THE SERVICE DEPARTMENT

GARY BRAY

DEAD SPOT

I own a 1964 Matchless GS0 CSR. I want to run an open exhaust system. Using a 440 main jet, with plug, points and rocker clearances correctly set, I get tremendous acceleration from standstill, but when cracking the throttle wide open from a 40 mph idle, the machine "dogs" and "coughs" giving no go whatsoever. I've also tried a 360 jet with the same results. My needle was in the center notch and my air cleaner is connected. My manual indicates using the 440 jet but I can't seem to get any positive results. What do you suggest?

Dave Sobeck Ann Arbor, Michigan

A lack of engine response when the throttle is opened quickly is an indication that the carburetor slide cutaway is too large. Raising the slide needle will have some slight effect on the prob lem, but will cause the engine to run rough at a steady or cruising throttle iosition.

Replacement of your present carburetor slide with one that has a smaller cutaway should solve the trouble. Each slide has a number stamped on its top, designating the amount of cutaway. If your machine is fitted with a #3½ slide, it should be replaced with a #3 slide. With a little experimentation, sure throttle re sponse can be achieved.

COMPRESSION'S GONE AGAIN

In July 1963, 1 bought a used 1963 Ducati 250cc scrambler. I hadn't ridden it but a few months when I found that I had `lost my compression. I tore it down and found that it had a busted ring. The cylinder was not scored so I didn't bother reboring it. I bought a new piston, complete with rings and wrist pin, put it back together. Rode it for a few months and 1 lost compression again. I tore it apart again and found that the top ring on my piston was busted again. The piston was not hurt and the cylinder wall was not scored so I put new rings on the piston and put it back together. 1 rode it a few months and the same thing happened again. This time I rebored my cylinder to .024 over and shaved .020 off my piston, thinking it may be hitting the head. Now, a few months later, no compression.

I was told to change from the standard Ducali air cleaner to some other type. Do you recommend any special air cleaner? Or does this make any difference?

Calvin Bowling Okanogan, Washington

Since your machine is a scrambler model I shall assume you do some leaping around off the beaten path, and maybe even par take of a little competition now and then. Under these conditions the engine will be well used. This will have some bearing on the life of your machine's upper end.

First off, a total loss of compression cannot be attributed to one broken ring, or even two for that matter. A gradual loss of compression over the period of a few months will be due to nor mal or abnormal wear of piston rings and cylinder bore. Wear rate of these parts depends on how much and how hard the ma chine is used and the conditions under which it is ridden. If raced frequently, the wear rate would be high, with the top end needing attention every few races to keep it sharp.

On the other hand, such trouble with normal pleasure riding indicates abnormal engine wear. In both cases that villain could be a deficient air cleaner. The standard Ducati air cleaner should be sufficient, even for racing, providing dusty or sandy conditions are not encountered. Used in a dusty or sandy environment, the ma chine should be equipped with a Fram-type air filter. This type of air cleaner installation will in all likelihood have to be hand made. The Fram #CA7O i'1~n~r 1~ment wniild h~ me~st desirable.

(Continued on page 22)

To cure the piston ring breakage you are having, two things should be tried. First, the top piston ring should be posi tioned with the ring gap in line with the wrist pin. This positions the ring gap away from the thrust sides of the piston. Sec ondly, the piston ring gap may be insuf ficient. I would suggest using a minimum of .015 end clearance.

When ring breakage cannot be traced to worn piston ring grooves, or some ob-. vious fault, the ends of the broken ring should be examined. Presence of a shiny spot at each end of the ring indicates in sufficient ring gap.

A TRIUMPH IN TROUBLE

I am the owner of a 1958 Triumph TR-6 650cc, which has been giving me nothing but trouble. After reading your column several times in CYCLE WORLD, I hope you will be able to give me some advice. My two major troubles are the clutch and the lubrication system. The clutch trouble is that my bike uses up clutches at an unbelievable rate. The trouble is always the same, too. The clutch driving tangs wear out. Can you advise me as to getting this problem corrected as I am going broke buying clutches.

The other trouble is a real beauty. I can't drive over 70 miles continuously without oil starting to leak out of the crankcase breather tube. Dealers tell me it is the oil pump that gets clogged, but wizen I get it replaced or cleaned, the same trauble still results on my first trip, it leaks bad only when the engine is running, at a very steady rate.

A2C Richard Toolin Little Rock AFB, Arkansas

The abnormal clutch plate wear you are experiencing may be traced to a worn clutch chain wheel. The slots in the chain wheel, into which the lined plates fit, should have a smooth thrust surface. If this surface has the appearance of a dull saw blade, the clutch wheel should be re placed. When wear is not too severe. these surfaces can be filed smooth. Filing these slots, however, will only be a temporary repair.

reason or this band condition the chain Clutch plate wear will also occur if the thin steel band around the outside of the chain wheel has for some another been removed. Without the outer hub can flex. If this exists, a band must be fitted or wheel replaced.

Oil loss through the crankcase breather tube can be the result of too much oil in the sump. This would mean a malfunction in the oil return system. Naturally, the oil pump is suspect, primarily because it is easy to get at and the most likely item to give trouble.

You stated that the pump was replaced. Was it a completely new pump or just pump parts? Since pump bodies and plungers do wear out, a complete new pump assembly should be tried. Due to the design of the Triumph pump, foreign matter in the oil can cause trouble. Undoubtedly the oil has been changed, but it should still be inspected, for the presence of metal in particular. Small pieces of metal in the oil, besides having a bad effect on the pump, indicate a more serious problem somewhere in the engine room. This possibility should not be overlooked since the problem is recurring.

(Continued on page 24)

The oil sump pickup tube should also be checked for leakage. This can be done with the oil pump removed. With an air hose held against the tube (at the sump end) and your finger over the return opening, the sound of any leakage can usually be detected. If leakage exists, either at the point where the pickup tube enters the crankcase, or through a fracture of the tube itself, the tube must be replaced. This will require dismantling the engine.

Oil loss from the engine breather can come from two other sources. Extremely worn piston rings and cylinder bores may be creating too much pressure in the lower end, or the crankcase breather itself could be at fault. This is a timed disc-type breather and normally quite trouble-free. It is located on the primary chain end of the intake camshaft.

Two distant possibilities concern the breather. If the machine has recently been rebuilt, the breather disc may have been left out. Or the driving fingers that fit in the end of the camshaft could have been broken when the crankcase halves were assembled. Assuming the lower end has received no major work, a problem here is remote.

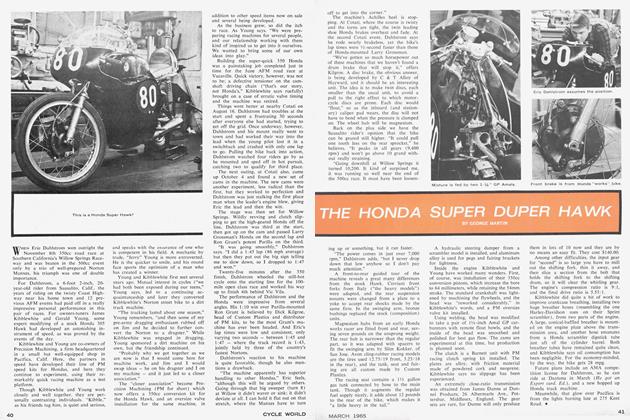

POOF NO LIGHTS

What makes my new Super Hawk burn up light bulbs? My Honda is only two months old, but I have replaced the tail light countless times. Every time I make a quick trip through the gears, the bulb blows. The dealer who sold me the Hawk claims it is vibration, but I can think of a dozen Hondas that don't have this trouble.

Bobby Pecat Ennis, Texas

Troubles of this sort can usually be traced to a loose connection somewhere in the system, faulty battery, defective rectifier, or rectifier ground. Determining condition of the battery and rectifier can only be done with the proper equipment and by someone familiar with the procedures required, namely the dealer.

A loose or poorly soldered wire terminal at the battery, light switch, or head light high/low switch can cause light bulb failure. All wire connections at these points should be carefully inspected. The possibility of a bare wire, particularly where the high/low switch wiring loom enters the handlebars, must not be overlooked. The AC electrical system has been developed to the point where failures are not too common. However, test equipment that the average owner does not have is necessary to locate a problem if one should occur. The easiest and cheapest thing to do when a problem like this arises is to have the work done by a reputable mechanic.

IT STAYS ON

I was hoping that you could help me locate the trouble in my 1963 H-D FL Duo-Guide. None of the local H-D shops have been able.

Electrical difficulty: At all engine speeds above slow idle, the generator "idiot light" is out. With headlight "on" the generator warning light glows dimly at all engine speeds above a fast idle. However, it quickly goes out when the engine drops to a fast idle (tjiis condition is only visible when riding at night). Could generator output be increased to remedy, or is the voltage regulator at fault? How can I check it and what is the best procedure to follow?

Harvey Ramsey Windfall, Indiana

To determine the amount of current being supplied the battery, clip one side of an ammeter to the negative terminal of the battery. Then ground the other side of the ammeter to the frame. As the engine speed is increased (with lights on) a reading of at least 1 amp on the plus side of the meter should show 3 to 5 amps. (If the readings appear to be backwards, reverse the ammeter leads.)

Action of the meter needle should also be noted. If there is extreme needle fluctuation at higher engine rpm, this may be due to sticky generator brushes, worn or dirty generator commutator, or a defective voltage regulator. Any of the aforemen tioned causes could result in the generator indicator light remaining on. This type of DC system is designed to draw the neces sary amount of power needed by means of the voltage regulator.

(Continued on page 26)

It the ammeter readings appear fligfl enough, and the needle is reasonably steady, the trouble may be in or at the switch itself. By removing the panel that houses the switch and speedometer, the switch connectors can be checked for looseness. If malfunctions of the generator and regulator are ruled out, a new switch should be tried.

Assuming the ammeter readings are low, the generator brushes and springs should be checked and thoroughly cleaned. The condition of the commutator must also be noted and any oil or grease removed. Each serration in the commutator seg ments should be cleaned of all foreign matter. This can be done with a pocket knife or a hacksaw blade sharpened to a point.

If there is any doubt as to the condition or trueness of the commutator, the gener ator should be disassembled and the arma ture turned in a lathe. Distortion of the commutator will result in brush float which at high rpm reduces the generator's efficiency. The inexperienced mechanic should refrain from trying to adjust the voltage regulator. Any adjustments at this point should be done by someone quali fied for this phase of work.

HEAVENS NO

In May of 1964, 1 was pleased to re ceive from you, in reply to my letter, an swers to my question on how to increase top end, etc., in which you stated "the Matchless G-12 is indeed a fine machine."

I am just now getting around to tearing it down, but in your road test of the Matchless G-15 CSR in the first para graph there is some reference to my ma chine blowing up all the time. (?) Would you mind going into this more thoroughly because 1 see no reason to spend the money I plan to on it if it's going to blow up. It's a 1961 G-12. Exactly what blows up and can it be replaced before this happens, or should I just trade it in on a H-D?

L. L. Smoot North HiRhiands, Calif.

There were some lower end problems encountered in the 1959-1960 G-12 models. Rod failure was prevalent on ma chines used for various high speed com petition events. This was caused for the most part by the connecting rod's being fitted too loosely at the factory. It was corrected on later models and these ma chines have won many demanding events.

When there has been a major engine failure, such as a seized rod, a little in vesigation will many times show that there was an outside cause, such as a broken oil line, dirty oil filter or the machine being allowed to run out of oil. These are things a person normally won't hear about. It's much easier to blame the machine than its human counterpart.

View Full Issue

View Full Issue