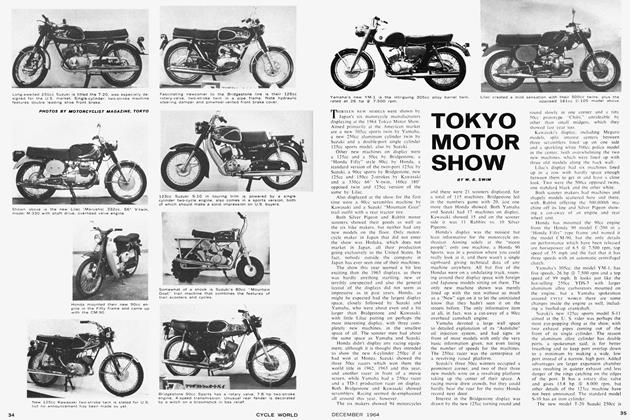

[TECHNICALITIES]

GORDON H. JENNINGS

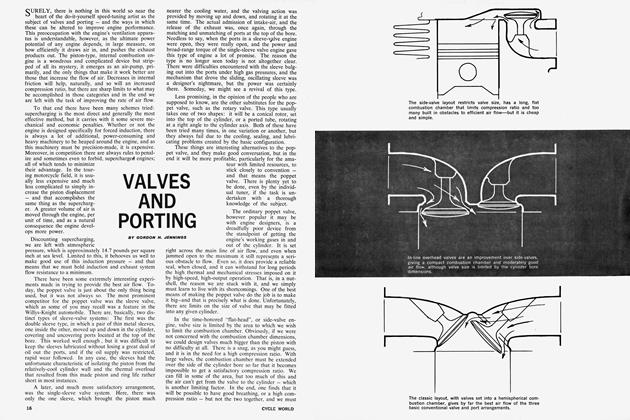

MANY YEARS AGO, no high-performance engine was considered complete unless it had a "double-valve" cylinder head, with two intake and two exhaust valves. Many of the sporting and racing automobiles had 4-valve cylinder heads, while in our own field, motorcycles, there were numerous examples of this valve layout. Among these was the famous Rudge, and there was even a 4-valve Triumph single, which had some success in TT-racing. However, it is interesting, and instructive, to note that the Triumph was redesigned as a two-valve engine, and in that version was faster than when it had the double-valve cylinder head.

Others had much the same experience with 4-valve cylinder heads, and in time the present 2-valve configuration became universal. Unfortunately, just as the 4-valve layout was put to rest permanently, up popped Honda with their 250cc racing “four." which has 4 valves per cylinder. The phenomenal performance of this machine has renewed interest in the 4-valve layout, and 4-cylinder heads are being planned for engines that will not benefit at all from the change. The truth is that the 4-valve per cylinder concept is not all that the Honda makes it appear to be.

The primary assumption that everyone makes with regard to the 4-valve cylinder head is that the two intake valves will flow more air than a single intake valve. If all the valves were the same siz.c. that would be true: however, when the valves have to be fitted into the space provided by some given cylinder bore, the valve heads must be drastically reduced in diameter when two intakes are used. In engines with “vertical" valves, the 4-valve layout will provide a slight increase in valve area over the conventional 2-valve arrangement. But. in virtually all motorcycle engines, and certainly in all racing engines. the valves have an inclined positioning in the cylinder head, and this is used in combination with a hemispherical combustion chamber, or some near equivalent. With this layout, it is virtually impossible to improve upon intake valve area by changing from one to two intake valves. Certainly, you can draw big dual intake valves, but making them work is quite ¡mother matter.

At first glance, it would appear that the greatest valve area would be provided by disposing the valves equidistant around the hemispherical combustion chamber. And, in fact, with the valves disposed in that fashion, it is possible to crowd in two 1.625" intake valves above a 5.5" cylinder bore. With the same cylinder diameter and a conventional 2-valve head, the single intake valve could not be much more than 2" in diameter. Obviously, this arrangement provides enormous valve area. Equally obvious (to anyone who has made a study of the problem) there is a snag: literally. With all the valves aimed straight in at the center of the combustion chamber, if more than a single valve opens, there will be trouble. With such big valves, the valve heads would clash just as soon as the valves lifted from their seats. And. with even a moderate amount of “overlap.” all four valve heads would jam together. It is, of course, entirely possibly to reduce the size of the valve heads until they no longer clash, but this is defeating the purpose of having the 4-valve — at least, from the point of valve area. Finally, there would be an extremely unhandy collection of moving metal around the valves if you tried to have them all standing out of the head at different angles. In the Rudge motorcycle engine, the exhaust valves were splayed out. but the intake valves’ stems were parallel. As ¡1 consequence, the intake actuating rocker system was perfectly straightforward — and a mass of rockers and walking-beams was required for the exhausts.

All of the better 4-valve cylinder heads have had one or more overhead camshafts, and ¡ill of them have carried their valves in a “pent-roof” combustion chamber. In this layout, the paired intake and exhaust valves have parallel stems, but each pair of valves is angled out to the side, usually 45-degrecs from the cylinder axis. Honda uses this arangement, and it has been used in the “Offy” Speedway and sprint car engines for years. The pent-roof layout gives the least complicated valve actuating mechanism, and does not restrict valve size unduly, but the two intake valves that can be stuffed into a pent-roof chamber will have no greater combined area than that of a single valve in a hemispherical combustion chamber — again assuming that the cylinder bore remains the same.

(Continued on page 20)

Actually, the pent-roof chamber’s dual intake valves can be made to have more area, but a loss in air flow capacity will result if they are made too big. The ends of the pent-roof chamber tend to shroud the valve heads, and the fact that the valves are set quite close together creates some mutual interference. If the valves are too large, with the edges of the valve heads too close to the sides of the combustion chamber, then the flow will actually be less than if the valve heads were somewhat smaller in diameter. In practice, when the size of the dual intake valves is adjusted to avoid crowding, the total valve area will be so close to the same as that of a single intake valve (over the same cylinder) that the difference isn’t worth mentioning.

Unfortunately, while the intake valve area may be the same for 2-and 4-valve cylinder heads, the air flow capacities are not. If there is to be any kind of streamlining inside the ports, then it will be necessary to have a bifurcated port shape, with a single, large port splitting in half at some point within the head and becoming two smaller ports. This means some changes in air flow, and it means that there will be more wall surface inside the port and, hence, more resistance to flow just from skin friction. The best port is round, for a circle contains the most area for any given circumference; the 4-valve head must depart considerably from this ideal.

Finally, there is all of the added flow resistance from having two valve stems and guides in the intake port. Valve stem diameter remains virtually constant (within the size range we are discussing) and when you add the extra intake valve, you have doubled the resistance to flow from the valve stem. In the end. you will find that the flow capacity of a 4-valve head is slightly inferior to that of a well designed 2-valve cylinder head.

Here, you may be wondering why Honda bothers with the 4-valve layout if it is, as I say, inferior. The reason is all wrapped up in the problems of high engine speeds. A big. single intake valve has a lot of mass, and is difficult to control with even very stiff valve springs. Two smaller valves, each with its own set of springs, will continue to function properly at much higher engine speeds. And that is the sole reason Honda employs the 4-valve cylinder head.

The modern trend toward short-stroke engines may produce a use for the 4-valve cylinder head even in relatively low speed engines. Take, as a hypothetical example, a 350cc single having equal bore and stroke dimensions (76mm x 76mm equals 345cc). Using a 45-degree inclination for the intake valve, we find that the biggest valve that can be accommodated would he no more than 1.75" in diameter — leaving a bit of room for the valve seat and clearance for “overlap” with the exhaust valve. If we assume that this hypothetical engine will he limited hy the strength of the piston, rod and crank assembly to a mean piston speed maximum of 4000 feet per minute, then our rev limit will be right at 8000 rpm. There are numerous examples of 1.75" intake valves that pop open and close at 8000 rpm without undue difficulty, so in this instance a single intake valve will do the job better than two. Our 76mm x 76mm engine would not be helped by a 4-valve cylinder head.

(Continued on page 22)

On the other hand, if we take the same 350cc single and give it radically different bore and stroke measurements, for example. 90mm x 55mm (3.54 x 2.16), the displacement remains essentially the same hut the situation changes drastically. At the same 4000 feet per second rate of piston speed, the engine's crank speed would have climbed to 1 1.000 rpm. At the same time, we are presented with much more room (because of the bigger bore) for the intake valve. Without crowding things unduly, it should be entirely possible to fit an intake valve 2.125" in diameter. However, as should be obvious, there is little hope that such a big valve could be made to work in conjunction with the I 1.000 rpm engine speed.

In the above instance, there is good reason for going to a 4-valve layout in the cylinder head. Where there is no means presently at our disposal for handling a 2.125" intake valve at 11.000 rpm. a pair of smaller valves present no such problem.

I would estimate that two 1.50" intake valves could be accommodated, and the combined areas of these would be 3.53 square inches. The area of the single. 2.125" intake valve is 3.54" square inches, so you can see that we have made no gain in area by using dual intake valves. But, by providing overhead camshafts and stiffish valve springs we can maintain control of a 1.5" valve at 11.000 rpm. while the onset of “float” with the 2.125" single valve would limit our hypothetical ultra-shortstroke engine to less than 9000 rpm. In this case, as in the Honda, we may rely on the added revs (2000 or more, with this example) to more than compensate for any deficiencies the 4-valve cylinder head may have with regard to flow capacity.

All things considered, it would seem safe to predict that we shall he seeing more of the 4-valve cylinder head — despite the fact that it is inferior to the 2-valvc arrangement with regard to gas flow. The trend is toward ever higher crank speeds, which makes valve float very much more a problem than it once was. At the Same time, the need for reliability at high crank speeds has led to big-bore/short-stroke engines — and this gives us room, at the top of the bore, for big valves. Big valves are difficult to control at high crank speeds, and that will bring about an overall trend toward 4-valve cylinder heads. Let me say just once more that this trend is not due to any improvement in “breathing” with the 4-valve head; it is all a question of valve gear dynamics.

![[technicalities]](https://cycleworld.blob.core.windows.net/cycleworld19641201thumbnails/Spreads/0x600/10.jpg)