTERIZED SERVICING?

WOULD YOU BE more likely to buy a motorcycle if it could tell you in a few seconds what it was that ailed it? Yamaha is betting that you will, and has made the opening move with a diagnostic panel on its prototype TX750. If the consumer and the rest of the industry responds positively, a new era will be upon us.

“Diagnostics” is not entirely new. Volkswagen owners are getting acquainted with a system which yields an instantaneous reading of the several points in the automobile. This system is basically oriented to the service technician, who plugs a lead from an expensive computer console into a multi-pronged receptacle in the automobile engine compartment.

After going through a prescribed testing routine, the technician has secured readouts for 15 or 16 conditions—i.e., battery voltage under various loads, operation of all lights, engine compression, condition of the ignition system, alternator charging, and front end alignment.

While VW’s system only probes the surface of the automobile’s condition, the hook-up between car and computer provides for about 150 different pieces of information. If these possible readouts are intelligently exploited, the advantages in terms of time saved and increased objectivity and accuracy of diagnosis are great. The diagnostician hands you the readout sheet and it’s up to you what points you fix and where you’ll have it fixed.

Yamaha’s system is hardly a system at this stage. It is a promise. A challenge to the motorcycle industry. An invitation to a dialogue of oneupmanship.

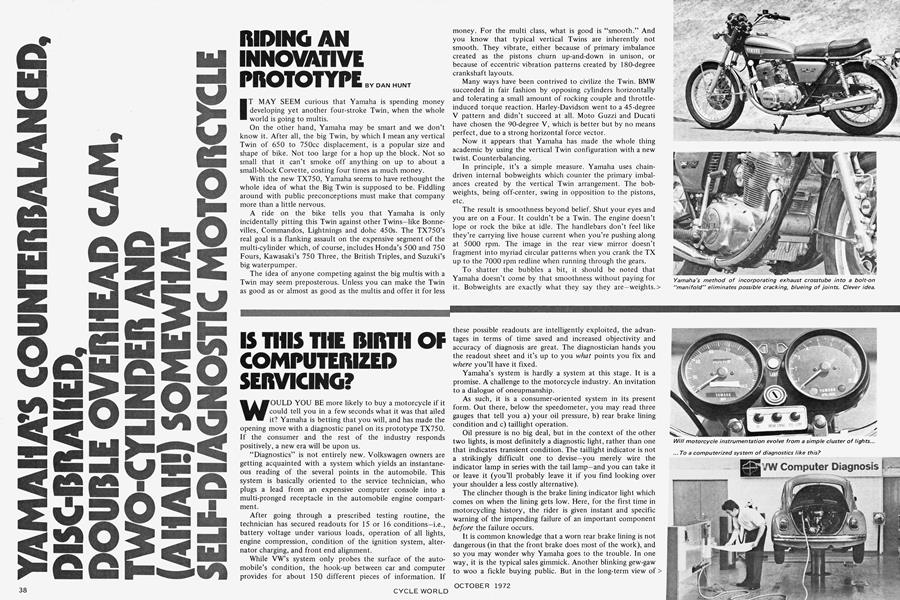

As such, it is a consumer-oriented system in its present form. Out there, below the speedometer, you may read three gauges that tell you a) your oil pressure, b) rear brake lining condition and c) taillight operation.

Oil pressure is no big deal, but in the context of the other two lights, is most definitely a diagnostic light, rather than one that indicates transient condition. The taillight indicator is not a strikingly difficult one to devise—you merely wire the indicator lamp in series with the tail lamp—and you can take it or leave it (you’ll probably leave it if you find looking over your shoulder a less costly alternative).

The clincher though is the brake lining indicator light which comes on when the lining gets low. Here, for the first time in motorcycling history, the rider is given instant and specific warning of the impending failure of an important component before the failure occurs.

It is common knowledge that a worn rear brake lining is not dangerous (in that the front brake does most of the work), and so you may wonder why Yamaha goes to the trouble. In one way, it is the typical sales gimmick. Another blinking gew-gaw to woo a fickle buying public. But in the long-term view of things, that little gimmick is also a market test. To get public reaction you have to put it out on the handlebars where the public can see it.

Ironically, if the brake lining light is successful, in a few years it will disappear into a black box under the seat with several other component status readout junctions. Why? Even though it would be possible to build a 20-item instrument panel on the motorcycle, it would be costly and of dubious benefit to the rider.

The reasons are clear. By reserving the diagnostic readout for the technician’s eyes alone, you keep the motorcycle relatively simple. You also protect the motorcycle from the individual who is overly anxious to make conclusions based upon a complex combination of instrument readouts. And you lower manufacturing cost; complex panels, besides being expensive in themselves, also have extra power and space requirements. By instead offering a junction box which may be joined with an external diagnostic console, you externalize the extra power supply and component needs. The console provides its own power for the tests to be made.

It is amazing how much information may be culled from a mechanical entity by relatively simple means. The Yamaha

brake lining light, for example, consists of a wire running to a contact fixed near the brake shoe actuating cam. When the lining wears down, the cam turns far enough to make electrical contact. The motorcycle frame is used as electrical ground so only one wire is needed to reach the sensor.

The brake lining readout is what may be termed a “yes or no” situation. Yes, the lining is good. No, the lining is not good. Any situation like this offers an extremely simple situation for computer analysis.

If and when Yamaha or other manufacturers get to the external console stage, however, they will want to take more complex measurements. For example, cylinder pressure without the engine firing is one example of a measurement that defies simple “good” or “not good” diagnosis. It is rather an acceptable range of cylinder pressure which must be subjectively interpreted before you can flatly declare that the patient needs a valve job.

If you hand test a cylinder, you are in effect taking an analog, or progressively quantitative, reading which is not diagnostic in itself. You are functioning as part of the instrument to make the diagnosis. Your mind is programmed by the shop manual. It tells you that the reading will be 125 to 150 psi. Below 125 psi, something’s really wrong. Readout: valve job.

If, instead, you mechanize this whole process, you must invent a diagnostic instrument which works essentially as a simple computer. The sensor gives a continuous reading along the scale from 125 to 150 psi. An electronic device known as a comparator converts the reading to a piece or “bit” of warning information only if the psi drops below the lower acceptable limit. Readout: valve job. If no readout at all: wait and we’ll run it through the machine again at the next maintenance period.

In eliminating the progressive reading, you preclude the astute borderline diagnoses possible for a clever mechanic. However, it is debatable how useful a clever mechanic is. If he tells you that your cylinder pressure was 127 psi and although the bike is running okay now, you’ll need a valve job in 3000 miles, is he really telling you anything you are going to act upon? I doubt it, unless of course you are an absolute perfectionist. Like most people, you’ll let it slide for several weeks until you absolutely need it.

Much better for most people that they receive a cut and dried absolutist shmear from a computer for a ten-dollar bill than a terse, secretive check from a disinterested tune-up man at two or three times the price.

Indeed, when the inputs to the computer console reach a certain number, the console may be programmed to deliver quite sophisticated gradations of advice to the machine owner. For instance, combine comparator interpretations of dwell angle, plug voltage and fuel mixture to deduce the extent and cost of a proposed tune-up.

The major expense to the consumer is the inclusion of all these sensing devices on the motorcycle. Whether or not it is worthwhile depends on several things: Cost of installation versus cost of the machine to be sold. Type of machine: Is it the sort of bike that is primarily owner-maintained? Number of miles that a machine like this is ridden: If the annual mileage figure is low, then there is not much value in an electric sensor readout for long-term maintenance items.

The choice of items to be measured must be made carefully. Furthermore, it is extremely important that there be a consensus among manufacturers on what constitutes a proper plug-in diagnostic system. Having each manufacturer develop his own system with total disregard for the others is to invite chaos in the service industry and resentment at both the rider and dealer level.

The introduction of the VW system to the automobile world has posed the same problem, which was the subject of a recent national meeting of engineers and government agency people in San Francisco. By encouraging a cross-breeding and exchange of ideas the government hopes to extract the maximum possible benefit from this new science.

The benefit is there, to be sure, for all you have to do is figure how much labor it would cost you to have a Yamaha mechanic dismount your rear wheel and check the brake lining. The labor charge would just about cover the cost of materials used for Yamaha’s new sensor.

To me, that’s progress.