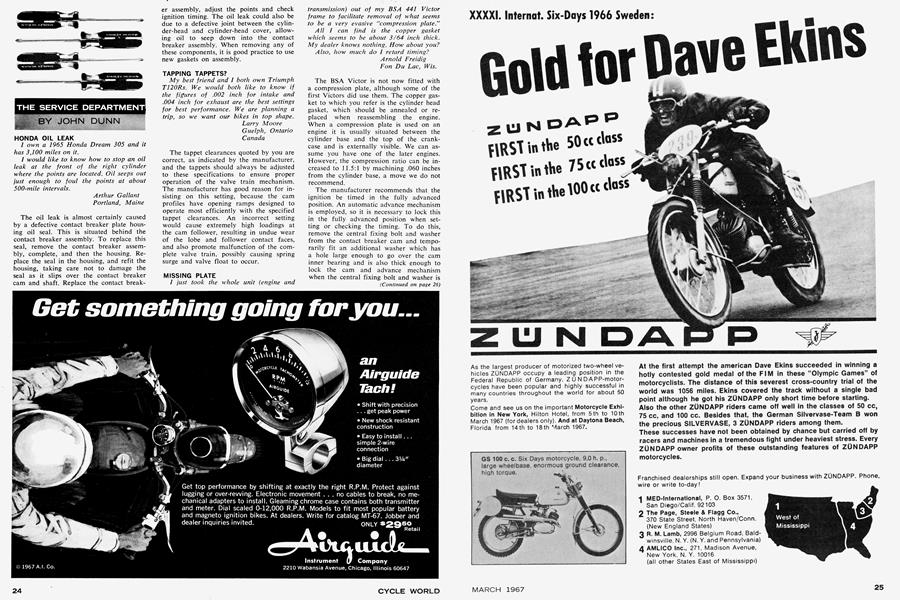

THE SERVICE DEPARTMENT

JOHN DUNN

HONDA OIL LEAK

I own a 1965 Honda Dream 305 and it has 3,100 miles on it.

I would like to know how to stop an oil leak at the front of the right cylinder where the points are located. Oil seeps out just enough to foul the points at about 500-mile intervals.

Arthur Gallant Portland, Maine

The oil leak is almost certainly caused by a defective contact breaker plate housing oil seal. This is situated behind the contact breaker assembly. To replace this seal, remove the contact breaker assembly, complete, and then the housing. Replace the seal in the housing, and refit the housing, taking care not to damage the seal as it slips over the contact breaker cam and shaft. Replace the contact breaker assembly, adjust the points and check ignition timing. The oil leak could also be due to a defective joint between the cylinder-head and cylinder-head cover, allowing oil to seep down into the contact breaker assembly. When removing any of these components, it is good practice to use new gaskets on assembly.

TAPPING TAPPETS?

My best friend and 1 both own Triumph T120Rs. We would both like to know if the figures of .002 inch for intake and .004 inch for exhaust are the best settings for best performance. We are planning a trip, so we want our bikes in top shape.

Larry Moore Guelph, Ontario Canada

The tappet clearances quoted by you are correct, as indicated by the manufacturer, and the tappets should always be adjusted to these specifications to ensure proper operation of the valve train mechanism. The manufacturer has good reason for insisting on this setting, because the cam profiles have opening ramps designed to operate most efficiently with the specified tappet clearances. An incorrect setting would cause extremely high loadings at the cam follower, resulting in undue wear of the lobe and follower contact faces, and also promote malfunction of the complete valve train, possibly causing spring surge and valve float to occur.

MISSING PLATE

1 just took the whole unit (engine and transmission) out of my BSA 441 Victor frame to facilitate removal of what seems to be a very evasive “compression plate.”

All I can find is the copper gasket which seems to be about 3/64 inch thick. My dealer knows nothing. How about you?

Also, how much do 1 retard timing?

Arnold Freidig Fon Du Lac, Wis.

The BSA Victor is not now fitted with a compression plate, although some of the first Victors did use them. The copper gasket to which you refer is the cylinder head gasket, which should be annealed or replaced when reassembling the engine. When a compression plate is used on an engine it is usually situated between the cylinder base and the top of the crankcase and is externally visible. We can assume you have one of the later engines. However, the compression ratio can be increased to 11.5:1 by machining .060 inches from the cylinder base, a move we do not recommend.

The manufacturer recommends that the ignition be timed in the fully advanced position. An automatic advance mechanism is employed, so it is necessary to lock this in the fully advanced position when setting or checking the timing. To do this, remove the central fixing bolt and washer from the contact breaker cam and temporarily fit an additional washer which has a hole large enough to go over the cam inner bearing and is also thick enough to lock the cam and advance mechanism when the central fixing bolt and washer is replaced and tightened. To obtain the full advance position, rotate the cam fully counter-clockwise before tightening. Before checking the timing, ensure that the contact breaker points are in proper adjustment. The points should just break when the crankshaft is 28 degrees or that the piston is 0.265 inch before tdc on the compression stroke. If adjustment is required, loosen the contact breaker pillar bolts and rotate the plate either backward or forward until the correct timing is obtained; then re-tighten the pillar bolts. After the timing has been finally set and double checked, remove the thick cam locking washer; otherwise the auto advance mechanism will not operate. BSA recommends the same ignition timing for the 11.4:1 engines as those having a compression ratio of 9.5:1.

(Continued on page 26)

MORE INCHES

Having found New York motorcycle dealers in general a rather nasty bunch, 1 turn to you for some advice on pepping up my 66 Honda 160. What I’m looking for is a little more spunk in acceleration while retaining a cruising speed of about 60 mph. I have considered the various “bolt on” bore kits available, but don’t wish to do anything rash until I have all the facts. Would a high performance cam help fulfill my needs? 1 have also considered changing the rear sprocket. If this is a good idea what size would you recommend and where can one be obtained?

Any and all tips on increasing the bike’s acceleration performance will be greatly appreciated. Keep up the good work. 1 like your style.

Michael Gallagher

Brooklyn, N. Y.

The easiest way to increase mid-speed torque and acceleration without adversely affecting reliability and long-term durability would be to employ one of the bigbore kits. An increase in displacement when employed with the existing combustion space will also result in an increase in compression ratio.

A high-performance camshaft kit would be of some advantage, particularly where the big-bore engine is concerned, by providing improved breathing capabilities at the top end of the speed range.

Your requirements will possibly be satisfied without changing final drive sprockets. A noticeable improvement in acceleration would be obtained by a slightly lower ratio. This can be obtained by increasing the rear wheel sprocket by two extra teeth or alternatively by reducing the gearbox final "drive sprocket by one tooth.

DUAL-TWIN TIPS

1 am a high school Industrial Arts teacher and an avid motorcycle fan. Six months ago, I purchased a 1966 Bridgestone 175cc Dual-Twin. 1 have since accumulated a vast storehouse of unanswered questions about this machine.

My best speeds to date (1,200 miles) have been: 75 mph in third gear, 78 mph in fourth, and 72 mph in fifth. I weigh 200 pounds. Would a larger rear sprocket improve top end speed? How much larger? The bike has no “snap acceleration” below 10 mph. Can this be improved? How? The bike smokes excessively when accelerated hard. Is this normal? I am burning Gulf two-cycle oil.

(Continued on page 28)

When one cylinder is shorted out, I get a weak exhaust pulse from that cylinder. Also, with both sparkplugs removed, 1 get an almost nil compression reading. Is this normal for this machine or does it indicate a blown center seal?

What standard is used to verify excessive engine temperature if a temp gauge is not available?

I would like to convert this machine into a “street scrambler.” What is the maximum width tire that may be used on stock rims? Is a rake plate available for this machine? Heavy duty fork springs? Would heavier fork oil improve ride in the rough? How heavy?

J. V. McIntosh

Troy, N. C.

Your machine is definitely over-geared for maximum performance. An increase of two teeth on the rear wheel sprocket should improve maximum speed and overall performance. Considering your weight, it may be necessary to go to three additional teeth on the rear wheel sprocket. However, the final choice will have to be decided by trial and error. Snap acceleration will also be improved due to lower overall gear ratio.

Although the 175 Dual-Twin is equipped with a pump-metered lubrication system, the manufacturer does recommend that two-cycle oil is also mixed with the fuel at ratio of 20:1 for the first 250 miles. After this initial period, do not add oil to the fuel. I mention this because it may be the reason for the excessive smoke when accelerating hard. The smoking may also be due to an incorrectly adjusted oil metering system. To adjust this, open the throttle fully at the handlebar and then check the position of the oil pump metering control arm. If this is correctly adjusted there will be 1/8 inch clearance between the control arm and the control arm stop pin. Adjust, if necessary, to obtain the correct clearance by means of the cable adjusting screw.

When you carried out the compression check did you have the throttle fully open? If the throttle had been closed, the gauge readings would be very low. With the performance that you are obtaining, it is very doubtful that a center oil seal is defective.

Engine distress due to excessively high temperature is usually easily detected on a two-cycle by an audible pinging sound when under load. If the machine is continuously driven under these adverse conditions, serious damage and possible seizure is likely to occur.

It should be possible to go to a 3.50 section tire without encountering any difficulties. However, the large section tire will result in higher overall gear ratios, so make additional allowance for this when selecting the alternative rear wheel sprocket. For street use, I would not bother with altering the rake and trail. If stronger fork springs are not available, they can be made stiffer by inserting spacers (collars) around the inner tube (stanchion) between the top of the spring and the underside of the bottom fork yoke. A spacer an inch thick would be a good starting point. To increase the damping effect of the forks, try using an SAE 20 oil, filling each leg with 220cc (7.5 fl. oz.). The rear suspension units are not easily worked on, so it would be advisable to find an alternative unit that will meet your requirement.

HIGH VOLTAGE CIRCUIT

This is a diagram of the secondary circuit of a Honda 305 Dream.

Please note that the spark plugs are in a series and are connected to either end of the coil secondary. This is how it is shown in the book and it checks out like this with an ohmeter.

My question is: How can one plug fire when the other is out? 1 know that it does because it will run on one plug (cylinder,, if you will) while the other lead is disconnected.

Joseph R. Restle Cincinnati, Ohio

It is apparent from the contents of your letter that you have some basic knowledge of the behavior of electricity. However, your theories have been based on the habits of low voltage current which would require a circuit in keeping with your train of thought to function. This does not necessarily apply to high voltage current, which will discharge to a lower potential without the assistance of a mechanical circuit (connected circuit). The Honda twin lead coil will still function with one lead disconnected due to this phenomenon; however, efficiency will be impaired and peak voltage will be lower than would be the case if both leads are connected.

“SIX OF ONE AND..."

I realize it is contrary to your policy to endorse any particular make of motorcycle; perhaps you can help me out if I refrain from mentioning any names.

I can’t seem to get a straight answer from two dealers concerning their products. One sells a 250cc two-stroke with a six-speed, the other, a rotary valve job of the same displacement with a five-speed. Both are Japanese with very similar performance, finish and price, and they both have features attractive to me.

The question is dependability and long life. Dealer “A” says the piston-port job will be easy to start day in and out and will outlast the other make, due to its simplicity. Dealer “B” claims the same. Is one design better, or is it a case of “six of one and a half dozen of the other?”

If you aren’t a mechanical engineer (which 1 am not) it’s pretty tough trying to separate the sales “yak” from the facts, and trial by error is expensive.

(Continued on page 30)

Incidentally, 1 think CYCLE WORLD is excellent. I’ve been reading it for some time, even though 1 have not owned a motorcycle for eight years.

M. Greener Lakeland, Fla.

Both the machines to which you refer are first class, it being a very difficult task to make a choice between them. As you say, technically it is “six of one and half a dozen of the other.” Theoretically, the five-speed rotary valve model would appear to offer a little more, but in practice, where street applications are concerned, there does not seem to be anything in it. With reference to your question related to dependability and long life, there is no technical reason why one should outlast the other, providing proper care and attention is given to routine maintenance. The final choice will have to be one of personal preference, which should be mainly influenced by your impressions after riding a good example of each model.

AN UPHILL VICTOR

/ am the owner of a 1966 BSA 441 Victor, which I wish to use for hillclimbing. In the power and torque department the performance is superb, but 1 find myself limited by not being able to keep the front end down. Standing up and leaning forward help, but I would certainly appreciate any hints or suggestions that you could offer regarding modifications which would help solve my problem.

Harry V. Langeluttig Jr., M.D.

Ft. Leonard Wood, Mo.

The easiest way to overcome your problem without incurring any adverse effects is to lengthen the rear swinging fork. The B44 has a relatively short wheelbase at 53 inches; an increase of two inches, extending it to 55 inches will make a big difference to the weight distribution. The machine will then be more stable and controllable over fast jumps and when ascending steep inclines with the power hard on. Before attempting to lengthen the swinging fork it would be advisable to construct a simple jig to hold the fork in position after it has been cut and during welding to ensure correct alignment. If the machine is to be used only for hillclimbing, a smaller diameter front wheel is also worth considering.

If any other reader has converted a Victor for hillclimbing purposes, I would be pleased to hear from him and pass on the information to Dr. Langeluttig.

CHAIN SLACK

When adjusting the drive chain on a motorcycle, is the required 1/2-inch to 3/4-inch slack or movement measured with a straight edge lying parallel with the chain across the two sprockets?

K. G. Wood

APO San Francisco, Calif.

The figures referred to by the manufacturer are for total up and down movement. In other words, take hold of the Ochain midway between the gearbox output sprocket and the rear wheel sprocket, pull it up as far as it will go, then push it down as far as it will go. The total movement should be measured; in most cases it will be between half and three quarters of an inch. To be certain, use the dimension advised by the manufacturer. The manufacturer will also indicate which attitude the machine should be in when checking (whether the machine should be on its center stand, upright on its two wheels, or with the rear suspension partially compressed).

A chain stretches with use, quite often unevenly. This will result in tight and loose sections when the rear wheel is rotated. Always adjust the chain when it. is at its tightest point. A chain should be properly lubricated with no tight links before adjustment. Tight links will also have the adverse effect of severe sprocket wear and also cause premature failure of transmission bearings in the gearbox and rear sprocket carrier, the latter being used with most quickly detachable rear wheels.

PATIENCE REWARDED

1 thought you might be interested in my break-in experiences with a 1965 Super Hawk. The first 1,200 miles were run no faster than 55 mph with occasional bursts to 65 or 70 mph. Prior to the first 2,800 miles, the machine would not pull over

8.500 rpm at 80 to 85 mph. Why? The machine was “babied” through the first

2.500 miles and the engine was still a little tight. 1 now have over 4,200 miles registered; 9,000 rpm and speeds in excess, or very near 100 mph, can be attained quite easily. During the first 1,200 miles, oil was changed every 500 miles. 1 believe normal routine maintenance, faithfully carried out, played a major role in a recent two and one-half day trouble-free jaunt from Grand Forks, North Dakota, to New Orleans, Louisiana.

Thanks for the fine magazine.

Michael Clark New Orleans, La.

Although the break-in procedure used by you was rather a long one, it was obviously successful, as demonstrated by the good performance now being experienced. Regular oil changes are most important, particularly in engines that have a relatively small oil capacity, like the 250cc and 305cc Hondas.

You answered your own question which inquired why the machine wouldn’t attain maximum performance at 2,800 miles. Due to the prolonged break-in period it was still a little tight. ■