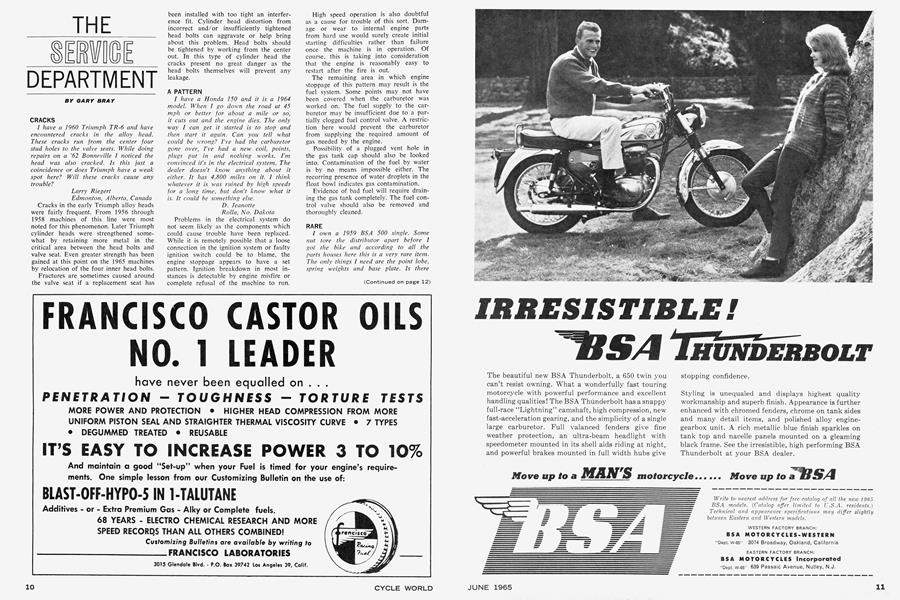

THE SERVICE DEPARTMENT

GARY BRAY

CRACKS 1 have a I960 Triumph TR-6 and have encountered cracks in the alloy head. These cracks run from the center four stud holes to the valve seats. While doing repairs on a '62 Bonneville I noticed the head was also cracked. Is this just a coincidence or does Triumph have a weak spot here? Will these cracks cause any trouble? Larry Riegert Edmonton, Alberta, Canada

Cracks in the early Triumph alloy heads were fairly frequent. From 1956 through 1958 machines of this line were most noted for this phenomenon. Later Triumph cylinder heads were strengthened somewhat by retaining more metal in the critical area between the head bolts and valve seat. Even greater strength has been gained at this point on the 1965 machines by relocation of the four inner head bolts.

Fractures are sometimes caused around the valve seat if a replacement seat has been installed with too tight an interference fit. Cylinder head distortion from incorrect and/or insufficiently tightened head bolts can aggravate or help bring about this problem. Head bolts should be tightened by working from the center out. In this type of cylinder head the cracks present no great danger as the head bolts themselves will prevent any leakage.

A PATTERN I have a Honda 150 and it is a 1964 model. When 1 go down the road at 45 mpli or better for about a mile or so, it cuts out and the engine dies. The only way 1 can get it started is to stop and then start it again. Can you tell what could be wrong? I've had the carburetor gone over, I've had a new coil, points, plugs put in and nothing works. I'm convinced it's in the electrical system. The dealer doesn't know anything about it either. It has 4,800 miles on it. I think whatever it is was ruined by high speeds for a long time, but don't know what it is. It could be something else. D. Jeanotte Rolla, No. Dakota

Problems in the electrical system do not seem likely as the components which could cause trouble have been replaced. While it is remotely possible that a loose connection in the ignition system or faulty ignition switch could be to blame, the engine stoppage appears to have a set pattern. Ignition breakdown in most instances is detectable by engine misfire or complete refusal of the machine to run.

High speed operation is also doubtful as a cause for trouble of this sort. Damage or wear to internal engine parts from hard use would surely create initial starting difficulties rather than failure once the machine is in operation. Of course, this is taking into consideration that the engine is reasonably easy to restart after the fire is out.

The remaining area in which engine stoppage of this pattern may result is the fuel system. Some points may not have been covered when the carburetor was worked on. The fuel supply to the carburetor may be insufficient due to a partially clogged fuel control valve. A restriction here would prevent the carburetor from supplying the required amount of gas needed by the engine.

Possibility of a plugged vent hole in the gas tank cap should also be looked into. Contamination of the fuel by water is by no means impossible either. The recurring presence of water droplets in the float bowl indicates gas contamination.

Evidence of bad fuel will require draining the gas tank completely. The fuel control valve should also be removed and thoroughly cleaned.

RARE I own a 1959 BS A 500 single. Some nut tore the distributor apart before I got the bike and according to all the parts houses here this is a very rare item. The only things 1 need are the point lobe, spring weights and base plate. Is there any distributor that is interchangeable with this one? Also, could a magneto be adapted to this machine? If so, what kind? Tollie J. Perry Virginia Beach, Va.

(Continued on page 12)

SVC. DEPT.

The parts needed for this machine may be rare but they should be available through either a franchised BSA dealer or from a Lucas parts depot. Installation of other than the original type distributor would more than likely create a mounting or gear alignment problem.

Distributors similar to the one used on this machine are fitted to other brands of English motorcycles. However, these components are also produced by Lucas and the problem of their availability would still remain. If there is no dealer in your area or if he is for some reason unable to help you, write BSA Inc., 639 Passaic Avenue, Nutley 10. New Jersey. They should be able to direct you to a dealer or parts house that can fill your needs.

Installation of a Lucas KNCI (423 48D) or BSA part #19-1219 magneto is possible.

Such an undertaking will also require two magneto hold-down straps, part #65-1423, #65-1425 and magneto drive gear #65-1879. An oil seal (#65-2316) normally located behind the magneto gear is also called for; however, due to a slight difference in machining the crankcase for the distributor mount, it may be necessary to fit a seal between the magneto and crankcase rather than behind the gear. I must add that while this change is possible, a new magneto is quite expensive.

EVEN WITH THE FAN IT'S HOT In June of 1963 1 bought a new Allstate compact scooter. Since then it has been running fine until last fall. Then it began acting as if it were being run too long, for it would overheat. I can't understand this because the engine is cooled by a radial blower, which keeps a steady stream of air running across the cylinder. But it doesn't matter what I do — the scooter still overheats after about five minutes of running. I keep the spark plugs clean and gauged right so it couldn't be that.

Could you tell me what the trouble is? Also could you tell me how I can get more horsepower and more speed out of the engine without very much modification? It is powered by a 59cc two-cycle with a bore of 43mm and a stroke of 43mm and has a compression ratio of 8:1. Carburetion is by a Bing 17mm carburetor. 1 would appreciate any help you could give me. Mike Holder Chesterland, Ohio

Overheating and loss of power from your machine may be due to incorrect ignition timing or a restriction in the exhaust system. The ignition timing should be checked and reset if necessary. This information is contained in your owner's manual. The exhaust port and muffler should be thoroughly cleaned of carbon deposits. Carbon build-up over a period of time will gradually reduce the amount of escaping exhaust gases. Any great increase in power usually means more than minor changes in this type of engine. Performance may be increased somewhat by polishing the exhaust, transfer, and intake ports. Milling the cylinder .020 to raise the compression will also help.

(Continued on page 14)

SVC. DEPT.

OILY HANDS I have a 1960 BSA Super Rocket. I have just had the engine rebuilt: new rings, wrist pins, bore job, new pistons, valves and valve guides. All these parts are stock BS A parts. They were all fitted by an authorized BS A mechanic. The only difference is that the cylinder barrels are off a 1957 BS A Super Rocket. It blows smoke so bad that when you put your hands by the exhaust pipes they become soaked with oil. What could possibly be wrong? The rings are not cracked. Dennis B. Worth Chicago, Illinois

The problem of excessive smoke and heavy oil consumption after engine rebuilding is naturally confusing, as there appears to be no obvious reason for such goings on. The earlier BSA cylinder will have no effect on oiling, as long as the top end oil return passageways are clear and the bores themselves are true and undamaged. Conditions under which oiling occurs may help give some clue to the cause.

When smoke is present upon starting the engine, and does not diminish after running for a short time, lack of proper oil control from inefficient or faulty piston rings seems the likely answer. It is possible through a manufacturing error that the rings used in your machine have inadequate tension. The standard BSA oil ring also has a rather wide scraping surface. This can create difficulties if the replacement pistons are the higher compression variety. Use of oil rings with sharper scraping areas (such as Hepolite) will give better oil control.

Poor crankcase scavenging as the result of a malfunction somewhere in the oil return system cannot be overlooked. However, if work to the engine has been confined to the upper end alone, trouble in the lubrication system is unlikely.

Large quantities of oil issuing from the crankcase breather would indicate some form of trouble here. In the event this oiling condition does not appear until the engine has reached operating temperature, I would suspect something amiss at the valve guides. The replacement guides may have insufficient fit in the cylinder head. Head expansion can allow oil to travel into the ports between cylinder head and valve guide if the fit is not tight enough. In an aluminum head this condition can be further aggravated if cast iron valve guides have been used in place of the stock bronze guides. Bronze guides should have at least .001 interference, cast iron guides slightly more.

A crack in the head into the intake port from the valve spring chamber cannot be ruled out either. To determine the presence of a crack in the cylinder head, it should be dye-checked and welded if necessary.

ADD THE SINK I have a question that no one around here seems to know much about. I own a '61 Triumph Tiger Cub with a 3A cam, big valves; you know, it's one of those engines with everything but the kitchen sink in it. What I want to know is can I put a carburetor from, say, a BSA 650 twin on it? If this is possible how might I go about installing this little goodie? Dick Tyson Weirton, W. Va.

Use of the larger BSA carburetor is possible without too much difficulty, providing it is no larger than 1 1/16". With this size carburetor there will be sufficient material in the cylinder head and manifold to allow matching the port and carburetor without sacrificing strength. When increasing the port size, caution should be exercised in the area just behind the intake valve guide. It is possible to go through into the valve spring chamber at this point if too much metal is removed.

Gradually tapering the intake port outward to 1 1/16" where the manifold and carburetor join should produce the best results. While even a larger carburetor (up to 1 3/16") could be mounted, two undesirable effects may be encountered: unless reinforced, the intake manifold will be weakened by removal of metal necessary to match the port and carburetor. The larger carburetor itself may be too big, causing poor all-around performance. •

View Full Issue

View Full Issue

More From This Issue

-

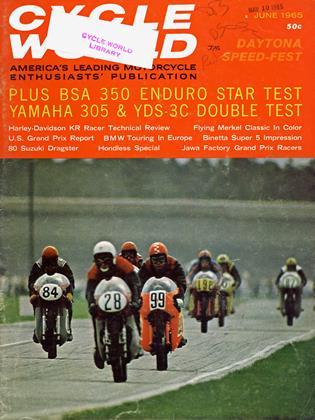

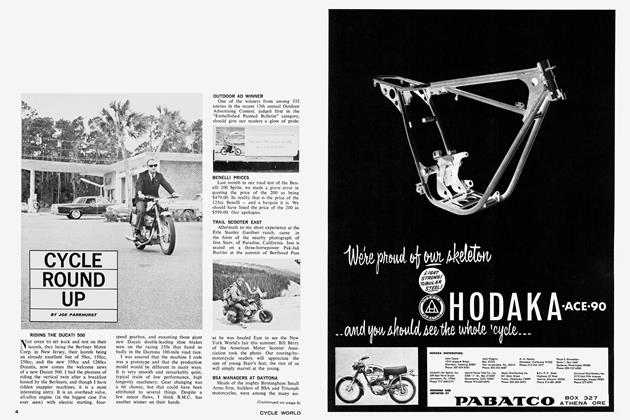

Cycle Round Up

June 1965 By Joe Parkhurst -

[technicalities]

June 1965 By Gordon H. Jennings -

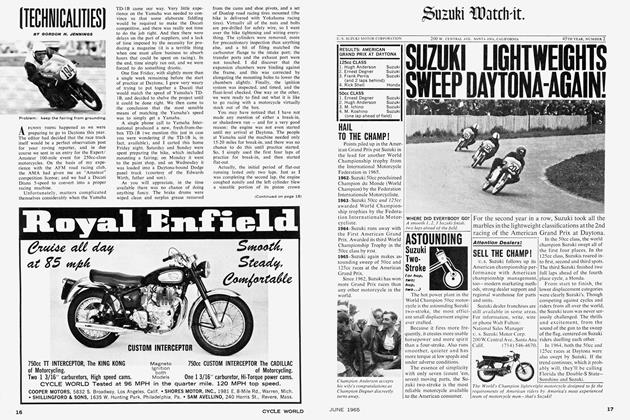

Suzuki Watch-It.

Suzuki Watch-It.Suzuki Lightweights Sweep Daytona-Again!

June 1965 -

Letters

LettersLetters

June 1965 -

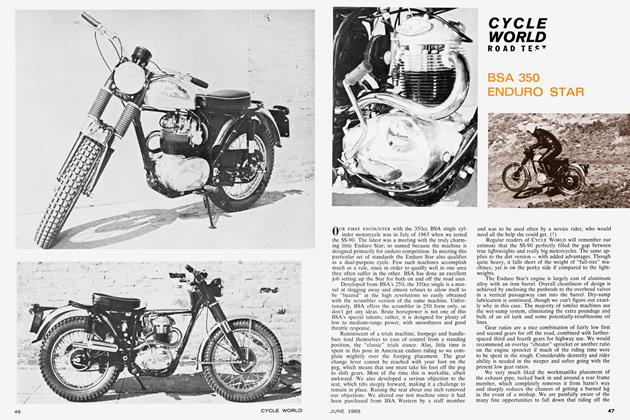

Cycle World Road Test

Cycle World Road TestYamaha 305 Ym-1 & Big Bear Scrambler

June 1965 -

Cycle World

Cycle WorldRoad Test Bsa 350 Enduro Star

June 1965