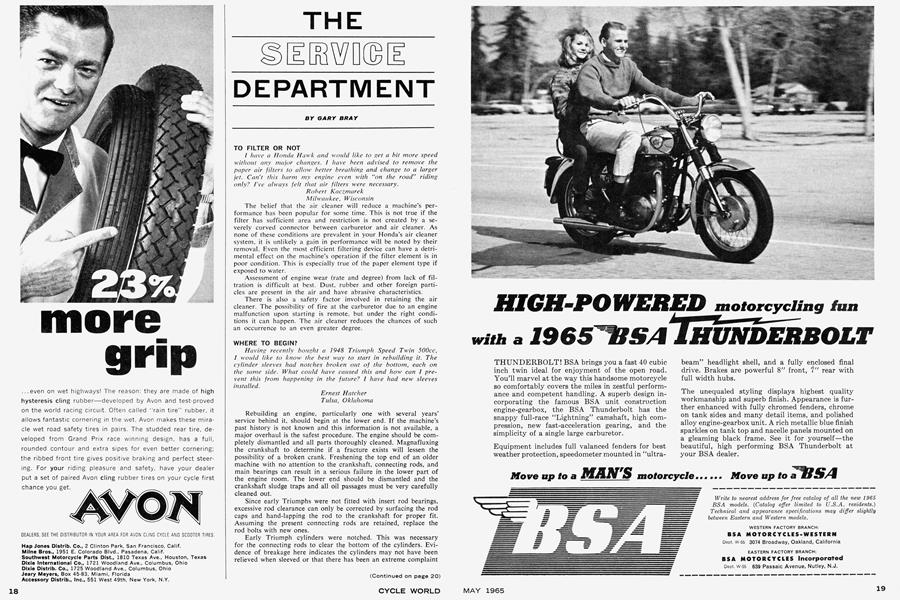

THE SERVICE DEPARTMENT

GARY BRAY

TO FILTER OR NOT

I have a Honda Hawk and would like to get a hit more speed without any major changes. I have been advised to remove the paper air filters to allow better breathing and change to a larger jet. Can’t this harm my engine even with “on the road” riding only? I’ve always felt that air filters were necessary. Robert Kaczmarek Milwaukee, Wisconsin

The belief that the air cleaner will reduce a machine’s performance has been popular for some time. This is not true if the filter has sufficient area and restriction is not created by a severely curved connector between carburetor and air cleaner. As none of these conditions are prevalent in your Honda’s air cleaner system, it is unlikely a gain in performance will be noted by their removal. Even the most efficient filtering device can have a detrimental effect on the machine’s operation if the filter element is in poor condition. This is especially true of the paper element type if exposed to water.

Assessment of engine wear (rate and degree) from lack of filtration is difficult at best. Dust, rubber and other foreign particles are present in the air and have abrasive characteristics.

There is also a safety factor involved in retaining the air cleaner. The possibility of fire at the carburetor due to an engine malfunction upon starting is remote, but under the right conditions it can happen. The air cleaner reduces the chances of such an occurrence to an even greater degree.

WHERE TO BEGIN?

Having recently bought a 1948 Triumph Speed Twin 500cc, I would like to know the best way to start in rebuilding it. The cylinder sleeves had notches broken out of the bottom, each on the same side. What could have caused this and how can I prevent this from happening in the future? I have had new sleeves installed. Ernest Hatcher Tulsa, Oklahoma

Rebuilding an engine, particularly one with several years’ service behind it, should begin at the lower end. If the machine’s past history is not known and this information is not available, a major overhaul is the safest procedure. The engine should be completely dismantled and all parts thoroughly cleaned. Magnafluxing the crankshaft to determine if a fracture exists will lessen the possibility of a broken crank. Freshening the top end of an older machine with no attention to the crankshaft, connecting rods, and main bearings can result in a serious failure in the lower part of the engine room. The lower end should be dismantled and the crankshaft sludge traps and all oil passages must be very carefully cleaned out.

Since early Triumphs were not fitted with insert rod bearings, excessive rod clearance can only be corrected by surfacing the rod caps and hand-lapping the rod to the crankshaft for proper fit. Assuming the present connecting rods are retained, replace the rod bolts with new ones.

Early Triumph cylinders were notched. This was necessary for the connecting rods to clear the bottom of the cylinders. Evidence of breakage here indicates the cylinders may not have been relieved when sleeved or that there has been an extreme complaint from the lower engine compartment sometime in the past. Before final engine assembly, fit the crankshaft with rod and piston attached to the drive side crankcase. The cylinder should then be set in place. Rotation of the crankshaft assembly will enable you to determine at what point the cylinder must be relieved for ample rod clearance. In rebuilding any powerplant one must remember that metal gets tired. Restoration of a machine of this vintage should not be limited to the engine alone. All components comprising running gear should be carefully inspected and any faults remedied.

(Continued on page 20)

AN OLD TIMER

1 am asking a question that is probably of little interest to 99% of your readers but it is very important to my son and myself. He has developed a strong interest in cycles since 1 have been using one again (after 20 years) for work and for pleasure. Somehow he has dug up enough parts to put an old Harley-Davidson (Model ’35 VLD) into what appears to be first class shape. It is about ready to run except, how does the oil return function? We can see nothing but crankcase pressure” to do the job. If our assumption is correct, is this method a positive one? Ray B. Glaseo Inverness, Florida

The lubrication system of the H-D VL is the total loss type. Oil is pumped into the engine, used and burned off. The amount of oil needed by the powerplant is regulated by the pump and throttle being connected. More rpm, more oil. For hard riding the oil supply can be increased by an occasional shot from the manual hand pump mounted on the oil tank. Seventy-weight oil should be used for engine lubrication as the VL tends to run hot and lighter oil will run through too quickly. By today’s standards this machine is considered primitive. Strange, but every now and then I see one on the highway. It may be possible to purchase a workshop manual by writing to the Harley-Davidson Motor Co., Milwaukee 1, Wisconsin.

IT WON'T FIT

/ own a Honda 150 and would like to know if there is some way to put a new Honda CB-160 cylinder block on to give me a dual curb setup. If so, how much of a difference would it make? Also, if 1 put in a full race cam would it greatly improve my performance when entered in local dirt track racing? What modifications would you recommend for this type racing? Bob Stoker Colorado Springs, Colo.

The Honda CB-160 cylinder and cylinder head cannot be adapted to the CA-95. Biggest reason against this change is the difference in camshaft drive location. Installation of dual carburetors is possible, but modifications of this sort require extensive inlet port alteration and machine work. Specialized work of this nature is very expensive.

Displacement of your CA-95 can be increased to 161cc by reboring for S4-150 pistons. If even more displacement is desired, Honda S4-160 pistons can be used. Approximately 167cc can be attained with this piston change. Care must be taken to insure there is no interference between piston and cylinder head if any of these piston combinations are used. Valve area can be increased by using modified Honda C-200 valves.

Smoothing of intake and exhaust ports should be carried out but best results will probably be obtained if the general shape of the ports is not altered. The ar^a from the valve guide can be enlarged outward to the valve seat in conjunction with the larger valves. Material around the valve guide can be smoothed or worked to give less resistance to gas flow, but under no circumstances should this support for the guide be removed.

To further increase performance of your CA-95, a YB921416B camshaft can be fitted. Assuming the dual carburetion idea has been dispensed with, good results can be obtained by replacing your present unit with a 22mm Super Hawk or scrambler mixing device. For high rpm competition, megaphones should be used. These are available from Honda, part numbers YB923961A and YB923962A.

The exhaust system should also be modified so that both pipes and megaphones are on the “off” side of the machine. This is of primary importance if the motorcycle is to be used for dirt track competition. A reasonably competitive machine is possible with these changes, coupled with careful and imaginative work.

(Continued on page 22)

CONSTANT DRIP

I have a Honda Trait 55 that leaks oil. There is a constant drip coming from underneath the engine near the exhaust pipe attachment. I have searched under there hut can’t find anything. Would you please tel! me how I can stop this? Randy Ruesch Beaver, Utah

External oil leaks can create a great deal of frustration in locating their point of origin. A thorough cleaning of the engine, followed by careful investigation in the general area of the leak, will usually enable the trouble to be pinpointed.

A continuous loss of oil beneath the machine at the exhaust pipe and muffler joint can be due to a faulty clutch case gasket or damaged kick starter seal. The possibility of a casting flaw or crack in the case must not be overlooked either.

Evidence of oil loss in the vicinity of the exhaust pipe and cylinder head joint can mean the pushrod tower or rocker box oil return passageway seals are defective. These seals are located between the cylinder and cylinder head joint, one 10.5mm O-ring for each pushrod and a 7.5mm O-ring for the oil return hole.

A broken cylinder base gasket, cracked or loose overhead oil supply line should also not be ruled out. If the leak is found at the cylinder base, all related top end seals should be renewed at the same time replacement of the base gasket is carried out. Use of gasket sealer or aluminum paint upon reassembly will insure a proper seal. The overhead oil line can be dealt with in three ways if found to be the villian — replaced, resoldered or, if cracked, it can be cut and a short length of rubber or plastic hose used to join the line.

DARK BLUE

I own a I960 Triumph T-110 and am concerned with induction hias. One side is running dark and the other light. Can you give me any information on this? The only thing I can think of is twin curbs. And next, l heard that a machine is running too rich if the exhaust pipes are a very dark blue at the head. Is there any truth in this? Don Smith St. Catharines, Ontario Canada

Discoloration of exhaust pipes close to the exhaust ports indicates excessive heat. A weak fuel mixture from an air leak in the induction system may be creating this problem. Incorrect ignition timing is also a possibility. Both should be looked into. I would carefully inspect the carburetor manifold gaskets at the manifold-cylinder head joint. Trouble is occasionally encountered at this point. Ignition timing should be 7/16" or 39° B.T.D.C. The magneto must be in a fully advanced position when checking or retiming is carried out. Play in the magneto armature may also be present. When this condition exists the point gap will vary and timing can be different for each cylinder. Check for magneto bearing play by placing a screwdriver under the point assembly fixing bolt and gently prying upwards. To eliminate bearing play, the necessary shims must be removed from between the main body of the magneto and the magneto end plate. The correct point gap is .012.

A STACK OF WASHERS

How far can the new unit construction 650cc Triumphs be over-bored? According to their literature, they have increased bolt centers to allow maximum rebore. We used to bore the old engine .125-over but there was practically nothing left between the pistons and the head bolts. As the saying goes, if you bore it out too far you won’t have anything left but a stack of washers. Harvey W. Read Racine, Wisconson

The new unit construction 40-inch Triumph can safely be over-bored 100 thousandths. Since there has been a relocation of the cylinder head hold-down bolts, it is likely that the cylinder could stand even more than .100-over, but cylinder distortion becomes more of a problem.

View Full Issue

View Full Issue