[TECHNICALITIES]

GORDON JENNINGS

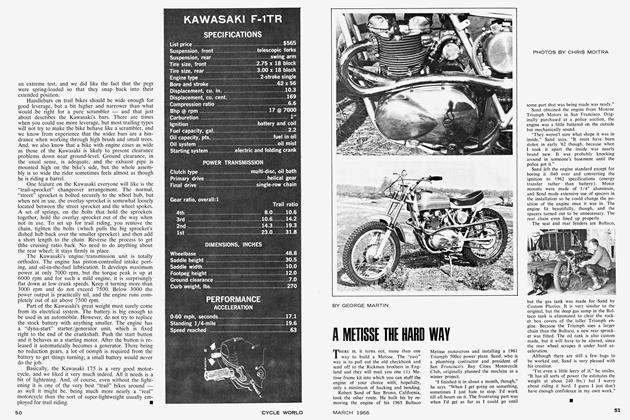

NEARLY EVERYONE HAS heard of the Society of Automotive Engineers. What you may not have heard is that the SAE is very much more than a social club. It serves a valuable function in the interchange of ideas and information via the publication of engineering papers. These may have as their subject a new design, product or process, or they may be a report on research.

In that last category is a paper written by one Yoshio Nakamura, of the Honda Research and Development Company, Ltd. The paper’s title, “Small High-Speed, High-Performance Gasoline Engine,” only hints at its contents, which cover Honda’s research into gas-flow, valve-gear behavior, combustion, and mechanical efficiency at crank speeds above 14,000 rpm. Unfortunately, the coverage does not offer much depth, but there are some interesting clues about those famous and somewhat mysterious Honda racing engines.

One especially important point made in the paper, and made right at the onset, is that the Honda racing engines have not been developed from a base of any radical fundamental theories. Rather, design work has consisted of pressing forward the current technology. “Forward,” in the case of the reciprocating internal-combustion engine, is in the direction of higher crankshaft speeds. That, if we are restricted against the use of supercharging or oxygen-bearing fuels (such as nitromethanol), is the only source of substantial increases in power output. Of course, the increased power will not fully materialize if attention is not given to volumetric efficiency, and to running friction. Honda’s research program has been directed at finding solutions to these implied problems.

The primary limit of engine speed is set by inertia loads on the reciprocating parts in the crank and valve-gear assemblies. Thus, the first step must be to reduce the mass of those parts — and the most effective method of doing that is to divide the engine’s displacement into a greater number of cylinders. Obviously, this brings an undesirable increase in complexity, but it is easier and less expensive, in the long run, than trying to accomplish the same thing with unconventional design and exotic alloys.

In the same line, the easiest means of countering high-rev valve-gear problems is to use a greater number of valves, with each individual valve being smaller and lighter. In this connection, it is interesting to see, in Nakamura’s paper, that Honda obtained a 30-percent reduction in effective valve-gear mass by going from a 2-valve to a 4-valve cylinder head on a single-cylinder test engine. This moved the critical engine speed (where the valve gear begins to do things the camshaft doesn’t like) up from 10,000 rpm to

16.000 rpm.

Even better results were obtained by dividing the single cylinder’s displacement by two. The resulting twin-cylinder engine, with conventional two-valve heads, gave a 42-percent reduction in valve-gear mass (as compared to the original 2-valve single) and moved the critical speed up to

19.000 rpm. Then, in the final logical step, they again changed to a 4-valve cylinder head configuration (valve mass down 51% from original) (8 valves in all) and pushed the critical speed to

21.000 rpm. That is, you must understand, the lower limit of valve float. The point of serious valve crash, where the valves cease to follow the cams and bounce around all by themselves, is up around 24,000 rpm.

No figures for piston acceleration are given, nor are the stroke/rod length figures from which piston acceleration can be calculated. However, it is noted that mean piston speeds are held below 4000 ft/min, and that piston rings 1.0 to 1.5 mm thick perform up to that limit “without undesirable effects.” Obviously, whatever techniques needed to keep those tiny pistons, rods and crank together at speeds beyond 20,000 rpm were found, or there would have been no data available in that range. Actually, with the individual cylinders small enough, the problems are not very great in any case. Cheap, massproduced model airplane engines, with oil-mist lubrication and shockingly bad bearings, run reliably at 18,000 rpm just because the moving parts are so small and light. Honda’s racing engines do not, of course, have model airplane size cylinders, nor are they cheap or mass-produced, but there is a valid comparison here in terms of what can be done with reductions in unit cylinder volume.

All those revs are to no avail if the air cannot be kept moving through the engine. My personal opinion has long been that the Honda engines do not breathe particularly well at their ultra-high peaking speeds, but according to Nakamura’s paper, I am wrong. Volumetric efficiency (nominal cylinder capacity, compared to the volume of air actually drawn into the cylinder) for at least one engine was above 100% at 12,000 rpm, which implies that ram-tuning techniques are effective enough, even at very high crank speeds, to pack more air into a cylinder than it would contain if the engine was stopped and the intake valve held open.

A chart, with volumetric efficiency plotted for two unspecified test engines, shows near-100% filling all the way up to 18,000 rpm — where the chart stops. There is a hint of a downward trend in the plot-points, but it is clear that the limit has not been reached even at 18,000 rpm. Certainly, there is not enough loss to cancel the power gain inherent in the higher running speeds.

Most surprising is the claim of a progressive reduction in mechanical losses with greater numbers of cylinders. According to an engine speed/mechanical efficiency chart, comparing single and twin-cylinder test engines of the same capacity, the twins give away less power to friction than the single at all crank speeds. It is said, in the paper, that this reduction in friction was made possible because the lower inertia loads permitted smaller bearings. Quite a point was made of the fact that bearing diameters and widths must be held to a bare minimum, and also that for high-speed operation, only needle and ball-type bearings should be used. Plain bushings run at much ^greater friction loss at high speeds, probably due to viscous shear in the lubricating-oil film, and to that loss must be added the power required to drive a highpressure, high-volume output oil pump. It may also be assumed, though the paper says nothing about it, that steps have been taken to avoid “windage” losses between crank and crankcase. The low-drag characteristics of the very narrow piston rings are said to be quite important to the overall friction reduction.

(Continued on page 24)

continued

One point that has been raised in connection with ultra-high engine speeds is the possibility of some limit in the combustion process. Between the moment of ignition, and the piston reaching top center, the combustion process should be substantially complete, and the time available for the completion of this process is very short at, say, 16,000 rpm. Fortunately, the worriers do not have to worry much just yet. In a 62.3cc, single-cylinder test engine, it was found that the primary flame-front propagation increased in almost direct proportion with increases in engine speed. Probably, this can be traced to a progressive rise in mixture turbulence — which “stirs” the fires and makes it advance more rapidly.

An interesting side-light to this business of high engine-speed combustion is that the octane requirement drops sharply above 11,000 rpm. A test engine (62.3cc, single cyl. ), running at 7000 rpm gave normal combustion on fuel having down to a 70 octane number rating. This requirement remains constant, with detonation occurring at about 68 octane, up to 11,000 rpm. Then, there is a rapid drop in octane requirement, with the onset of detonation moved down to about 58 octane at 13,000 rpm. This trend continues, down to about 53 octane at 15,000 rpm and 52 octane at 17,000 rpm. What all this means is, of course, that very high compression ratios can be used at high crank speeds without fear of detonation.

This low octane requirement may, however, prove to be nothing but a theoretical benefit. The physical requirements of high compression ratios include a piston crown that fills all possible space in the combustion chamber. To do that, its shape becomes very irregular, with little lumps and ridges and deep pockets for valve clearance. In actual tests, Honda found that not only was breathing adversely affected by all these piston-crown convolutions, but there was a bad effect on combustion as well. In the end, Honda’s development engineers settled for a slightly lower compression ratio, finding compensation in the improved breathing and combustion.

(Continued on page 26)

continued

A clue to the direction of further Honda racing design is provided by a chart plotting engine speeds over the past decade. In 1955, the plot starts at 7500 rpm. By 1957, it is up to about 11,000 rpm, and the curve climbs steadily, reaching 22,000 rpm in 1964. A projection goes to 25,000 rpm in 1965, and should take Honda to 27,000 rpm in 1966.

Where will all this lead? Honda engineers do not know. Nakamura’s paper concludes that “dynamic effects of the intake and exhaust systems can be sufficiently utilized to improve air breathing capacity in high speed ranges of not less than (my italics) 10,000 rpm.” He also states that “no limit has been observed in the successive occurrence of combustion.” Finally, he observes that “In the small, high-speed engine, mechanical loss tends to cause power loss at a high rate to engine output” but goes on to explain that careful design work can reduce such losses “to a large extent.”

As I interpret all this, and the content of the engineering paper itself, Nakamura is saying that no limits have been found in the areas just mentioned. However, in the final paragraph of Nakamura’s concluding remarks, he drops the other shoe. Quote: “Fundamental problems remain

to be solved with regard to valve floating. They include how to (further) reduce the mass of moving parts and how to properly select satisfactory material for valve springs.” In other words, sports fans, they are reaching the limit in reducing the size of individual valves, and a limit to the performance of valve springs. Flexing causes valve spring fatigue and heating if rapid enough, and the rate of flexing at a crank speed of 25,000 rpm is 12,500 spring compressions per minute.

Valve spring problems, under such conditions, are entirely understandable. In the end, it will probably be the springs that establish the limit, for with such a tremendous rate of flexing, valve spring life could be reduced to a matter of minutes before the coils began to “settle” and lose their tension. That would progressively lower the speed at which valve-float occurs, and power would fade away during the course of even a relatively short race. When and if this problem is truly resolved, it would be extremely interesting to know the details of research leading up to the resolution. Or, perhaps Honda’s engineers will elect to side-step the problem entirely, with some form of “desmodromic” (positive opening and closing) valve gear. ■

![[technicalities]](https://cycleworld.blob.core.windows.net/cycleworld19660301thumbnails/Spreads/0x600/10.jpg)