Modifying The Jawa 250 For Road Racing

WE present this article for a very good reason: first, it gives those of our readers who own Jawas an excellent guide for any efforts the)' might feel inclined to put forth in the interest of increased engine output; second, the instructions cover virtually all of the accepted techniques for two-stroke modification work and the article is, there fore, of some interest and value to all. Also, the article may serve the incidental func tion of developing in the reader a proper appreciation for the truly formidable precision required for successful two-stroke hop-up work. There is, as one may readily see, a lot more to the "simple" two-stroke engine than immediately meets the eye.

AS YOU HAVE READ in the series on two-stroke engines, there are basic principles which may be applied for improving performance. Many of you wish to know how these principles can be applied to your individual machine. The following gives specific detailed methods for modifying the Jawa 250 engine for road racing. The modifications outlined here give methods for improving engine performance: First, porting will be modified for smooth flow of the fuel-air charge, and to adjust the intake, exhaust and transfer timing; second, the combustion chamber will be reshaped and the compression ratio raised. Third, a more efficient exhaust will be provided.

modifications should not be undertaken without careful consideration of the effort and expense involved. Considerable hand work must be done on the porting which requires patience, skill and care. Work on the port openings should be carried out to an accuracy of 1/64". Modifications to the cylinder head includes welding and machining to reform the combustion chamber. A new exhaust system must be accurately fabricated. The modifications will produce a substantial increase in power, but at the expense of engine life, and the machine will no longer be suited for street use. The

Jawa 250 uses the Schurle system of transfer porting with piston controlled intake. When modifications are complete, your engine will have a “squish” type combustion chamber and expansion chamber exhaust system. Compression ratio will be increased to 11:1. Modifications

may be carried out on any of the Jawa 250 two-stroke engines, but they are best done on the Jawa Trials or Scrambler engines which have aluminum instead of cast iron cylinders for better cooling. The

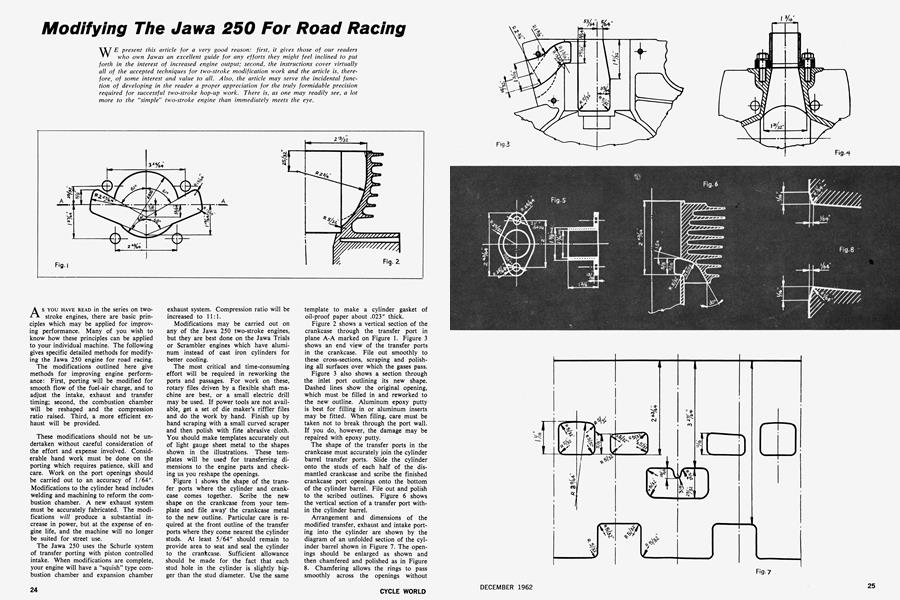

most critical and time-consuming effort will be required in reworking the ports and passages. For work on these, rotary files driven by a flexible shaft machine are best, or a small electric drill may be used. If power tools are not available, get a set of die maker’s riffler files and do the work by hand. Finish up by hand scraping with a small curved scraper and then polish with fide abrasive cloth. You should make templates accurately out of light gauge sheet metal to the shapes shown in the illustrations. These templates will be used for transferring dimensions to the engine parts and checking us you reshape the openings. Figure

1 shows the shape of the transfer ports where the cylinder and crankcase comes together. Scribe the new shape on the crankcase from your template and file away the crankcase metal to the new outline. Particular care is required at the front outline of the transfer ports where they come nearest the cylinder studs. At least 5/64" should remain to provide area to seat and seal the cylinder to the crankcase. Sufficient allowance should be made for the fact that each stud hole in the cylinder is slightly bigger than the stud diameter. Use the same template to make a cylinder gasket of oil-proof paper about .023" thick. Figure

2 shows a vertical section of the crankcase through the transfer port in plane A-A marked on Figure 1. Figure 3 shows an end view of the transfer ports in the crankcase. File out smoothly to these cross-sections, scraping and polishing all surfaces over which the gases pass. Figure

3 also shows a section through the inlet port outlining its new shape. Dashed lines show the original opening, which must be filled in and reworked to the new outline. Aluminum epoxy putty is best for filling in or aluminum inserts may be fitted. When filing, care must be taken not to break through the port wall. If you do, however, the damage may be repaired with epoxy putty. The

shape of the transfer ports in the crankcase must accurately join the cylinder barrel transfer ports. Slide the cylinder onto the studs of each half of the dismantled crankcase and scribe the finished crankcase port openings onto the bottom of the cylinder barrel. File out and polish to the scribed outlines. Figure 6 shows the vertical section of a transfer port within the cylinder barrel. Arrangement

and dimensions of the modified transfer, exhaust and intake porting into the cylinder are shown by the diagram of an unfolded section of the cylinder barrel shown in Figure 7. The openings should be enlarged as shown and then chamfered and polished as in Figure 8. Chamfering allows the rings to pass smoothly across the openings without breakage of unwanted ring vibrations that reduce sealing efficiency. A horizontal section through the cylinder barrel at the level of the exhaust and transfer ports is shown in Figure 9. Figure 10 is a horizontal section of the cylinder at the bottom of the transfer and inlet ports. Figure 11 is the vertical section through the centerline of one of the exhaust ports. Follow these outlines carefully in reworking the porting.

Dimensions for modifying the piston are shown in Figure 12. The skirt has been trimmed and the intake window in the piston skirt has been altered to the dimensions shown.

After these modifications have been made, port timing will be as shown in Figure 13. Note that transfer timing will now be 130° in duration as has been recommended for the most highly tuned racing engines.

Getting back to the piston, clearance between the piston and cylinder should be increased about .005-inch to take care of extra piston expansion. This may be done by lapping the piston into the cylinder with fine grinding compound. After lapping, be sure to thoroughly clean both piston and cylinder of all traces of abrasive.

Piston rings should be selected that have the dull black or grey “sulphate diffusion” finish. Modify them by filing a 1/64" chamfer on all four edges to reduce wear and danger of sticking. Fit the rings as usual with grinding compound and be sure that the front securing pegs are exactly in the middle of the space between the exhaust port and its neighboring transfer port.

Before we get to the cylinder head, following are some minor modifications which should be made to the crankcase assembly. Fit hardened and ground steel shims into the crank webs as shown in Figure 14. The shim surfaces must be fitted accurately perpendicular to the axis of the connecting rod bearing. Increase the connecting rod bearing end clearance so that the wrist pin end can be moved back and forth about 1/32". File the connecting rod bearing oil groove slightly larger and polish the entire surface of the rod.

To get maximum output from your engine it is necessary to raise the compression ratio. On fuel of at least 98 octane you can bring the compression ratio up to 11:1. This in turn requires a “squish” type combustion chamber to create the necessary turbulence for good combustion. Both of these modifications can be accomplished by partially filling the combustion chamber with aluminum weld and remachining to the dimensions shown in Figure 15. Welding is more easily done on an older model cylinder head which has been sand cast. If a head from the Jawa 250 Model 557 scrambler engine is used, the front stud holes will have to be relocated 5/64" to the rear, and the diameter of the flange which centers the head on the cylinder must be reduced to fit your barrel. As you proceed with the machining, the compression ratio may be checked by assembling the head with the piston in place at top dead center. Pour light oil from a graduated measure into the spark plug opening. At an 11:1 compression ratio, 25cc or 0.845 oz. will just fill the combustion chamber half way up the threads in the spark plug hole.

Your modified engine will not have a gasket between the head and cylinder barrel. After you finish machining on the head, lap the head and cylinder together with fine grinding paste. Use a thin layer of gasket cement for sealing when you bolt them up.

The drawing in Figure 16 gives accurate dimensions for fabricating an effective expansion chamber exhaust system for your modified engine. The inside tail pipe diameter should be matched closely as it has considerable influence on engine performance. The final effective length of the tail pipe section will vary from engine to engine. The 9-27/32" length is an approximate value to use as a starting point.

A good sports carburetor with a throat diameter of 1-3/16" should be used on your modified engine. The Jikov 2928H has been well proved on Jawa trials machines, but it will have to be bored out to 1-3/16" from its stock dimension of 28mm. In machining, be careful of the throttle guide insert as reboring thins the sides considerably. After machining, relocate the mixing extension by pushing it up to its original position to extend about 5/64" from the side of the throat.

Figure 4 shows the plan view of the inlet port with the carburetor flange in place. Dimensions of a flange fabricated for the Jikov 2928H trails carburetor which can be modified for this engine are given in Figure 5.

You will need to experiment with the main jets. On a correctly modified carburetor a value somewhere between 125 and 135 on the Solex scale will be found best.

In mounting the carburetor, use an insulating asbestos material insert between the flange and the crankcase and seal it with 0.020" gasket paper. The carburetor will be used without silencer, air cleaner or butterfly valve and should be mounted away from any part which might create turbulence or restrict intake of air. An unobstructed distance at least equal to about double the diameter intake is desirable. Mount the carburetor so the float chamber is at the side of the main jet or slightly forward. If it is mounted to the rear of the jet, the mixture will lean out under hard acceleration and become too rich during braking.

At high engine speeds there may be vibration of the float causing foaming and an overflow of fuel. If you suspend the float independently on some form of soft spring, these vibrations can be effectively damped out.

The increased compression ratio will require an ignition advance set 5/64 to 7/64" before TDC. The contact breaker cam and generator armature must run true within .008". Smooth the commutator with fine abrasive cloth to minimize brush vibration and sparking. Set breaker point gap at .012" to .016". Pal S-14-15, Champion LA11 or similar good grade of competition spark plug should be used.

Check the clutch spring rates and select a set that have no more than 4 Vi-lb. difference in value when fully compressed. Assemble them with a 1/32" washer under each to increase their pressure on the clutch. The bottom inner clutch plate which has the cork inserts should be modified by bending the inner carrier claws outward as shown in Figure 17 to prevent danger of jamming and locking the clutch. Late-model engines already have this modification.

In order to get good engine cooling you should replace the wide front mud guard with a narrow one made to closely follow the tire circumference about 3/4" away from the tread.

Use a good grade of heavy-duty oil made for competition 2-strokes and mix in the proportion of 20-1 with gasoline as for standard machines. Do not use “selfmixing” oils as the higher solubility of these oils detracts from their lubricating qualities at the higher temperature range in which your modified engine will operate.

The tips we have given here for modifying the Jawa 250 come from the factory and have been thoroughly checked out and tested on works machines. If you follow them carefully you should have a machine of potent output that will perform competitively against others in its class. •

View Full Issue

View Full Issue

More From This Issue

-

The Service Department

December 1962 By Gordon H. Jennings -

Cycle Round Up

December 1962 By Joseph C. Parkhurst -

37 Th International Six Days Trial

December 1962 By Sloniger -

A Cycle World Classic

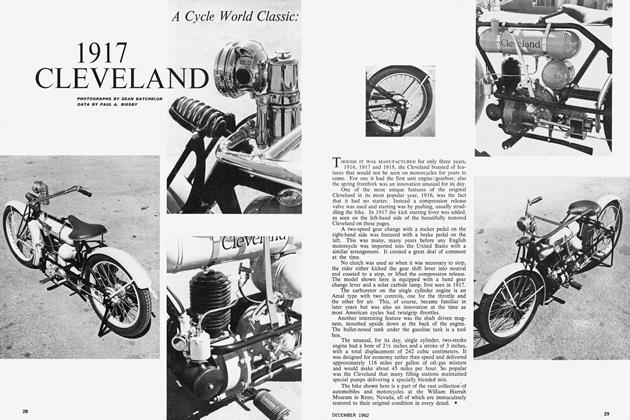

A Cycle World Classic1917 Cleveland

December 1962 By Paul A. Bigsby -

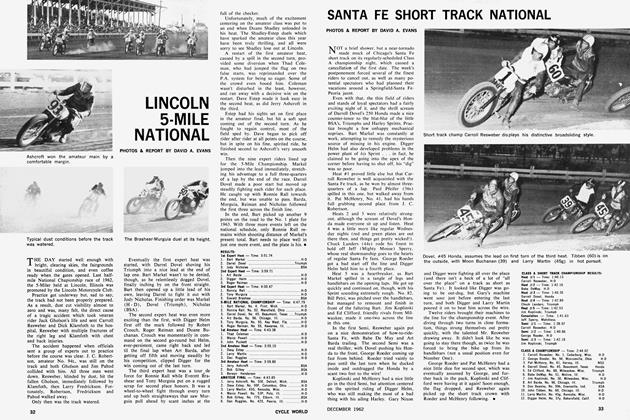

Lincoln 5-Mile National

December 1962 By David A. Evans -

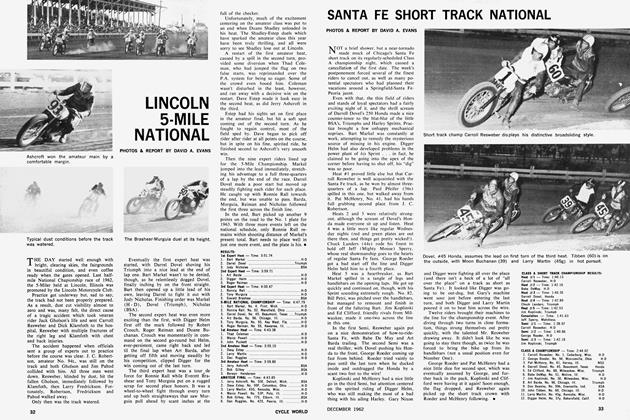

Santa Fe Short Track National

December 1962 By David A. Evans