COOL IT!

Compact Coils for a Hot Climate

ROBERT O. FEE

IT'S HOT!! The sun hammers down with a malicious fury, and waves of heat from the sizzling pavement strike like physical blows. The Chamber of Commerce says the temperature is only 112 degrees, but that's in the shade and there's no shade in sight. Is this a scene from the Sahara Desert? Not at all-it's just a typical summer day in the great southwestern desert of the United States. Extreme conditions such as these make oil run like water and the idiot lamp winks a bright red when the engine idles.

“But a motorcycle engine is air cooled,” some will say.

This is a valid point when speaking of the smaller trail bikes, but not entirely so with the large road machines sucn as the Harley-Davidson 74-cu. in. Electra Glide and some foreign makes. The factory separated the oil tank from the engine for a very good reason; the entire lower end depends primarily on oil to gather heat from the crank, rods, and other important bearings.

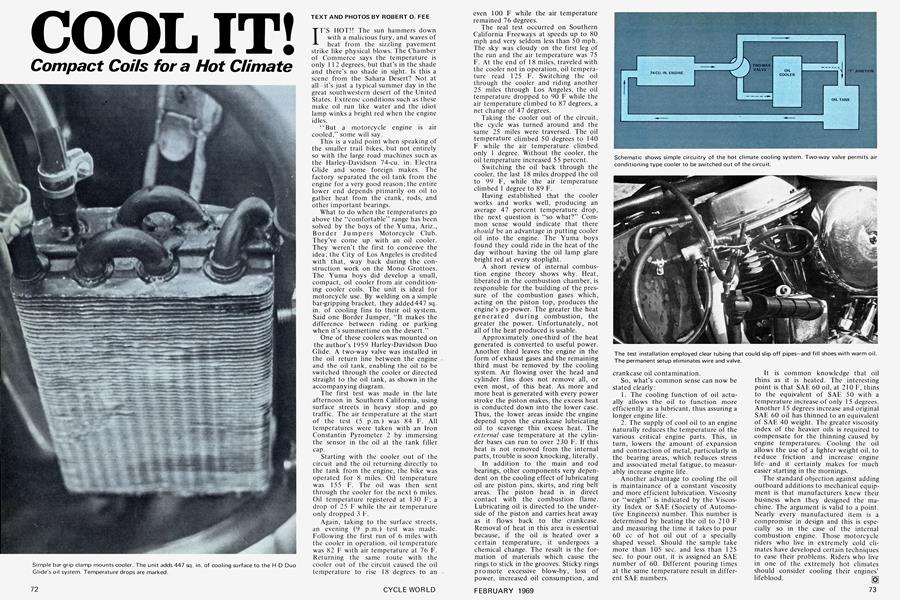

What to do when the temperatures go above the “comfortable” range has been solved by the boys of the Yuma, Ariz., Border Jumpers Motorcycle Club. They’ve come up with an oil cooler. They weren’t the first to conceive the idea; the City of Los Angeles is credited with that, way back during the construction work on the Mono Grottoes. The Yuma boys did develop a small, compact, oil cooler from air conditioning cooler coils. The unit is ideal for motorcycle use. By welding on a simple bar-gripping bracket, they added447 sq. in. of cooling fins to their oil system. Said one Border Jumper, “It makes the difference between riding or parking when it’s summertime on the desert.” One of these coolers was mounted on the author’s 1959 Harley-Davidson Duo Glide. A two-way valve was installed in the oil return line between the engine and the oil tank, enabling the oil to be switched through the cooler or directed straight to the oil tank, as shown in the accompanying diagram.

The first test was made in the late afternoon in Southern California, using surface streets in heavy stop and go traffic. The air temperature at the start of the test (5 p.m.) was 84 F. All temperatures were taken with an Iron Constantin Pyrometer 2 by immersing the sensor in the oil at the tank filler cap.

Starting with the cooler out of the circuit and the oil returning directly to the tank from the engine, the bike was operated for 8 miles. Oil temperature was 155 F. The oil was then sent through the cooler for the next 6 miles. Oil temperature registered at 130 F; a drop of 25 F while the air temperature only dropped 3 F.

Again, taking to the surface streets, an evening (9 p.m.) test was made. Following the first run of 6 miles with the cooler in operation, oil temperature was 82 F with air temperature at 76 F. Returning the same route with the cooler out of the circuit caused the oil temperature to rise 18 degrees to an even 100 F while the air temperature remained 76 degrees.

The real test occurred on Southern California Freeways at speeds up to 80 mph and very seldom less than 50 mph. The sky was cloudy on the first leg of the run and the air temperature was 75 F. At the end of 18 miles, traveled with the cooler not in operation, oil temperature read 125 F. Switching the oil through the cooler and riding another 25 miles through Fos Angeles, the oil temperature dropped to 90 F while the air temperature climbed to 87 degrees, a net change of 47 degrees.

Taking the cooler out of the circuit, the cycle was turned around and the same 25 miles were traversed. The oil temperature climbed 50 degrees to 140 F while the air temperature climbed only 1 degree. Without the cooler, the oil temperature increased 55 percent.

Switching the oil back through the cooler, the last 18 miles dropped the oil to 99 F, while the air temperature climbed 1 degree to 89 F.

Having established that the cooler works and works well, producing an average 47 percent temperature drop, the next question is “so what?” Common sense would indicate that there should be an advantage in putting cooler oil into the engine. The Yuma boys found they could ride in the heat of the day without having the oil lamp glare bright red at every stoplight.

A short review of internal combustion engine theory shows why. Heat, liberated in the combustion chamber, is responsible for the building of the pressure of the combustion gases which, acting on the piston top, produces the engine’s go-power. The greater the heat generated during combustion, the greater the power. Unfortunately, not all of the heat produced is usable.

Approximately one-third of the heat generated is converted to useful power. Another third leaves the engine in the form of exhaust gases and the remaining third must be removed by the cooling system. Air flowing over the head and cylinder fins does not remove all, or even most, of this heat. As more and more heat is generated with every power stroke the piston makes, the excess heat is conducted down into the lower case. Thus, the lower areas inside the engine depend upon the crankcase lubricating oil to scavenge this excess heat. The external case temperature at the cylinder bases can run to over 230 F. If this heat is not removed from the internal parts, trouble is soon knocking, literally.

In addition to the main and rod bearings, other components very dependent on the cooling effect of lubricating oil are piston pins, skirts, and ring belt areas. The piston head is in direct contact with the combustion flame. Lubricating oil is directed to the underside of the piston and carries heat away as it flows back to the crankcase. Removal of heat in this area is essential because, if the oil is heated over a certain temperature, it undergoes a chemical change. The result is the formation of materials which cause the rings to stick in the grooves. Sticky rings promote excessive blow-by, loss of power, increased oil consumption, and crankcase oil contamination.

So, what’s common sense can now be stated clearly:

1. The cooling function of oil actually allows the oil to function more efficiently as a lubricant, thus assuring a longer engine life.

2. The supply of cool oil to an engine naturally reduces the temperature of the various critical engine parts. This, in turn, lowers the amount of expansion and contraction of metal, particularly in the bearing areas, which reduces stress and associated metal fatigue, to measurably increase engine life.

Another advantage to cooling the oil is maintainance of a constant viscosity and more efficient lubrication. Viscosity or “weight’’ is indicated by the Viscosity Index or SAE (Society of Automotive Engineers) number. This number is determined by heating the oil to 210 F and measuring the time it takes to pour 60 cc of hot oil out of a specially shaped vessel. Should the sample take more than 105 sec. and less than 125 sec. to pour out, it is assigned an SAE number of 60. Different pouring times at the same temperature result in different SAE numbers.

It is common knowledge that oil thins as it is heated. The interesting point is that SAE 60 oil, at 210 F, thins to the equivalent of SAE 50 with a temperature increase of only 1 5 degrees. Another 1 5 degrees increase and original SAE 60 oil has thinned to an equivalent of SAE 40 weight. The greater viscosity index of the heavier oils is required to compensate for the thinning caused by engine temperatures. Cooling the oil allows the use of a lighter weight oil, to reduce friction and increase engine lifeand it certainly makes for much easier starting in the mornings.

The standard objection against adding outboard additions to mechanical equipment is that manufacturers knew their business when they designed the machine. The argument is valid to a point. Nearly every manufactured item is a compromise in design and this is especially so in the case of the internal combustion engine. Those motorcycle riders who live in extremely cold climates have developed certain techniques to ease their problems. Riders who live in one of the extremely hot climates should consider cooling their engines’ lifeblood.