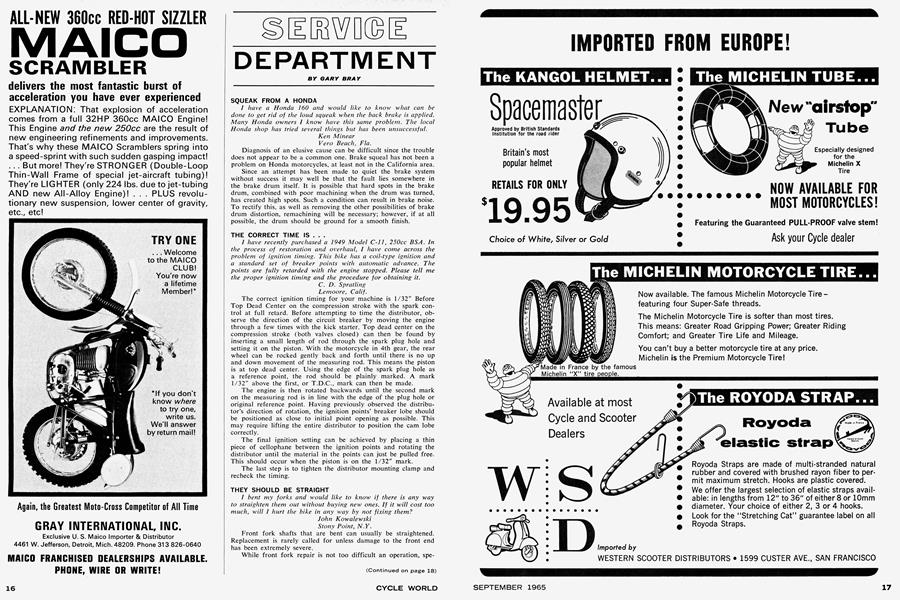

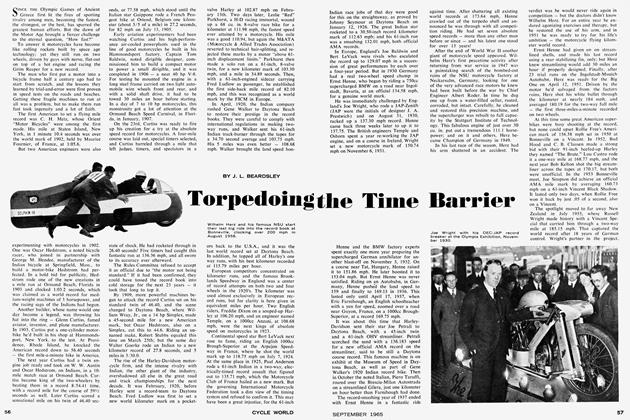

SERVICE DEPARTMENT

GARY BRAY

SQUEAK FROM A HONDA

I have a Honda 160 and would like to know what can be done to get rid of the loud squeak when the back brake is applied. Many Honda owners I know have this same problem. The local Honda shop has tried several things but has been unsuccessful.

Ken Minear Vero Beach, Fla.

Diagnosis of an elusive cause can be difficult since the trouble does not appear to be a common one. Brake squeal has not been a problem on Honda motorcycles, at least not in the California area.

Since an attempt has been made to quiet the brake system without success it may well be that the fault lies somewhere in the brake drum itself. It is possible that hard spots in the brake drum, combined with poor machining when the drum was turned, has created high spots. Such a condition can result in brake noise. To rectify this, as well as removing the other possibilities of brake drum distortion, remachining will be necessary; however, if at all possible, the drum should be ground for a smooth finish.

THE CORRECT TIME IS . . .

I have recently purchased a 1949 Model C-ll, 250cc BSA. In the process of restoration and overhaul, I have come across the problem of ignition timing. This bike has a coil-type ignition and a standard set of breaker points with automatic advance. The points are fully retarded with the engine stopped. Please tell me the proper ignition timing and the procedure for obtaining it.

C. D. Spratling Lemoore, Calif.

The correct ignition timing for your machine is 1/32" Before Top Dead Center on the compression stroke with the spark control at full retard. Before attempting to time the distributor, observe the direction of the circuit breaker by moving the engine through a few times with the kick starter. Top dead center on the compression stroke (both valves closed) can then be found by inserting a small length of rod through the spark plug hole and setting it on the piston. With the motorcycle in 4th gear, the rear wheel can be rocked gently back and forth until there is no up and down movement of the measuring rod. This means the piston is at top dead center. Using the edge of the spark plug hole as a reference point, the rod should be plainly marked. A mark 1/32" above the first, or T.D.C., mark can then be made.

The engine is then rotated backwards until the second mark on the measuring rod is in line with the edge of the plug hole or original reference point. Having previously observed the distributor’s direction of rotation, the ignition points’ breaker lobe should be positioned as close to initial point opening as possible. This may require lifting the entire distributor to position the cam lobe correctly.

The final ignition setting can be achieved by placing a thin piece of cellophane between the ignition points and rotating the distributor until the material in the points can just be pulled free. This should occur when the piston is on the 1/32" mark.

The last step is to tighten the distributor mounting clamp and recheck the timing.

THEY SHOULD BE STRAIGHT

1 bent my forks and would like to know if there is any way to straighten them out without buying new ones. If it will cost too much, will 1 hurt the bike in any way by not fixing them?

John Kowalewski Stony Point, N.Y.

Front fork shafts that are bent can usually be straightened. Replacement is rarely called for unless damage to the front end has been extremely severe.

While front fork repair is not too difficult an operation, special equipment is required that the average rider does not have access to.

(Continued on page 18)

Bent forks can create unstable handling characteristics which may not become apparent until hard braking, or a quick maneuver to avoid something, is called for. Since your safety depends on a sound and stable machine, I would have the front end inspected by an experienced mechanic. Most motorcycle dealers have facilities for this service.

FLUCTUATION

1 recently bought a new 1965 Triumph 200cc single-cylinder model T-20 SH and I cannot seem to get the carburetor to idle properly. It either idles too fast or too slow and stalls. 1 have had this machine back to the dealer four times and he says there is nothing wrong with it, but it is very annoying when it spits through the carburetor and stalls in heavy traffic.

The throttle needle is in the second notch from the bottom and 1 have adjusted the idling screw and air mixture, which seems to help some, but does not get rid of the stalling entirely. 1 hope you can help me with this problem.

Another problem 1 have is that a knock has started in the engine. 1 work in a garage and the mechanic there said he thought it was the piston knocking. 1 took it back to the dealer and he said there was nothing wrong with the engine. As 1 was not satisfied with what he said 1 took off the head and cylinder and the piston was quite loose in the cylinder. 1 could push a No. 8 feeler gauge down between the cylinder wall and piston to the first ring which 1 think has too much clearance.

1 would like to know if you think I should bore out the cylinder and put in a bigger piston. Since 1 took apart the engine the guarantee is over, so 1 will have to fix it on my own.

If you think it should be bored out, what size piston should be used and what clearance should it have? This machine has only 825 miles on it and I have not driven it too fast or let it run out of oil, so what do you think could have started the piston to knock? 1 think the piston must have been fitted too loose to start with.

Bill Murray Ont., Canada

The Triumph T-20 and machines equipped with similar automatic spark control mechanisms will experience idle fluctuation if there is a tendency for the spark control unit to stick or be anything less than free in operation. A thorough cleaning of the spark control assembly followed by lubrication with one or two drops of light oil will usually remedy the trouble. Since attention to the spark advance unit requires removal of the contact breaker point plate, the ignition timing should be checked and reset upon reassembly, if necessary.

Correct ignition timing should be 1/64" B.T.D.C. on the compression stroke with the automatic spark control in the full retard position.

The proper piston clearance for this motorcycle is .0035 thousandths if a careful break-in period is to be observed. For competition or hard running, piston clearance should be .0055.

(Continued on page 20)

It is possible that this machine came from the manufacturer with excessive piston clearance, particularly if the piston shows no signs of seizure. While .008 piston clearance is excessive, it must be pointed out that these machines are somewhat noisy in operation. To determine if a rebore is called for, the cylinder should be measured with a micrometer and compared with a new standard size piston. If excessive clearance does exist between the new piston and cylinder bore, then the cylinder should be bored for the first oversized piston.

SAGEBRUSH

Do you think that catching a large piece of sagebrush could cause the mainshaft or bearing to either bend or break on a 250cc Honda? Have you heard of the bearing going out on the main shaft of the transmission? Do you think that the bearing was bad to start with?

Leonard Bisel Yakima, Washington

A sudden jamming of the drive train by brush or other foreign matter will usually result in damage to the running gear at some point. If this situation has ever happened to a machine it would be the most logical reason for transmission bearing or shaft failure.

WHOA

/ am new to motorcycling, purchasing my first bike about a month ago. It is a 1957 NSU Super-Fox 125cc. 1 have bought CYCLE WORLD regularly since last fall, hoping that 1 would buy a bike this spring, and have been trying to learn a little about bikes in general before I actually got one of my own. I was lucky enough to get an owner’s manual, a quite complete handbook, but it is written in French. The lights did not work when I got the bike so with the aid of the diagram in the manual 1 rewired the bike and everything works fine now.

1 have one problem, maybe it’s only my ignorance of cycles, but how do 1 turn off the engine? 1 assumed it was like an auto engine where the ignition is turned off. But on this bike 1 turn the key of the switch to the right to start it (to turn on the battery), then turn it to center position to run, and to the left to turn on the lights. So all three positions have the ignition on, right?

As far as 1 can tell I followed the wiring diagram exactly with the exception that 1 installed a hidden toggle switch between the battery and ignition switch, but that shouldn’t have anything to do with it. So far 1 have been putting it in fourth and engaging the clutch to kill it, but it doesn’t seem right. Can you help this poor, green cyclist turn off his engine?

William B. Robinson Lawrence Univ. Appleton, Wise.

To start a motorcycle equipped with this type of ignition switch the key is pushed down, but remains in a neutral or center position for running without lights. Engine operation is brought to a halt merely by pulling the key up. The other two switch positions are for lights. The headlight is turned on by moving the key to the left. Rotation of the key to the right turns on the parking light.

(Continued on page 22)

In this country what we term a parking light is in many cases used as a running light in Europe for city or town riding. Since our traffic laws require that the main headlight be used at all times this switch position can be disregarded. A hidden ignition switch won’t affect the system.

If you need an owners’ manual printed in English or information on parts availability write to Cycle Products of USA, 80 Brand Street, Boston, Mass.

COLD AIR

1 have a CB-160 Honda and I wish to put crossover pipes on it. Some people say that if you put straight pipes on without making any other adjustments, it will hurt the engine. Some people say if you put long pipes on, the cold air won’t warp your valves but if you put on short pipes it will, and some people say it will also hurt your machine. Please answer these questions.

Marc Richter El Dorado, Kansas

Installation of crossover pipes on your CB-160 should require no more than minor adjustments to the carburetor. A slightly richer main jet and higher slide needle position may be necessary.

In order for exhaust valve damage to occur through use of too small an exhaust system, the pipes would have to be extremely short, so short in fact that the motorcycle would suffer a drastic reduction in performance. The use of straightthrough crossover exhaust pipes at least 35" in length will cause no damage to the exhaust valves.

NO PROBLEM

1 recently bought a used 1963 Honda scrambler with a 305cc engine and Harman & Collins racing cam, valve springs and oversize valves. 1 use it mostly around the city but tour the country as often as possible. This summer a friend and 1 plan to tour the Sierras for a month. Would running the engine between 3,000 and 6,000 rpm hurt the engine? If so, how can 1 avoid it without winding it out all the time? 1 would appreciate any suggestions and information about the situation.

Joseph Tone San Francisco, California

No problems should be encountered in operating your Honda from 3,000 to 6,000 rpm. Since these motorcycles seem happiest at high rpm, 3,000 rpm is the minimum I would use.

HEAD GASKET PROBLEMS

Once before 1 wrote you concerning problems with my 1949 Ariel Square Four. Now I have another problem. 1 keep blowing head gaskets. 1 take the usual precautions when installing a new set but they don’t hold.

Do you know of a special gasket material or a ready made gasket 1 can buy? Any help you can give will be greatly appreciated.

R. S. Powell Logan, W. Va.

Head gasket failure has been a chronic problem on the early alloy head Ariel Square Four. The difficulty unfortunately is one of general design, and a cure can be both expensive and time consuming. Replacement of the 5/16" diameter cylinder head hold-down studs with 3/8" studs is necessary for a permanent seal at the cylinder and cylinder head joint. The eight 5/16" studs located in the center of the cylinder need not be increased in size. They should, however, be carefully inspected for faulty threads or any indication that they are pulling out of the cylinder.

Heli-coils (5/16") should be installed if there is evidence that the studs are pulling out. The cylinder finning around each holddown nut should be relieved to facilitate starting the nut on the stud. There are also 3/8" nuts which have a small hex, available in both inch and Whitworth sizes. This type of nut makes it possible to use the larger stud whereas a conventional 3/8" nut would not fit the small space provided in the cylinder.

Both the cylinder and cylinder head must be resurfaced along with the stud change to make the cure complete. To carry out this work properly, accurate workmanship and machine shop facilities are essential.

View Full Issue

View Full Issue