THE SERVICE DEPARTMENT

JOHN DUNN

MR. CLEAN

I own a Hodaka 100 which runs fine. It has an expansion chamber on it, which is great, except for one thing. It is impossible to clean. I have tried sticking brushes down it, but the carbon inside still won 't come out. I have some friends who have the same problem, and we would appreciate any information On how to remove the carbon.

Bill Modesitt

Pacific Palisades, calif.

The most effective method for clean ing a non-detachable muffler or expan sion chamber is to soak the complete unit in a strong solution of caustic soda. Leave it to soak for several hours, then thoroughly hose it off with water. It may be necessary to carry out this procedure several times, if the compo nent is heavily caked with carbon. Other cycle and engine parts also can be thoroughly cleaned in this way, provid ing they are made from a ferrous mate na!. Non-ferrous materials, such as alu minum, should never be cleaned with caustic soda because they will he severe ly damaged. Also, be careful not to get the solution on your skin, clothes, or in your eyes.

FLASH

I keep reading that the new BSAs and Iriumphs arc' "strobe light" timed. I'm referring to statements such as: "With the rise in horsepower, ignition timing became more critical. In 1 968, Triumph in troduced an ignition system that could he set wit/i a strobe light. And you can `t set the ignition much closer than that. " Okay, what is a strobe light, and how is it used?

Ben Bowman

Port Jngeles, Wash.

A `strobe light" (also called a timing light) is an electrical means of setting or checking the ignition timing while the engine is running. It is also used for checking the function of the automatic ignition advance mechanism. The strobe light employs the stroboscope principle, which allows a moving body to be visible only at certain positions during its motion. In other words it is capable of visually stopping a moving object at a certain point (the object will appear to be stationary). The strobe light achieves this by flashing on and off. When the light flashes on for an instant, the moving object will appear stationary for a moment. If the light flashes at regular intervals the object or part of it will appear not to move.

In the case of the engine timing strobe light, the flash is triggered by the high voltage of the spark plug wire. Every time the spark plug fires, the light flashes. If the end of the crankshaft is provided with a small degree wheel and tdc is identified by a stationary pointer, the pointer will indicate the time of ignition when the light flashes. With the engine idling, the actual initial timing will be indicated and, as the engine speed is increased, the automatic ad vance will come into operation, showing a progressively advancing ignition point until maximum ignition advance is achieved. On multi-cylinder engines, the ignition timing can be checked and reset on each individual cylinder. To sum up this explanation, the following takes place: As the spark plug fires, the light flashes onto the degree wheel, visually stopping the wheel, which in turn pre cisely indicates the point of ignition in crankshaft degrees.

Continued on page 14

Continued from 12

THE WHY OF Y

I have a 1967 Bultaco Pursang fivespeed that I have converted to total loss battery ignition. I could not use the standard Bultaco coil, so I used an Autolite 12-V car coil and a 12-V Suzuki X-6 battery. Below is a diagram of the way I have wired it.

This arrangement works fine. Now for my question: I would like to use a twin plug head with both spark plugs firing at the same time. I would use two coils. I would then have to splice into the wire that goes from the points to the negative pole on the coil and make a Y with one wire going to each coil in turn, firing both plugs at the same time. Will this work?

Steve Roberts

Newcastle, WYO.

The twin coil design described by you would work. This method would, how ever, double the load on the contact breaker points and reduce their life considerably. It also would double the demand from the battery, and dras tically cut down the operating time with the total loss system. It would not be necessary to splice any of the wires, just connect the positive pole on one coil to the positive on the other, and connect the coil negatives together also.

A better way of doing this would be by use of a Honda CL 160 12-V twin lead coil. If such is not obtainable, then use either a Honda C72 or C77 12-V twin lead coil. Both types will be more efficient than the two Autolite compo nents. The CL 160 would only be more desirable when compared with the C72 or C77 because it is smaller and lighter.

Continued on page 18

Continued from page 14

UPTIGHT ENFIELD

I have a carburetion problem. The bike is a '6 7 Royal Enfield with twin monoblocs which refuse to idle at less than 2000-2500 rpm with the slides all the way down.

Placing the needles in the number 3 position will give a good idle, but adversely affects acceleration; in the number 4 position, acceleration is good, but idling is too fast. Idling jets require two full turns for good gasoline response which indicates a 25-cc size according to the mechanic `s handbook.

Vincent March ese

Brooklyn, N. Y.

An erratic,excessively high speed idle could be caused by one or more of the following malfunctions.

I. The throttle cables should be adjusted to allow a minimum of backlash. They should be routed in such a way that the throttles do not open or move when the handlebar is turned. With the throttle stops backed off and the throttles fully closed, the engine should be incapable of running. If the engine will run with the throttles fully closed, there may be a massive air leak at the carburetor flange. A quick check for leakage at this point is to squirt oil on the joint with the engine running. An excessively worn throttle slide would result in a similar problem. If everything is in order, screw the throttle stop screws in so they lift the throttle slides sufficiently to allow a moderate idle speed. The screws should be evenly adjusted so that both cylinders pull evenly. Then adjust the throttle cablesso that both slides begin to open at the same time, when the throttle is opened, remembering to leave a small amount of slack in the cables. When the throttle is shut, the throttle stops should position the throttle slides, not the cable adjustment.

2. Idle mixture strength is determined by the idle fuel jet size and idle airscrew adjustment. Screwing the air-adjusting screw in produces a rich idle mixture. Screwing it out weakens the idle mixture. To adjust the idle mixture, screw the air screw in until the engine speed decreases and the engine runs roughly, then back the screw out slightly until the engine idle just smooths out. If the idle speed is too high, it can be decreased by slight adjustment of the throttle stop screws. (Screw out to reduce speed.)

3. Another possible cause of erratic low speed operation is excessively worn inlet valve guides. To check their condition, run the engine at a fast idle with the valve covers removed. Any increase in engine speed, due to air being sucked down the valve guides, can be checked by squirting oil over the valve stem and guide. If there is a great reduction in engine speed, this will definitely indicate worn valve guides.

4. Altering the throttle needle position should not affect the idle mixture, unless there is something drastically wrong elsewhere.

5. When the carburetor is dismantled for cleaning and checking purposes, remove the jet block and check that there is a sealing washer underneath it. If this were missing, idle adjustment, in particular, would be practically impossible.

6. Check that the float is not punctured, that it is installed correctly and that the float spindle bushing is inserted towards the outside (after the float has been inserted).

7. The idle fuel jet is equipped with an extremely small hole and is very susceptible to blockage. Check that it is clear and has not previously been damaged during a cleaning operation. Check that all carburetor passages and drill ways are free from blockage.

8. If the carburetor tends to spit back

when the throttle is opened slightly, this would indicate a lean throttle cut-away condition. A smaller cut-away will result in a richer mixture at this point. If you experience this problem after a good idle has been obtained, it would be worth trying 389/3 throttle slides.

View Full Issue

View Full Issue

More From This Issue

-

Round Up

Round UpRound Up

May 1969 By Joe Parkhurst -

Letters

LettersLetters

May 1969 -

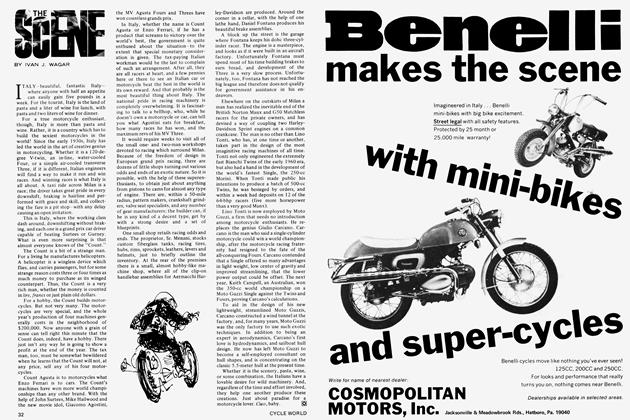

The Scene

The SceneThe Scene

May 1969 By Ivan J. Wagar -

Travel

TravelSpecial Report: the Moving Forces Behind Motorcycle Legislation

May 1969 By J. Bradley Flippin -

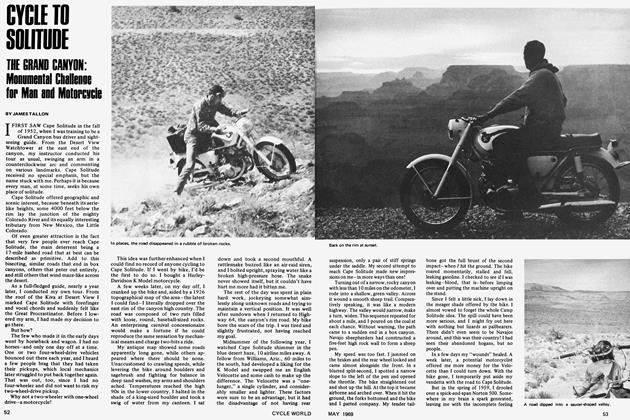

Travel

TravelCycle To Solitude

May 1969 By James Tallon -

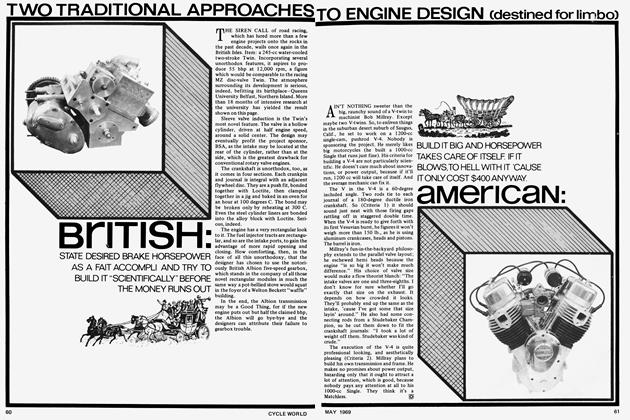

Development

DevelopmentTwo Traditional Approaches To Engine Design (destined For Limbo)

May 1969