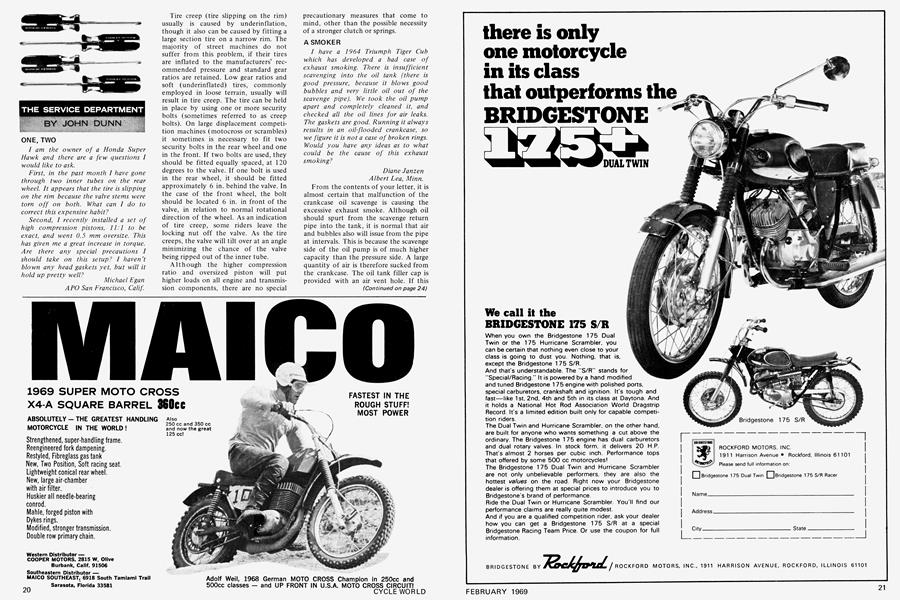

THE SERVICE DEPARTMENT

JOHN DUNN

ONE, TWO

I am the owner of a Honda Super Hawk and there are a few questions I would like to ask.

First, in the past month I have gone through two inner tubes on the rear wheel. It appears that the tire is slipping on the rim because the valve stems were torn off on both. What can I do to correct this expensive habit?

Second, I recently installed a set of high compression pistons, 11:1 to be exact, and went 0.5 mm oversize. This has given me a great increase in torque. Are there any special precautions I should take on this setup? I haven’t blown any head gaskets yet, but will it hold up pretty well?

Michael Egan APO San Francisco, Calif

Tire creep (tire slipping on the rim) usually is caused by underinflation, though it also can be caused by fitting a large section tire on a narrow rim. The majority of street machines do not suffer from this problem, if their tires are inflated to the manufacturers’ recommended pressure and standard gear ratios are retained. Low gear ratios and soft (underinflated) tires, commonly employed in loose terrain, usually will result in tire creep. The tire can be held in place by using one or more security bolts (sometimes referred to as creep bolts). On large displacement competition machines (motocross or scrambles) it sometimes is necessary to fit two security bolts in the rear wheel and one in the front. If two bolts are used, they should be fitted equally spaced, at 120 degrees to the valve. If one bolt is used in the rear wheel, it should be fitted approximately 6 in. behind the valve. In the case of the front wheel, the bolt should be located 6 in. in front of the valve, in relation to normal rotational direction of the wheel. As an indication of tire creep, some riders leave the locking nut off the valve. As the tire creeps, the valve will tilt over at an angle minimizing the chance of the valve being ripped out of the inner tube.

Although the higher compression ratio and oversized piston will put higher loads on all engine and transmission components, there are no special

precautionary measures that come to mind, other than the possible necessity of a stronger clutch or springs.

A SMOKER

I have a 1964 Triumph Tiger Cub which has developed a bad case of exhaust smoking. There is insufficient scavenging into the oil tank (there is good pressure, because it blows good bubbles and very little oil out of the scavenge pipe). We took the oil pump apart and completely cleaned it, and checked all the oil lines for air leaks. The gaskets are good. Running it always results in an oil-flooded crankcase, so we figure it is not a case of broken rings. Would you have any ideas as to what could be the cause of this exhaust smoking?

Diane Janzen Albert Lea, Minn.

From the contents of your letter, it is almost certain that malfunction of the crankcase oil scavenge is causing the excessive exhaust smoke. Although oil should spurt from the scavenge return pipe into the tank, it is normal that air and bubbles also will issue from the pipe at intervals. This is because the scavenge side of the oil pump is of much higher capacity than the pressure side. A large quantity of air is therefore sucked from the crankcase. The oil tank filler cap is provided with an air vent hole. If this hole becomes blocked, the oil tank will become pressurized, reducing the scavenge system efficiency, which in turn will cause the crankcase to partially fill with oil. The piston oil control ring will not be able to handle the large quantity of oil on the cylinder wall, and will therefore allow oil to pass into the combustion chamber.

(Continued on page 24)

Continued from page 20

However, if this is not the problem, I would first re-check to determine that all the oil scavenge lines between the pump and tank are free of partial blockage. Then remove the oil pump. Check that the hole in the pump actuating link has not become worn or elongated, as this would cut down the pump stroke and, therefore, pump efficiency. Check that the pump check valve seats are in good condition, that the ball valves are not pitted, or that the check valve springs have not lost their tension. When refitting the ball valves, give them a sharp tap to insure a good seat. After the pump has been checked out and rebuilt, check that the crankcase scavenge pipe is not cracked, or that there is an air leak where it enters the crankcase. If, because of a defect, this pipe is sucking air at a point above the oil pickup (situated in the base of the sump), the pump will not suck oil until the oil level in the crankcase has risen to the leakage point. Also, check that the oil filter in the base of the crankcase is not blocked.

I am sure your problem is caused by inadequate crankcase scavenging. However, another likely place for oil to get into the combustion chamber is down the valve guides. This can occur as the result of worn valve guides or excessive oil delivery to the rocker box. The rocker shafts and related components on the Cub are lubricated by oil scavenge pressure. This pressure is partially regulated by restricting the scavenge return pipe into the oil tank. If you look at the end of the pipe you will notice that it has been squeezed to restrict the outlet. Further restriction would cause more oil to be forced to the rockers. Relieving the outlet would reduce the rocker feed. If the outlet were over-restricted, this would cut down the scavenge efficiency and allow the crankcase to partially fill with oil.

WHAT'S WHITWORTH

I recently ordered a Cotton Cossack Scrambler equipped with a Villiers Starmaker Mk II engine. I understand the British use the Whitworth system. My understanding of this system is, however, limited. I think that the wrench size for a bolt is named by the diameter of the bolt and not its head. Are the heads of these bolts, however, the same as those of American bolts? What it boils down to is: Can I use standard American wrenches on this machine of mine, or won’t the wrenches fit?

Philip J. Weeks Hanover, N.H.

The manufacturers of British motorcycles use three basic thread forms. There is BSW (British Standard Whitworth), which is a coarse thread, BSF (British Standard Fine), which is a fine thread, and a special cycle thread is used, which is also fine and always has 26 threads per inch. In the majority of cases the cycle thread is used for engine mounting bolts and wheel axle threads.

As stated by you, the wrench size is directly related to the thread size in all cases. A BSW bolt has a larger hexagon head than a BSF of the same diameter. However, there is some relationship, because a set of BSW wrenches can be used on the BSF and cycle thread hexagons. As an example, a one-quarter BSW wrench will fit a five-sixteenths BSF hexagon. No, you cannot use standard American wrenches on the British nuts and bolts. It will be necessary to buy a set of BSW wrenches ranging from one-eighth to seven-eighths to meet the majority of your requirements.