SPRING FRAME PROGRESS

Its History and Engineering

RICHARD C. RENSTROM

THE SPRING FRAME on the modern motorcycle is taken for granted by the majority of today’s riders. Yet of all the current engineering specifications this feature has probably taken the longest period of time to become accepted practice. It was not until 12 years ago that the now common swinging-arm suspension became universally accepted, and only twenty years ago, very few models were available with any type of rear suspension.

The desirability of rear wheel suspension was recognized more than 50 years ago when a number of makers experimented with many different types of spring frames. The poor handling that all these early springers exhibited caused the suspension principle to acquire a bad reputation and the world settled down to enduring the rough ride of the rigid frame.

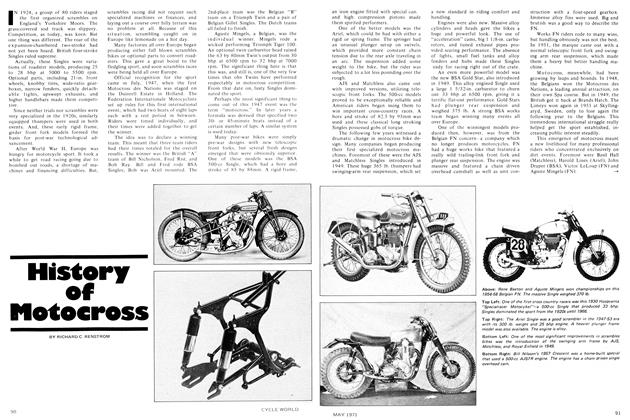

It was not until the mid-thirties that any significant progress was made on the problem, but, when the famed Stanley Woods romped home to victory in the 1935 Senior TT on his “springer” Guzzi, the world’s manufacturers began to give some serious thought to the spring frame. By far the most successful of the designs that subsequently made their debut, at least as far as being adopted for roadster use, was the plunger suspension as proven on the 1936-49 Norton works racers. Norton’s goal was to provide a more comfortable ride, keep the rear wheel in contact with the road at all times, and improve handling by damping out the bounce of the machine when the rear wheel hit a sharp object.

The main attribute of this plunger suspension was its ease of production and the softer ride that it provided, compared to the rigid frame. These reasons alone were sufficient to cause the plunger frame to be widely used on roadsters after World War II.

The system had its faults, though, ^and foremost was the deflection of the wheel from the center vertical plane. With any system employing two sliding members joined by an axle, it is possible for one side to move upward on compression more than the other side. This, of course, means that the wheel will tilt from the vertical, and that can do the navigation of the bike no good. At high speeds a weaving motion may be noticeable on washboard surfaced pavement, and this can be disconcerting, as well as dangerous to the rider.

Another problem with the plunger suspension was its lack of rebound damping. The units contained only a compression spring, and the energy stored in the spring upon compression was quickly expended in a rebound action. This made for a sharp action over a bump, although the ride was still much smoother than the rigid frame.

Another weakness of the plunger suspension was the variation in driving chain tension through the suspension cycle. For the chain to remain in a constantly correct tension the rear axle movement must be in an arc. The plunger suspension moved only straight up and down, however, so the chain had to be adjusted a little loose at the center point of the suspension cycle in order to be in correct adjustment at the two extremes of compression and rebound. This loose adjustment at the mid-point was often the cause of the chain jumping off the sprocket, particularly when heeled over in fast cornering on a rough road.

The problem of the wheel canting over from vertical was a serious drawback in road racing, as the handling left something to be desired. In an effort to improve this lack of lateral rigidity in the wheel, several of the most prominent racing marques of the pre-war days developed the use of a pivoting fork to the axle which was then attached to the plunger boxes. Notable among these famous makes were the DKW, Benelli and AJS. To implement this method a fork was used that is nearly identical to the fork on a contemporary swingingarm suspension. The wheel was therefore prevented from tilting from the vertical plane, but the length of travel was rather limited due to the pivoting fork traveling in an arc at its outer end while the spring boxes could move only up and down.

Across the European continent in Italy, another great name in racing was attempting to devise the ultimate in a spring frame, and the Moto Guzzi did make some notable contributions to the science. During the 1930s and for a few years after the war, the Guzzi used a sort of pivoted-fork suspension that was designed to provide a constant chain tension, as well as give some damping action to the rebound of the springs.

The method employed a triangulated fork which pivoted at its upper joint. The bottom of the fork attached to a long spring box that was mounted beneath the engine. This pivoted fork provided a constant chain tension, as it traveled in an arc from its pivot point. For some damping qualities, a unique scissor-action affair was attached to the rear of the fork and to a top frame extension, the center of which had a small friction-pad assembly that could be hand-adjusted to alter the amount of friction. The system worked quite well, as the wheel was reasonably rigid in regards to lateral rigidity, and the suspension characteristics were better than the straight plunger springs.

This desire to maintain constant chain tension was very important on a road racing bike; so many marques tried some sort of method based upon the pivoted-fork principle. One of the pioneers was the Vincent-HRD of the early 1930s. The Vincent idea used a triangulated rear fork, only this one was pivoted at the bottom and the angle of the triangle was much greater than the Guzzi’s. The spring units contained only coil springs, and these were mounted at the top of the frame beneath the seat. The upper end of the fork pushed against the suspension units, and the rear wheel had good lateral rigidity. The big drawback was that the rear seat was mounted on the frame and the frame moved up and down in the suspension cycle.

All this activity in rear suspensions was bound to culminate into a really superior design, for, sooner or later, some engineer would combine all the good features while dispensing with the bad. The credit for this final development goes to Velocette, when their 1936 works racers appeared with a swinging-arm frame. These Velo racers proceeded to establish a tremendous reputation for their superb handling and road holding qualities during the late 1930s.

It is rather surprising, considering the fact that the Velocette’s swinging-arm design is identical to those in common use today, that it took so long for the world to accept its superiority. After its introducion on the 1939 producion MK VIII KTT racer, no one followed the Velocette method for roadster use until 1949, when Royal Enfield, AJS and Matchless adopted it. Even such production leaders as BSA and Triumph did not adopt the swinging-arm method until 1954, and it even took some of the continental sales leaders a few more years to make the switch. Probably the only reason that can be given is the cost factor, since a swinging-arm suspension does require some well designed parts, as well as accurate machine work.

In the Velocette system the frame had two straight extensions back from the top of the center down tube, and then the tubes bent forward at about a 45° angle back to the bottom of the center frame tube. The swinging-arm was a rugged fork that was mounted in massive bronze bushings on a wide lug on the down tube as close as was possible to the center line of the driving sprocket. For suspension units, the factory used Dowty air-oil shocks which provided both compression and rebound damping. The shocks were pumped up to about 35 pounds pressure, and this provided the resistance for compression. The rebound damping was provided by oil passing through large orifices on the compression stroke and then forcing the oil to flow back more slowly through smaller holes.

This system provided the desired features of a constant chain tension through the arc of suspension travel, a very rigid rear wheel in regards to vertical stability, and the damping of the shock unit on the rebound from compression. About the only change that has been made in the original Velocette scheme is the use of standard spring-oil shock units instead of the air-oil assemblies. The reason that Velocette used the air-oil units was due to the non-availability of spring-oil shocks in those early days, while Dowty units were already available because they were commonly used on airplanes.

Before leaving this evolution of the suspension system it would be best to make note of one other method that was rather unique. This was the “spring hub” as used on Triumphs from 1948 through 1953. The idea was to get a compact, clean looking suspension by containing the system within a large nine-inch diameter rear hub. Internal springs were used, and the axle traveled in an arc to maintain a constant chain tension.

The unit did have the advantage of being attractive, but the wheel was rather free to tilt or cant from the vertical plane with some rather bad effects on handling. The Triumphs of that era were rather infamous, for instance, of being prone to speed wobbles. Another drawback was the limited amount of suspension travel, which was considerably less than the swinging-arm method. So, in 1954, the spring-hub was wisely dropped in favor of the newer and better method, and Triumph, like all the others, is a better bike because of it.

There are some disadvantages inherent in the swinging-arm principle, and probably the most obvious is that the axle is a long way from the bearings in the fork that hold the assembly vertically rigid. The wheel, therefore, exerts a great deal of leverage, and it is necessary to have the two bearings that mount the fork as far apart as possible. The fork, itself, must be strong enough to resist twist, and any skimping in these places can produce a bike that lacks lateral rigidity.

This lack of rear wheel vertical rigidity is apparent in some contemporary roadsters, too, and a good wiggle of the handlebars at a road speed of 50 or 60 mph can induce some very undesirable results. On one oriental import that I recently rode, this handlebar shake set up a very noticeable wobble that took a few yards to work itself out!

The lack of strength in the rear fork can also have some bad effects on the driving chain and sprockets. If the fork is so weak that it flexes when the power is applied, there will be a rapid sprocket wear, as well as a weaving tendency at high speeds. If this condition is bad enough, it is even possible to have the chain jumping the sprocket, although a fork would have to be quite weak for this to occur.

As far as the suspension units themselves are concerned, there appears to be little criticism that can be leveled at the spring-oil method. The oil does have a tendency to heat up in hard use, and this lowers the viscosity so that the oil flows much more freely. The return damping will therefore be less as the oil heats, because the fluid can return so much quicker through the tiny orifices. This oil heating problem is the reason for removing the covers of the shock units, as the heat is better dissipated this way.

Another avenue for improvement might be to obtain more progressive compression of the coil spring. With a standard coil spring there is a constant rate of compression — the last inch of compression has about the same rate as the first inch. Research conducted on works grand prix bikes back in the mid-1950s pointed up an improvement here, as they had coil springs which were wound tighter toward the bottom, thus providing a stiffer spring as the suspension compressed.

This increasing rate of compression was one great advantage of the Dowty air-oil shock as used on the KTT Velocettes. The rate of air being compressed increases, instead of remaining constant, so that it takes twice as much pressure to compress it the second inch as it took for the first. It is also impossible to compress a volume of air into no space at all, so the shock units would never be able to bottom. The cost factor of the air-oil shock is rather high, however, and the units do require more careful maintenance than the common spring-oil units.

So this is the story of the spring frame — a chapter in the evolution of the motorcycle that has had great benefit for today’s rider. Down through the years many methods have been tried, but by the late 1950s almost everyone had adopted the swingingarm principle. From the grand prix courses to your roadster — it is a story of comfort and improved road holding. ■