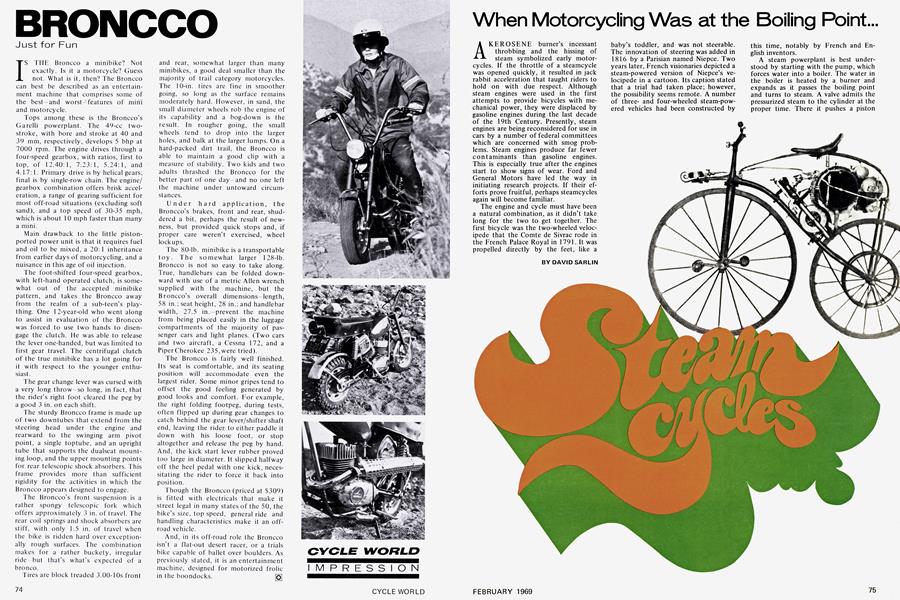

Steam cycles

When Motorcycling Was at the Boiling Point...

DAVID SARLIN

AKEROSENE burner's incessant throbbing and the hissing of steam symbolized early motorcycles. If the throttle of a steamcycle was opened quickly, it resulted in jack rabbit acceleration that taught riders to hold on with due respect. Although steam engines were used in the first attempts to provide bicycles with mechanical power, they were displaced by gasoline engines during the last decade of the 19th Century. Presently, steam engines are being reconsidered for use in cars by a number of federal committees which are concerned with smog problems. Steam engines produce far fewer contaminants than gasoline engines. This is especially true after the engines start to show signs of wear. Ford and General Motors have led the way in initiating research projects. If their efforts prove fruitful, perhaps steamcycles again will become familiar.

The engine and cycle must have been a natural combination, as it didn't take long for the two to get together. The first bicycle was the two-wheeled veloc ipede that the Comte de Sivrac rode in the French Palace Royal in 1791. It was propelled directly by the feet, like a

baby’s toddler, and was not steerable. The innovation of steering was added in 1816 by a Parisian named Niepce. Two years later, French visionaries depicted a steam-powered version of Niepce’s velocipede in a cartoon. Its caption stated that a trial had taken place; however, the possibility seems remote. A number of threeand four-wheeled steam-powered vehicles had been constructed by

this time, notably by French and English inventors.

A steam powerplant is best understood by starting with the pump, which forces water into a boiler. The water in the boiler is heated by a burner and expands as it passes the boiling point and turns to steam. A valve admits the pressurized steam to the cylinder at the proper time. There it pushes a piston

downward, and is exhausted when its work is completed. To conserve water, steam is sometimes condensed in a unit that looks and works like a car radiator.

In 1839, a Scottish blacksmith, Kirkpatric MacMillan, added a treadle-like arrangement that drove the rear wheels through connecting rods. Pedals were first added directly to the front wheels in 1861 by the Michaux Co. of Paris. This firm placed France in the forefront of bicycle development with addition of a single-cylinder steam engine (manufactured by Perreaux) to a bicycle in 1869. The kerosene fired boiler was located under the seat, along with the engine, which drove the rear wheel through a belt. The engine was double-actingsteam pushed the piston both upward and downward. This steam bicycle never was produced commercially; however, the wrought iron framed pedal bicycle became well known under the descriptive name of “boneshaker.”

The initial American steamcycle was completed the same year by Sylvester Roper, of Roxbury, Mass., who built approximately 10 steam-powered vehicles during his lifetime. His first machine wasdriven over 2000 miles. A handbill of the day stated; “This triumph in mechanism can be driven up any hill and outspeed any horse.” Steam was provided by a firetube boiler—with water and steam contained in a vessel with tubes, through which hot gases passed. A two-cylinder, 2.5-in. bore, 5-in. stroke, piston-valve engine was directly connected to the rear axle. Both of the iron-banded, woodenspoked wheels were 34 in. in diameter. Charcoal, kept handy on the rider’s lap, was used for fuel. Water, stored in a tank (which also doubled as a saddle) was fed to the boiler from a crankdriven pump. With such a system, water is fed more or less according to demand. Twisting the handlebar one way opened the throttle, and twisting it the other way applied the front brake. This ingenious arrangement was probably necessary to allow the rider freedom to pay attention to the duties of fireman and engineer.

In addition to being abused and threatened with personal violence, Roper was arrested many times for frightening people and horses. There was no law against his actions, so he was always released—until such an ordinance was pushed through by frightened city councilmen. Progress easily prevailed, and the ordinance was repealed when it was discovered that a short time before, the council had appropriated $5000 for the development of a self-propelled steam fire engine. The Michaux and Roper steam powered velocipedes (constructed in 1869) are the earliest known surviving ancestors of contemporary motorcycles.

In 1875, the Highflyer was tested in London, but it seems doubtful that it was either a technical or a commercial success. It was driven by what is known as an oscillating engine. One cylinder was located on the inside of each leg of the fork of its large front wheel. A copper boiler, fired by a small kerosene burner, was mounted above the two small rear wheels of this unique tricycle.

After experimenting with a highwheel Columbia bicycle, Lucius Copeland successfully mounted a steam engine in a Star bicycle in 1884. Observers of the day commented that when the throttle was opened, the unit moved silently and swiftly with no smoke or escaping steam visible. The 10-in. diameter boiler was 6 in. high and had 14.5-in. droptubes, 10 in. long, extending from the bottom. It was heated by a gasoline burner, and a one-pint fuel tank was sufficient for an hour’s drive. A spherical water tank held enough for a similar distance, including water that was condensed in the process of preheating the fuel. The single-cylinder engine had a 1.062-in. diameter bore, and a 3-in. stroke. At 100 psi, 0.5 bhp was developed. This was sufficient to drive the machine at speeds up to 12 mph.

Probably few riders went that fast, because the high seat (above a 51-in. rear wheel) made it difficult to keep the cycle from tipping over. A belt drive provided a 9:1 reduction, so that the engine turned only 712 rpm at top speed. The whole unit was very light and added only 18 lb. to the weight of the bicycle. The Star bicycle was supposed to be safer than others, because the rider’s weight was slightly forward of the rear axle. This arrangement necessitated using levered pedals, which drove the wheel by a ratchet mechanism. It had the advantage of allowing the rider to press down on both pedals at once.

Efforts to manufacture the machine brought Copeland from Arizona to California and then to New York. He manufactured approximately 200 tricycle versions under the name of Northrop Manufacturing Co., and then, in 1888, produced a steamcycle version of the common safety bicycle. A balance wheel was added and the first sidecar came into existence when a seat was mounted on its support bracket. Even though his machine appeared to operate satisfactorily, the public was not ready to accept such a novel method of transportation.

The first German steamcycle was built by the Hildebrand brothers, of Munich, in 1889. The cycle is also known as the Dalifol, from the name of a Frenchman who copied the Hildebrand design. The flash steam-generator it used was developed in France by Serpollet. This component acquired its name for the rapidity with which it made steam. A throttle controlled the water as it entered a coke-fired steamgenerator, from which it went freely to the engine as high pressure steam. Feeding coke down the chute directly in front of the seat must have encouraged riders to wear dark trousers. Directly connected to the crankshaft was a pump

that fed water to the steam generator from a tank (which doubled as a rear fender). A single-cylinder 1.875-in. bore, 5-in. stroke, slide valve engine was directly connected to the rear wheel. This steamcycle weighed a modest 155 lb., and displayed such features as front and rear wheel brakes, an engine lubrication system, and a spacious toolbox mounted on the handlebars. It was supposed to have achieved a speed of 25 mph, and participated in a race in England in 1896. The rapid development of the gasoline engine during this era encouraged the brothers to develop a water cooled, two-cylinder gasoline engined cycle. It was produced in 1894 and 1895 under the name of Hildebrand and Wolf muller, and would have been more popular if the engine’s connecting rods had not been connected directly to the rear axle. This arrangement undoubtedly caused some unique problems when starting and stopping.

Sylvester Roper, previously mentioned, completed his last steamcycle in 1896 at age 72. This time he used a water tube boiler, in which a coal fire heated water contained in tubes that were attached to a vessel. At 185 psi, his single-cylinder engine developed 8 bhp. During the first trial at Dorchester, Mass., it attained a speed of 40 mph. Several days later, he left competing bicyclists far behind in a cloud of soot and steam during the first 1-mile lap around a bicycle track. As he started for a second lap, he faltered and crashed. It was decided that he died of a heart attack; probably quite content to see his life ambition fulfilled.

Little interest was shown in external combustion cycles after the first commercial development of internal combustion cycles. Compared to early internal combustion cycles, steamcycles had the advantages of being smooth, silent, and free from annoying troubles with cooling and ignition systems. Inherently high torque at low speeds eliminated the need for shifting gears. However, the gasoline burner (a roaring inferno nes-

tied under the seat) didn’t soothe rider’s worries of a sideslip-a common occurence with the tires of the day. If coal was used, it had to be fed at the proper rate-a dirty job requiring a fair amount of attention. The control system was entirely in the hands of the operator, who had to constantly adjust the firing and feed water rates to suit the everchanging driving conditions. As one rider noted, “The rise in steam pressure on a sudden stop didn’t make one feel at ease.”

The period of great growth in the motorcycle industry (1910-1920) saw the last commercially-produced steamcycle. Between 1912 and 1914, Pearson-Cox, Ltd., England, sold quite a number of steamcycles that were based on the design of the Serpollet steam car. The company was sold in 1914, but because of the war, the new owner unfortunately never started production on this most successful steamcycle. A vaporizing burner, like that of the Stanley steam car, was used to fire a flash steam generator, which utilized 65 ft. of heavy gauge steel tubing. It operated at 800 F and at a pressure of 100-500 psi. A single-acting, single-cylinder, 1.75-in. bore, 2-in. stroke engine had cam-driven poppet valves and developed 6.5 bhp. Poppet valves are not widely used on steam engines, but are mandatory for successful operation with high pressure steam. The chain drive to the rear wheel provided a 3.5:1 ratio. Sufficient water was carried for 40 miles and it was fed to the steam generator by a crankshaft driven pump. Two controls were used-

one bypassing a portion of the water intended for the steam generator (so as to limit engine speed) and the other bypassing it all for stopping. The top speed of this 145-lb. machine was about 45 mph and it was said to be a good hill climber.

Niles Gillenwaters, of Sacramento, Calif., completed a steamcycle in 1918 after six years of work. He claimed to have once driven it at the phenominal speed of 1 10 mph. It also was supposed to have traveled more than 75 miles without needing to stop for fuel or water. A two-speed Eclipse chain drive was later installed to make the machine more suitable for town driving.

The French government once wanted to buy the machine, but did not offer enough money. In 1920, Gillenwaters sold it to the San Francisco Cliff House Museum, where a sign advertised that it had been driven more than 17,000 miles. Once a week, for a number of years, the cycle was fired up. The proverbial “steam story” persists, that a reward was offered to anybody who would drive it wide open for 2 min.

The engine was of the uniflow type, in which steam flowed only in one direction in the cylinder. Steam was admitted to the cylinder through a poppet valve and exhausted through ports in the cylinder wall. Its three single-acting cylinders had a 1.75-in. diameter bore and a 2.25-in. stroke. A sliding camshaft enabled steam to be admitted for only one-quarter stroke, for economy; full stroke, for power; and at the other end of the piston, for reverse (handy with a sidecar). Steam was provided by a 500 psi, 600 F watertube boiler, with two drums connected by 180 tubes. The water, fuel, and lubricator pumps were directly connected to the engine, but a hand pump was needed when making a cold start. The control system was adapted from a Stanley steam car. A Thor two-cylinder internal combustion engined motorcycle (which partially survived an accident with a streetcar) provided the frame. The cycle now is being restored by its present owner in San Francisco, Calif.

William Taylor used an FN four-cylinder internal combustion motorcycle for his steamcycle. It had a fire-tube boiler, 9 in. in diameter and 10 in. high, with 120 tubes of 0.5 in. diameter, and was fired by a kerosene burner. A 2-in. bore, 2.5-in. stroke single-cylinder engine

drove the rear wheel through a 6.5:1 bevel gear reduction. Part of the steam was condensed in heating the feed water, but, according to a motorcycle test-rider, the machine still suffered from a limited water-carrying capacity.

A well detailed design for a steamcycle appeared in a 1918 issue of The Model Engineer and Electrician. The proposed two-cylinder engine featured poppet valves and a sliding camshaft. Steam was produced by a flash steamgenerator similar to that used in the Pearson-Cox cycle. Calculations indir cated that this condensing cycle could be driven 100 miles without needing to stop for fuel or water. A cycle was built according to this design, but it is not known how successful it was.

Plans were made in the 1920s to form a company to manufacture a steamcycle designed by Bud Langford, of Denver, Colo. His cycle’s two-cylinder piston valve engine had a bore of 3 in., a stroke of 2.5 in., and was directly connected to the rear wheel. It only took a few minutes to generate steam, and a speed of 60 mph could be reached in only 60 ft. This data should be interpreted with care, because a boiler’s storage capacity for quick starts doesn’t indicate what its continuous steaming rate is. All the controls were claimed to have been automated and it made 35 mpg of gasoline.

In 1923, James Sadler, a steamcycle enthusiast from Glasgow, Scotland, finished his first cycle. He started with an Indian frame and used a watertube boiler and a compound engine; in which steam exhausted from one cylinder was admitted to a second larger cylinder. This type of engine is advantageous when superheated steam is used, but is rarely utilized with widely variable loads. His next machine had a flash boiler and a two-cylinder, single-acting engine. Sadler had a great deal of difficulty obtaining insurance for these

machines, but after a good deal of negotiation, he was able to obtain coverage for his fourth machine. It incorporated a sidecar and a firetube boiler. Because many steamcycles have a high center of gravity, a sidecar must have been desirable for stability. There is little doubt that a rider would encounter enough adventure, without adding the fear of falling under a heavy machine with high pressure steam pipes, pressurized fuel lines, and hissing flames.

. Sadler’s last, and most well known. 1934 machine, had a two-cylinder engine and a water-tube boiler. The water pump had a separate engine. He realized that this engine wasted steam, but he didn’t remove it because it proved so fascinating to bystanders. The cycle delivered 18 mpg of fuel, but less than 2 mpg of water. Once, during a stop for water and refreshments, some onlookers put beer in his water tank. As he left, he gave a hearty blast of his whistle, and rode off with the unit operating just as it had when he arrived. Shortly after he was out of sight, the unit started to slow down. He suspected something was wrong and when he saw a big head of foam in the boiler water-level glass, he quickly realized why everyone was smiling at the last stop. Sadler used the cycle regularly, but dismantled it at the outbreak of the war.

In the recent past, a bicycle-type, one-cylinder steam engine, with a water-tube boiler, was sold by Anton Bohaboy, of Rahway, N. J. Rumor has it that his 20 mph trips through the countryside turned many a fence post into a plume of smoke'. Recently, most hobbyists have used old steam automobile engines to power their steam motorcycles. During the 1940s, John Barr, of Middletown, Ohio, used a 250 psi monotube steam generator with an 1 898 Stanley steam car engine to drive a cycle at 45 mph.

To date, the most efficient steam powered two-wheelers have been limited by a practical, optimum water-mileage rate of 10 mpg. Thus, for a 100-mile touring radius, at least 83 lb. of water would have to be carried by a non-condensing cycle.

Most steamcycles resulted from individual efforts and did not incorporate the features of other builders. Utilizing modern technology, a feasible steampowered motorcycle could be built that would be durable, silent and easy to operate. There would be no need to shift gears, and it would be capable of high speeds and acceleration rates.

The Thermo Electron Corp. has developed a small, self-contained, steam electric-generator for the army. Ford Motor Co. has joined this firm, and is spending $1 million to develop small steam engine units for low power applications, such as golf carts and outboard motors. If their project is successful, it is highly probable that new efforts will be made to develop a steamcycle. In any case, the cult of steam motorcycle enthusiasts will no doubt continue to be fascinated by the potential of steam, and the challenge of reducing an inherently bulky power source into a relatively small space.